Automatic tin soldering equipment for electronic product

A technology for electronic products and automated tin, applied in welding equipment, metal processing equipment, tin feeding devices, etc., can solve the problems of low automation of tin welding equipment, low welding efficiency, cumbersome welding operations, etc., to achieve automatic welding, reduce Labor cost, simple and convenient cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

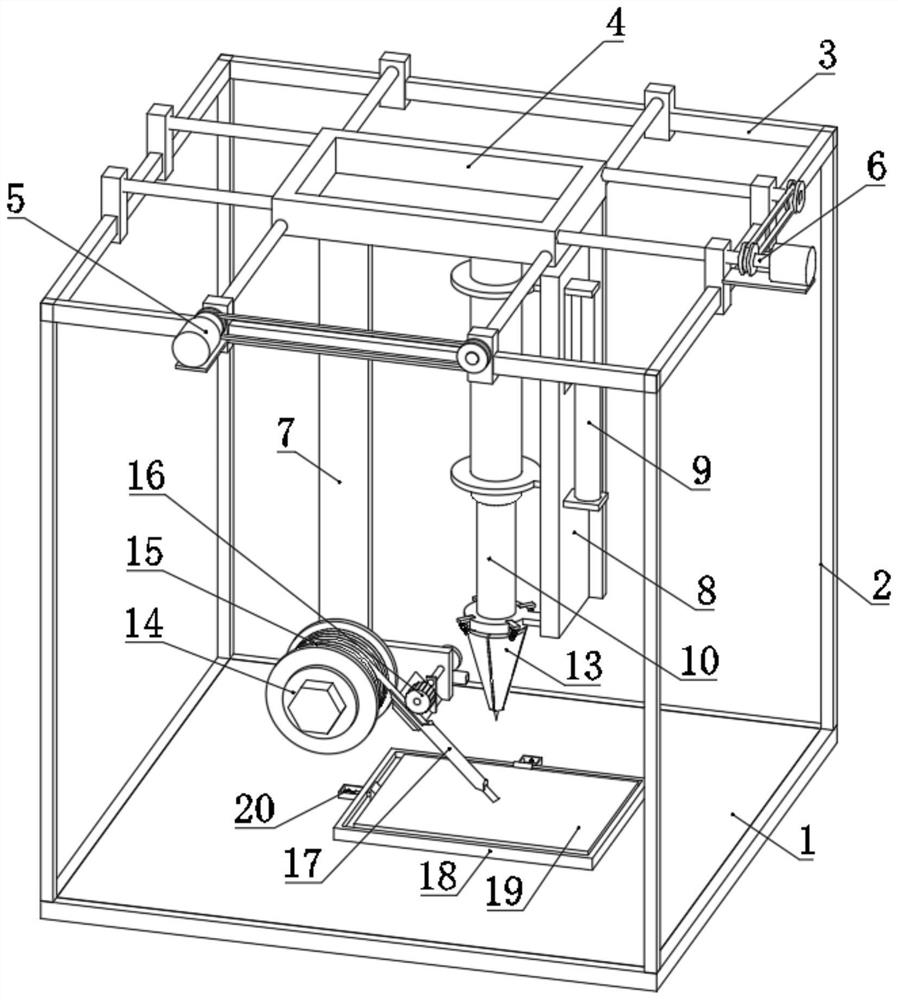

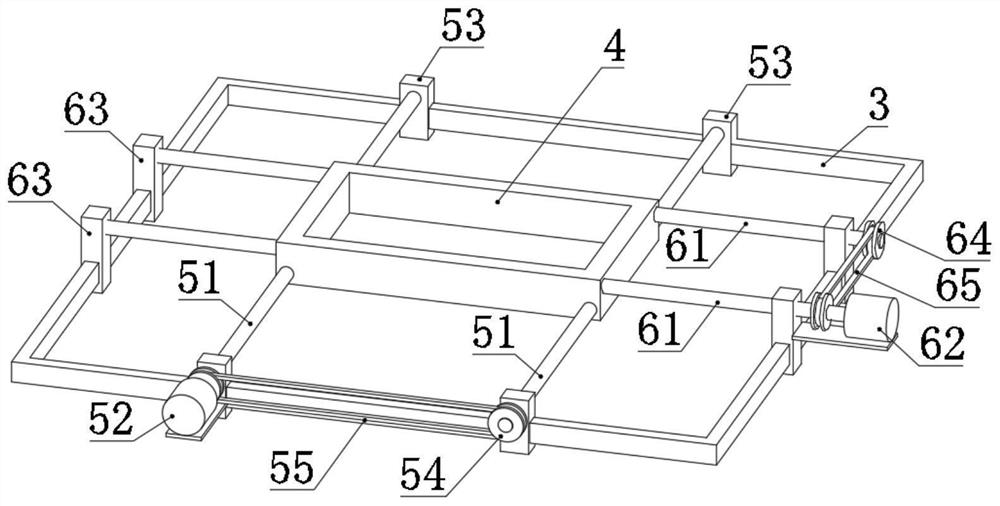

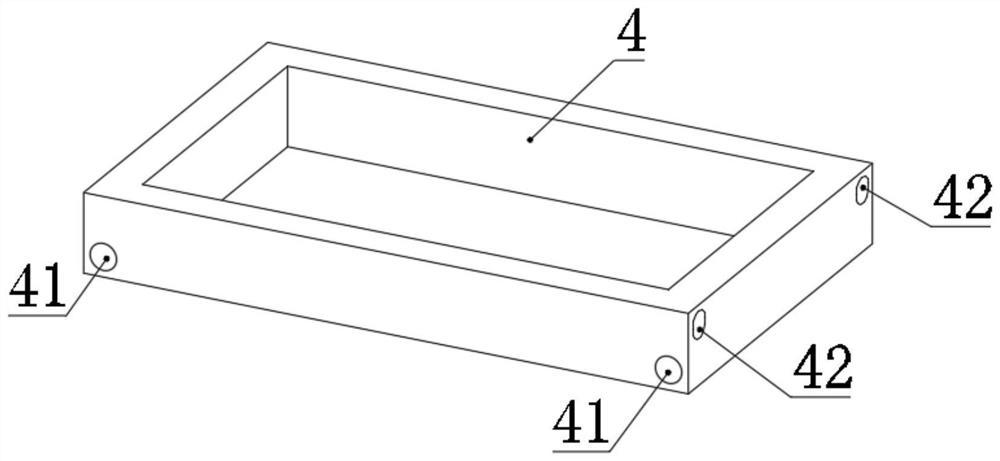

[0052] Refer Figure 1-14 An electronic automatic soldering apparatus, comprising a base plate 1, the upper side of the base plate 1 is attached to the frame 2, the upper frame 2 is attached to the top frame 3, the top side of the movable frame 3 is mounted on the first adjustment means 5 and the second adjusting mechanism 6, the top frame 3 is provided with a central carriage 4, the carriage 4 are mounted a first adjusting mechanism adjusting mechanism 5 and the second 6, the first moving frame 4 through the adjusting mechanism 5 and the second adjustment mechanism 6 drive;

[0053] Lower side of the mobile frame 4 is attached to plate 7 stand, the side stand is attached to the side plate 7 of the frame plate 8, the side of the side frame plate 8 is attached to the cylinder 9, the other end of the side frame plate 8 mounted electric iron 10, electric iron 10 includes a body 101 and a welding cone upper end 102, the body 101 by the telescopic end of the fixed ring 11 and the cylind...

Embodiment 2

[0074] Refer Figure 15-16 On the basis of the above-described embodiment, a negative pressure suction mechanism is mounted between the moving frame 4 and the guide mechanism 17, and the negative pressure gauge mechanism includes a negative pressure fan 21 mounted with the moving frame 4, Also included with the suction tube 22 mounted with the notch guide 171, the suction tube 22 is mounted with the suction port of the negative pressure fan 21.

[0075] The negative pressure fan 21 is tilted along the outer surface of the notch guide 171 by the bracket 23 and the fixed mounting. The bottom end of the suction tube 22 can also be attached to the smoking pipe to improve the effect of smoke absorption.

[0076] When the negative pressure fan 21 operates, the negative pressure is generated to absorb the smoke of the tinning tube 22 to prevent the smoke to affect the health of the person.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com