Welding device for automobile seat framework

A technology of car seat frame and welding device, applied in welding equipment, auxiliary device, auxiliary welding equipment and other directions, to achieve the effect of convenient welding operation, freely adjustable welding angle, and improved safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and embodiments.

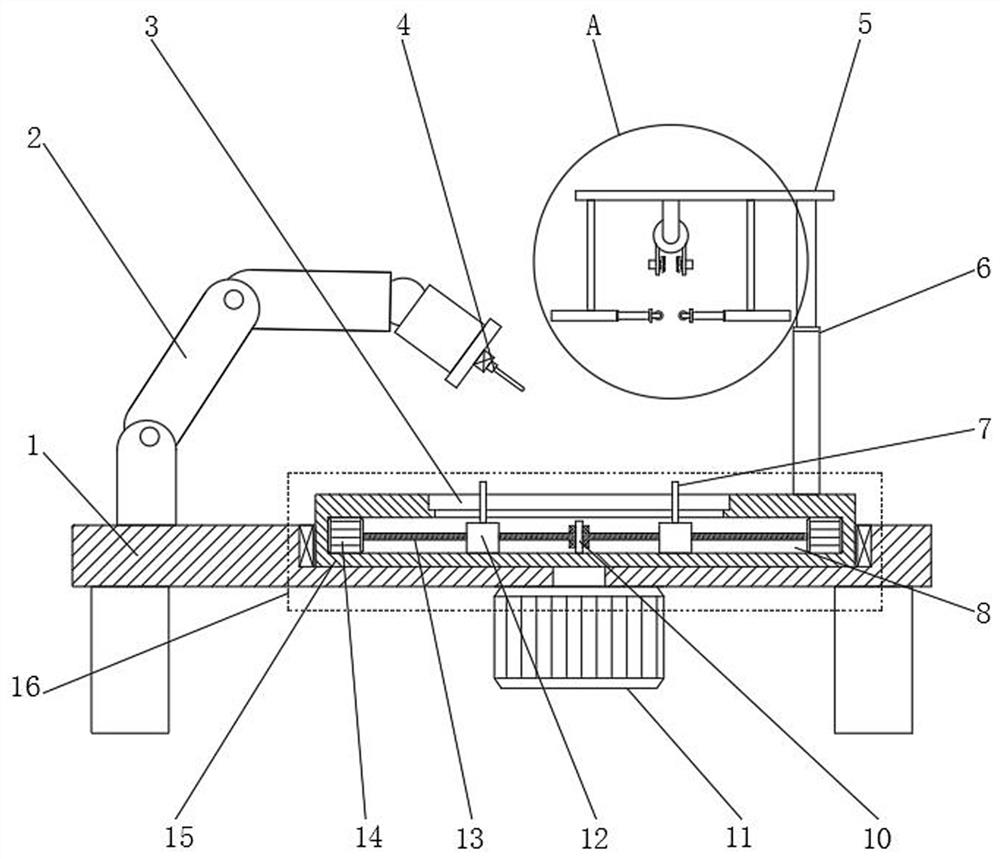

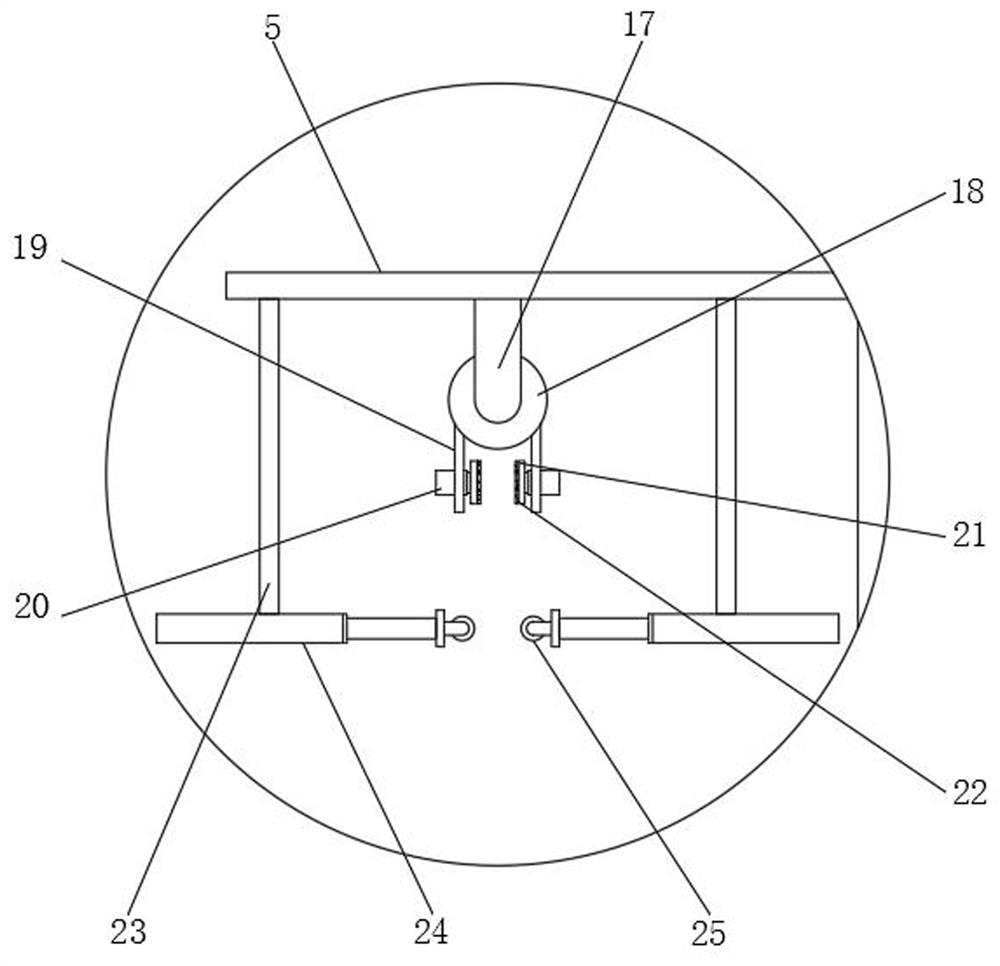

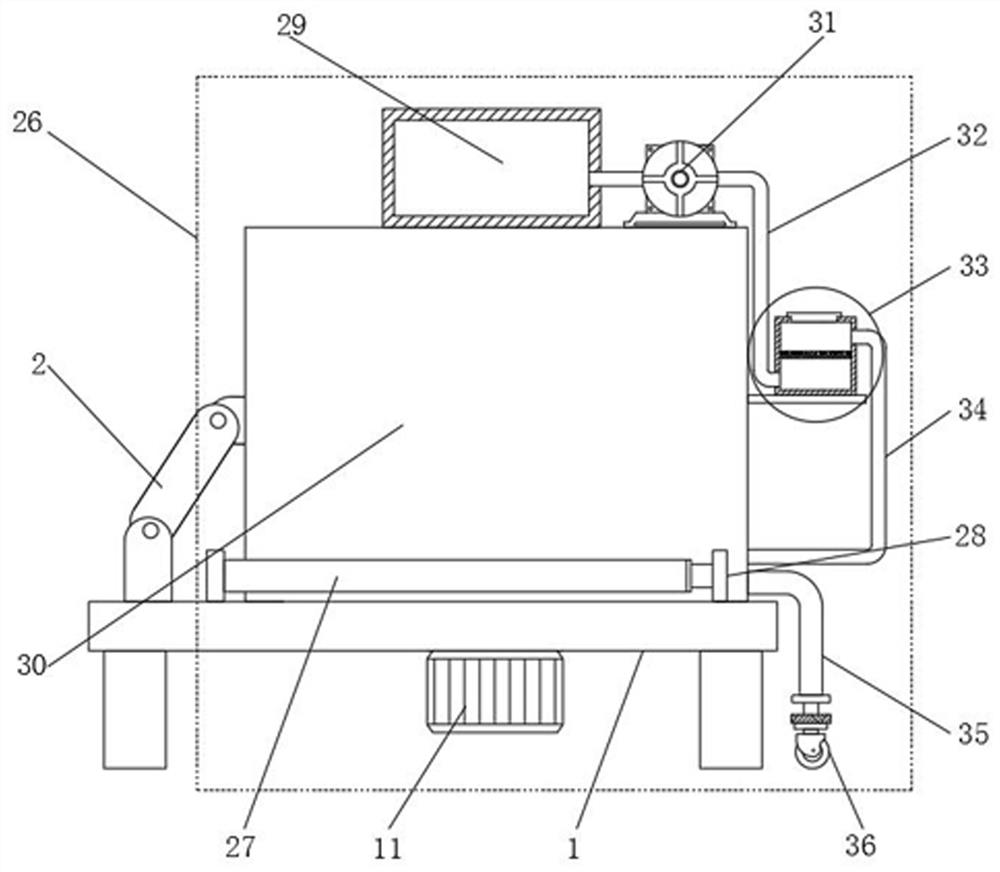

[0026] like figure 1 , figure 2 and image 3 As shown, an embodiment of the present invention provides a welding device for a car seat frame, comprising a workbench 1, the outer wall of the workbench 1 is provided with a manipulator 2, and the end of the manipulator 2 is provided with a welding assembly 4 , the outer wall of the worktable 1 is provided with a mounting groove, and the rotating disk 15 is arranged in the mounting groove. The outer wall of the other side of the worktable 1 is provided with a driving member 11. The specific structure of the driving member 11 is not limited. This embodiment Among them, preferably, the driving member 11 adopts a stepping motor, and the driving end of the driving member 11 is connected with the oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com