Flip stand

A technology of turning racks and turning discs, applied in the field of turning racks, can solve problems such as hidden safety hazards, difficulty in positioning workpieces, time-consuming and labor-intensive problems, and achieve the effects of eliminating hidden safety hazards, reducing labor intensity, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

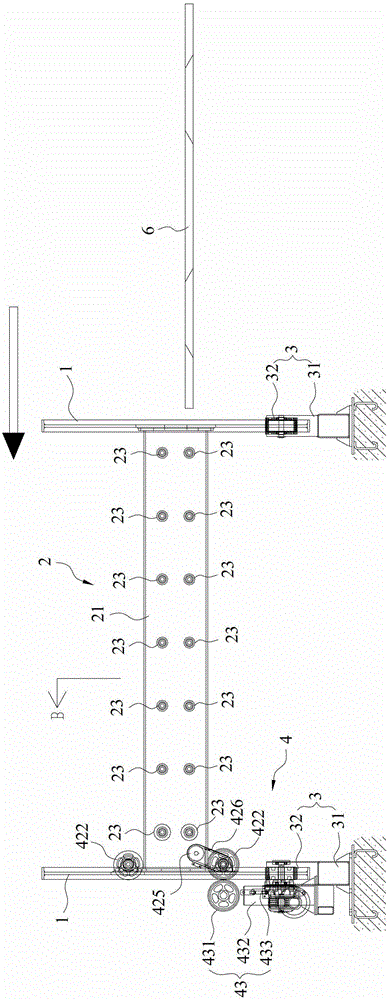

[0025] In order to further illustrate the principle and structure of the present invention, preferred embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

[0026] When describing the orientation in the present invention, the direction in which the welded workpiece flows is the same or the opposite direction is taken as the longitudinal direction, and the orientation perpendicular to the flow direction of the welded workpiece in the horizontal plane is taken as the transverse direction.

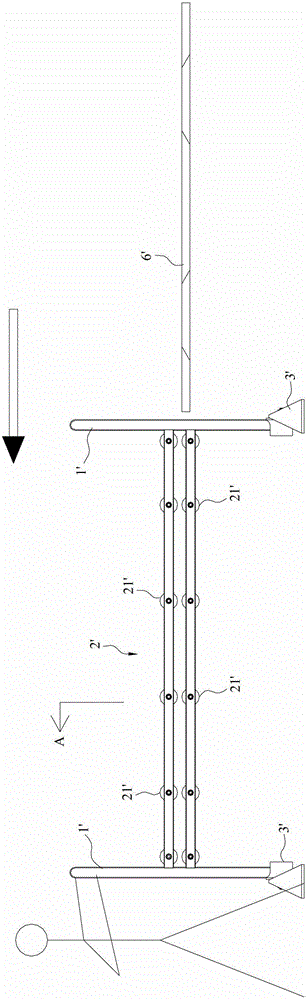

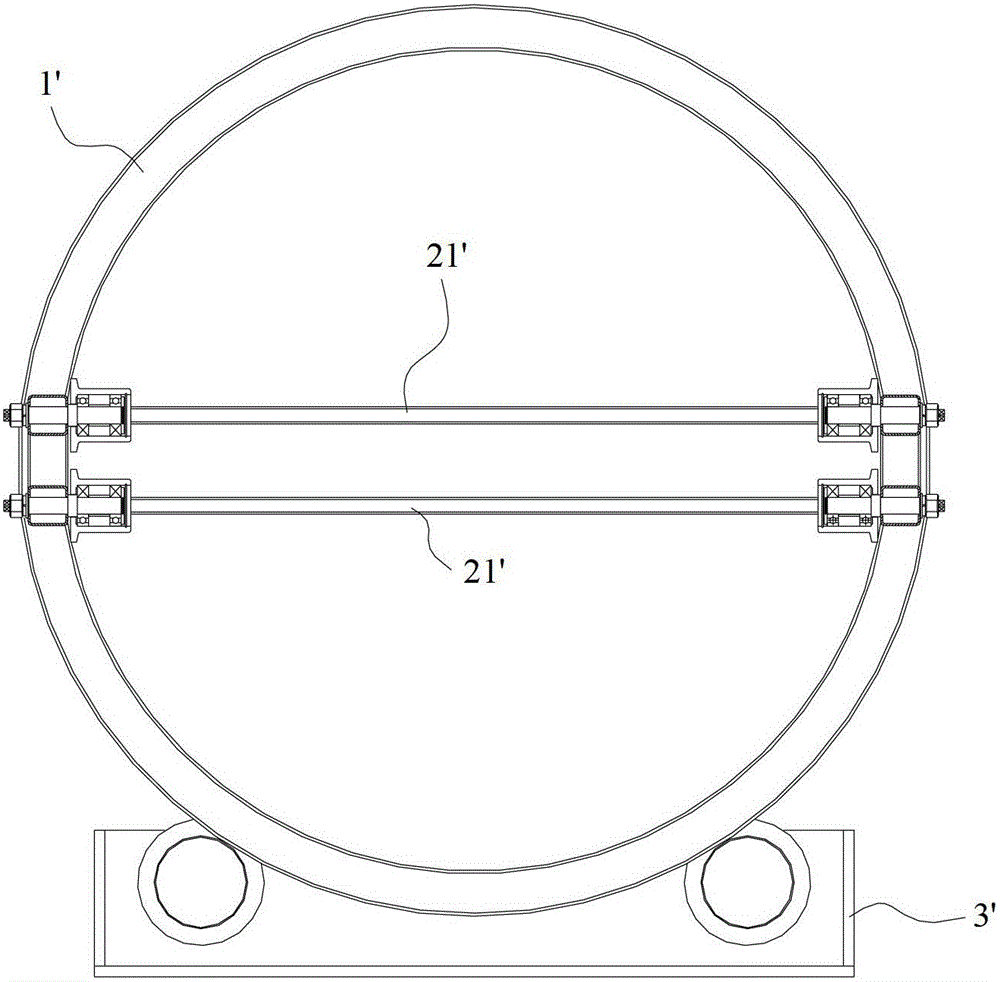

[0027] refer to image 3 and Figure 4 , The reversing frame of the present invention includes: two reversing discs 1 , a conveying frame 2 , two rollers 3 , a transmission drive mechanism 4 and a reversing drive mechanism 5 .

[0028] Both turning disks 1 are in a circular structure, and at least one turning disk 1 is provided with a circle of conveyor belt on its outer peripheral surface. The conveyor belt can be a belt or a cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com