Electric drive unit for X type gun

A technology of electric drive unit and drive body, which is applied in the direction of welding power supply, resistance welding equipment, manufacturing tools, etc., can solve the problems of no such, no consideration of the position of the drive unit in the welding equipment, etc., and achieve stable maintenance and stable gun maintenance , small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

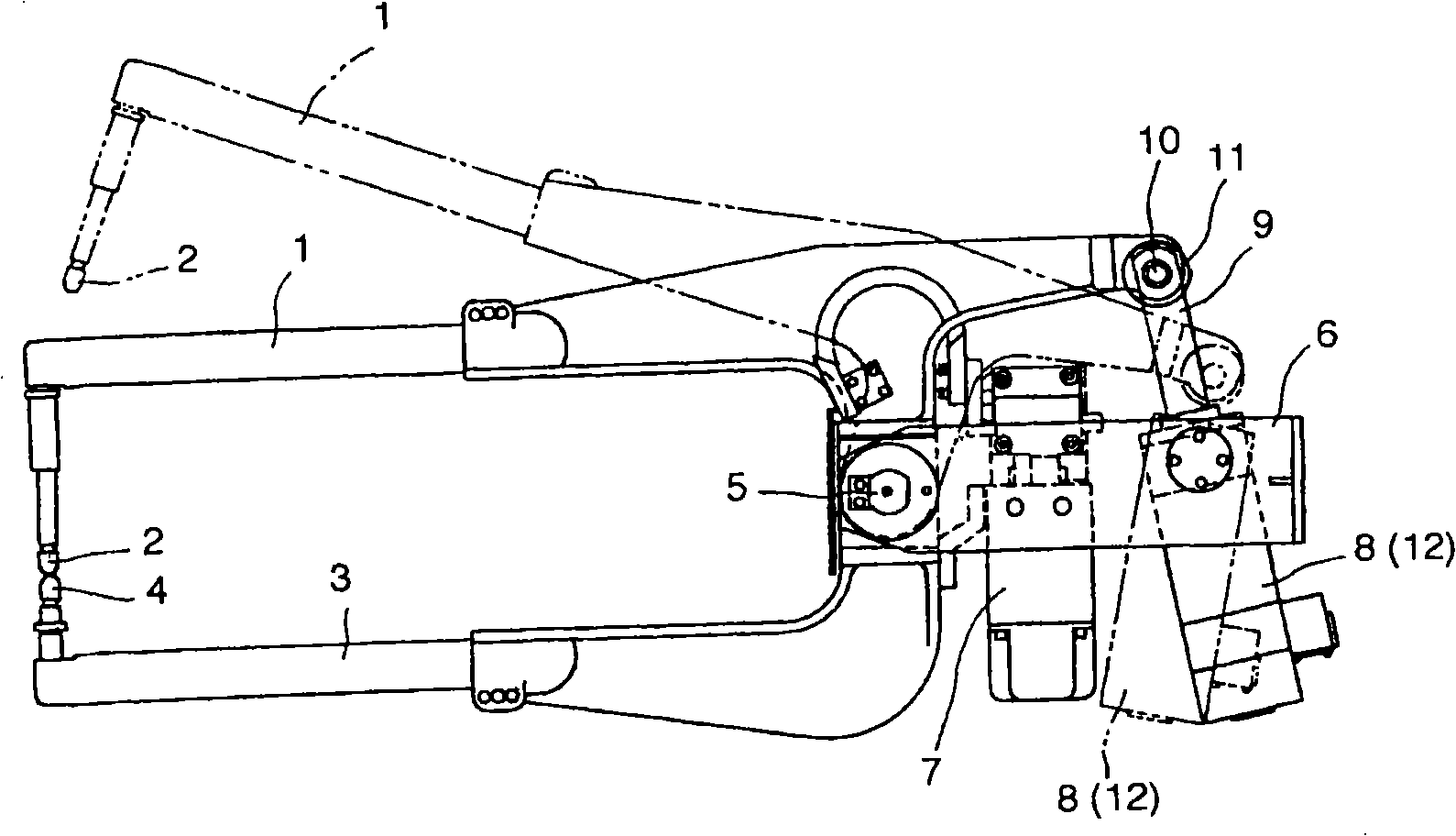

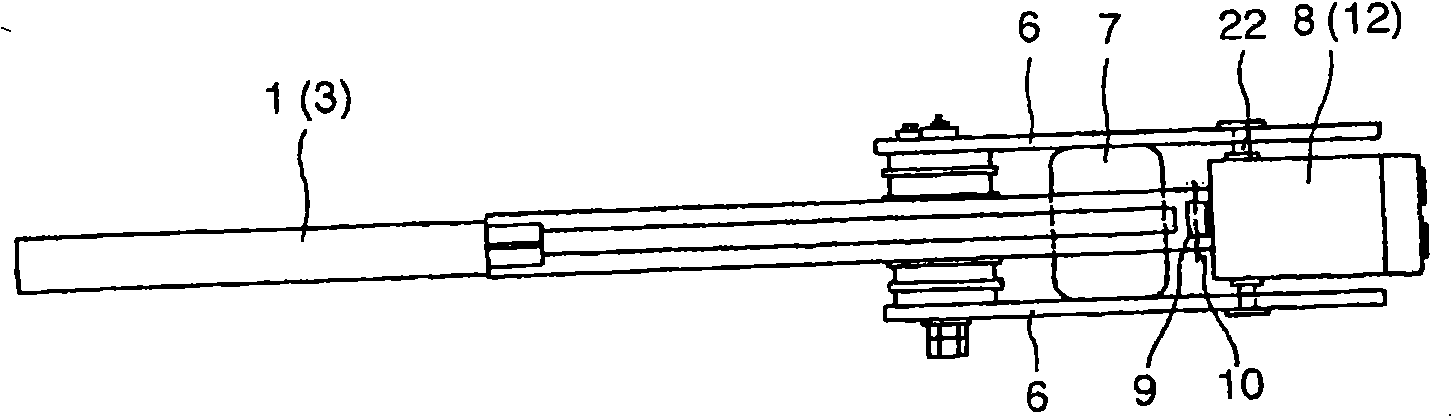

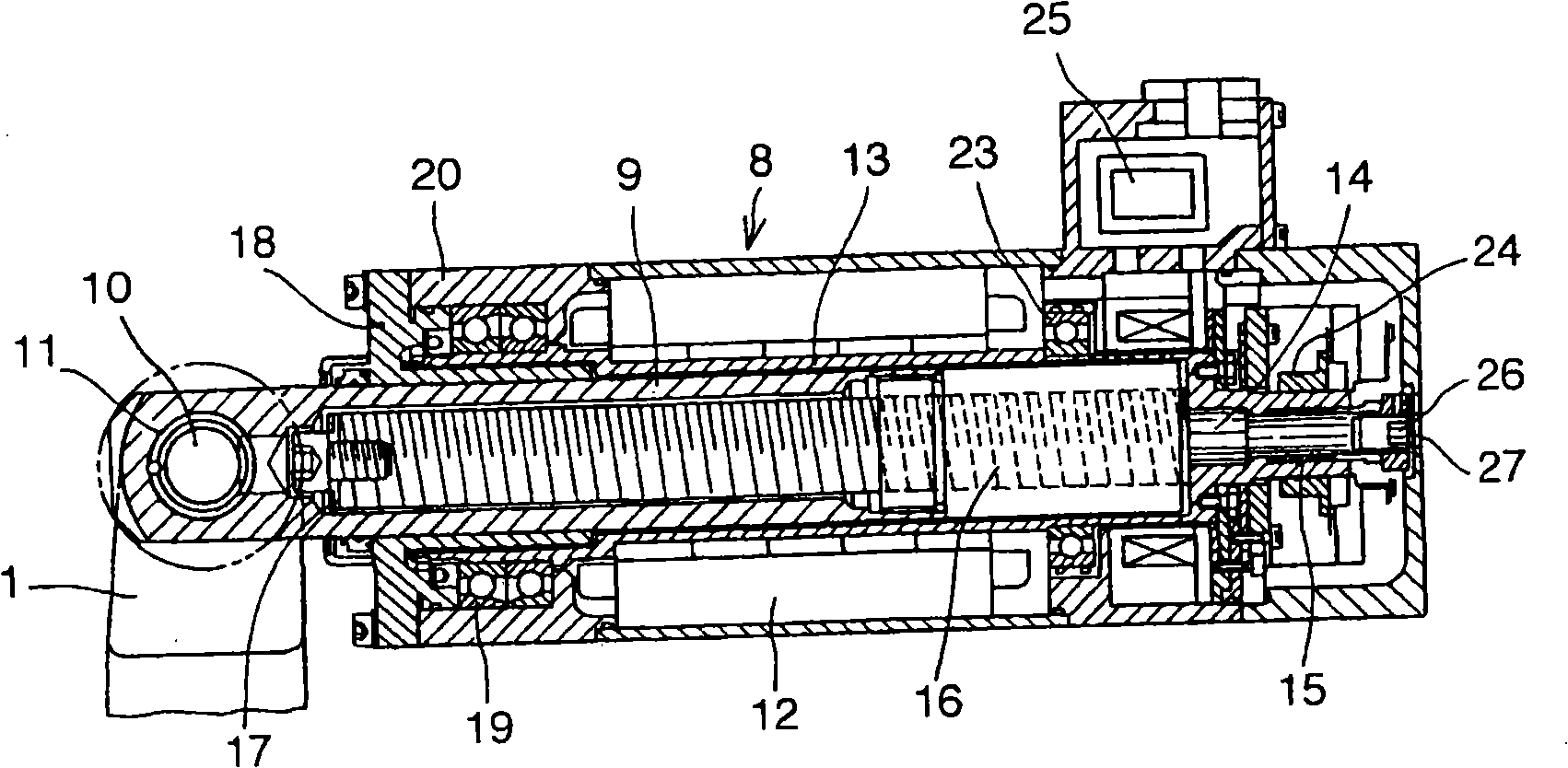

[0019] Now refer to the attached Figure 1 to Figure 4 , describing an electric drive unit for an X-gun according to a first embodiment of the invention.

[0020] figure 1 is a side view of an X-type electron gun with an electric drive unit, in which the motor and the pressure applying drive are combined with each other, figure 2 for figure 1 The plan view of the X-type electron gun in, image 3 for as figure 1 A longitudinal section view of the electric drive unit of the main components in, and Figure 4 for image 3 Plan view of the electric drive unit in .

