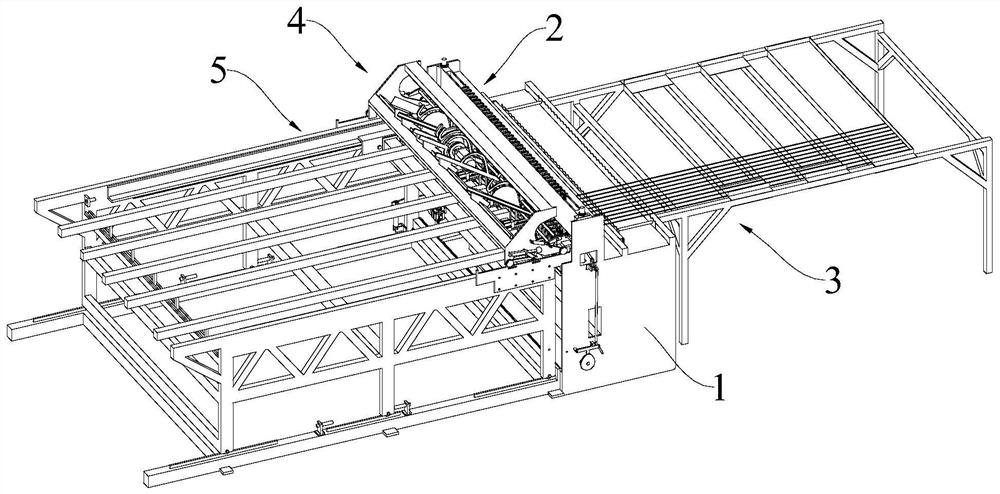

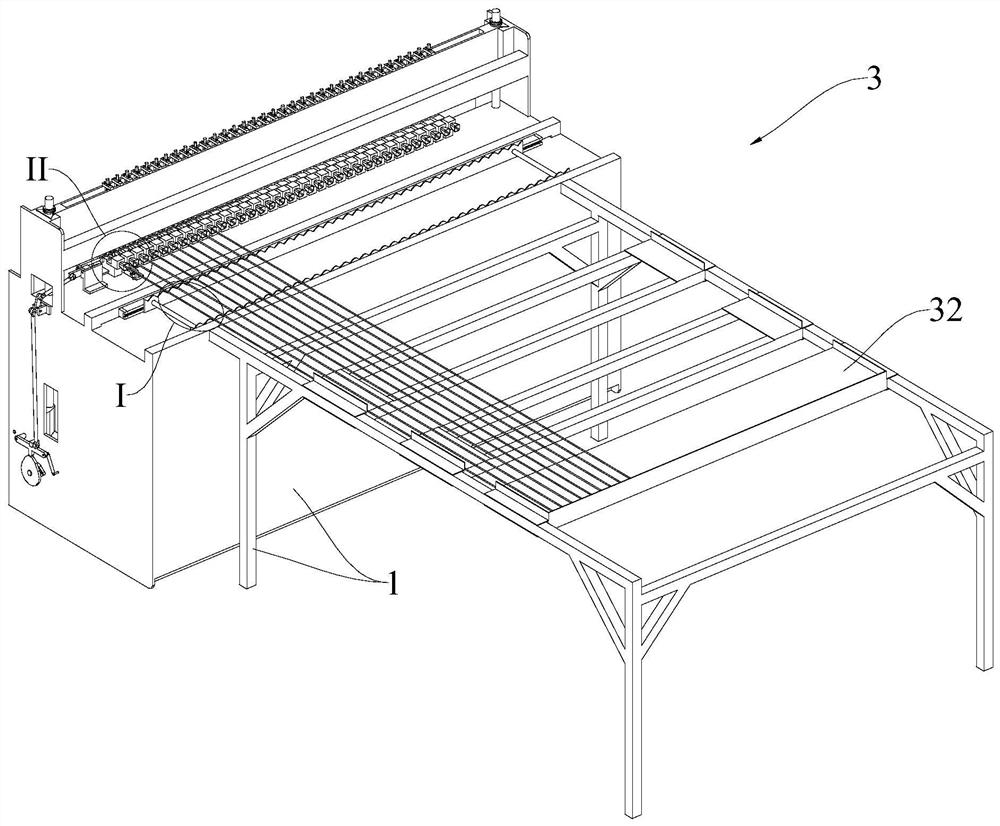

Automatic welding equipment

An automatic welding and equipment technology, applied in the field of welding processing, can solve the problems of low welding efficiency, heavy workload, and low placement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