[0021] exist figure 1 with figure 2 Among them, 1 represents a rocker arm, which is an electron gun arm with an electrode 2 at the tip, and 3 is a fixed arm, that is, another electron gun arm with an electrode 4 opposite to the electrode 2 at the tip.

[0022] The middle part of the rocker arm 1 is pivotally supported by the tip end of the gun bracket 6 (which is connected by a pivot 5 to a not shown robot wr...

no. 2 example

[0036] Now refer to the attached Figure 5 with Image 6 , describing an electric drive unit for an X-gun according to a second embodiment of the invention.

[0037] Figure 5 is a schematic side view of an X-type electron gun with an electric drive unit, in which a pressure-applying drive body and a motor are combined with each other; and, Image 6 for Figure 5 Plan view of the X-type electron gun.

[0038] In the second embodiment, the structure of the electric drive unit in which the drive body and the motor are combined with each other due to the application of pressure and image 3 , 4 The first embodiment shown is substantially the same, its parts are denoted by the same reference numerals, and its explanation is omitted.

[0039] exist Figure 5 with Image 6 Among them, the rear end side 3' of the fixed arm 3 extends backward inside the gun bracket 6, and the end of the rear end side 3' passes through the pivots 22, 22 (which are controlled by the housing 20 l...

no. 3 example

[0042] In the first and second embodiments, such as image 3 with Figure 4 As shown, a manual operation hole 27 is located in the cover housing 8' towards a square or pentagonal processing member 26 formed at the rear end of the screw shaft 14 to form the rear end portion of the pressure applying drive body 8.

[0043] In the case where the manual operation hole 27 is provided, when the opening and closing operation of the gun arm cannot be accomplished because the pressure applying shaft 9 cannot be moved due to a failure of the power supply or the electric motor 12, etc., a tool is inserted through the manual operation hole 27, thereby The processing part 26 is rotated so that the screw shaft 14 is rotated by the rotational force of the processing part 26, and the electron gun arm is opened and closed to easily move the electron gun arm to a desired position, thereby obtaining an electric drive for the X-gun which is convenient for maintenance unit.

[0044] The square or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com