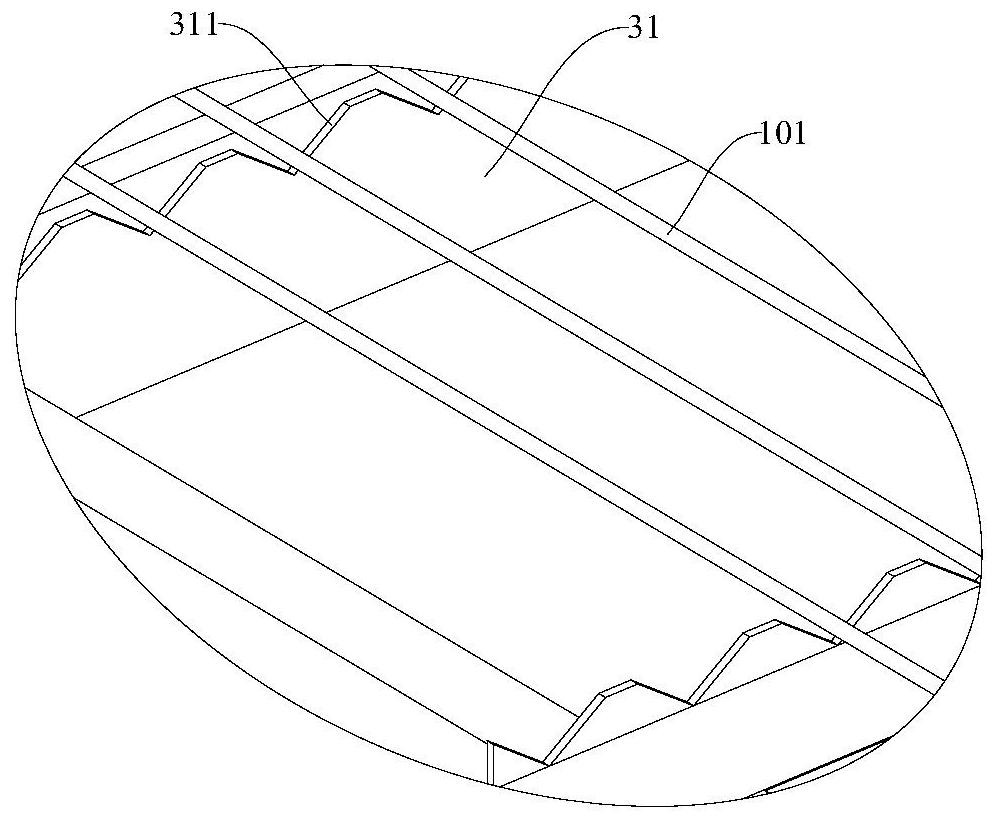

[0068] Embodiment one: if Figure 14-18 As shown, it includes a first drive mechanism 7 for driving the second welding seat 21 to move up and down and a second drive mechanism 8 for driving the push block 47 to slide longitudinally. like Figure 14 as well as Figure 17-18 As shown, the first drive mechanism 7 includes a drive shaft 71, a fixed mount 72, a first cam 73, a pull rod 74 and a compression spring 75, the drive shaft 71 is longitudinally arranged on the frame 1, and the first cam 73 is arranged on the drive shaft 71 A plurality of second welding seats 21 are longitudinally spaced on the fixed frame 72, and the fixed frame 72 is arranged on the frame 1 sliding up and down; the pull rod 74 is arranged on the frame 1 sliding up and down, and the upper end of the pull rod 74 is connected to the Frame 72; stage clip 75 is arranged on the frame 1, and forces the lower end of pull bar 74 to contact with the outer ring surface of first cam 73 (for example, stage clip 75 p...

Embodiment 2

[0071] Embodiment two: if Figure 21-22 As shown, both the pushing block 47 and the second welding seat 21 are driven by the driving cylinder 9 , so that the driving block 47 and each second welding seat 21 can be controlled to move independently by the driving cylinder 9 .

[0072] In the second embodiment, if Figure 22 As shown, the welding mechanism 2 also includes a first wiring board 22, a second wiring board 23 and a plurality of bendable conductors 24, the first wiring board 22 and the second wiring board 23 are both arranged on the frame 1, The first wiring board 22 communicates with the plurality of first welding seats 20 , and the second wiring board 23 communicates with the plurality of second welding seats 21 through a plurality of conductors 24 respectively. When the driving cylinder 9 drives the second welding seat 21 to move downward until the longitudinal rib 102 and the transverse rib 101 are pressed on the first welding seat 20, the first wiring board 22, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com