Welding method of tandem type solar silicon wafer group and special shelf thereof

A technology of solar silicon wafers and welding methods, which is applied in sustainable manufacturing/processing, electrical components, climate sustainability, etc. It can solve the problems of inconvenient taking of silicon wafer groups, inconsistent distances, and difficult to support and hold, and achieve high operating speed Convenient and quick, reduce fragmentation rate, easy to take effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

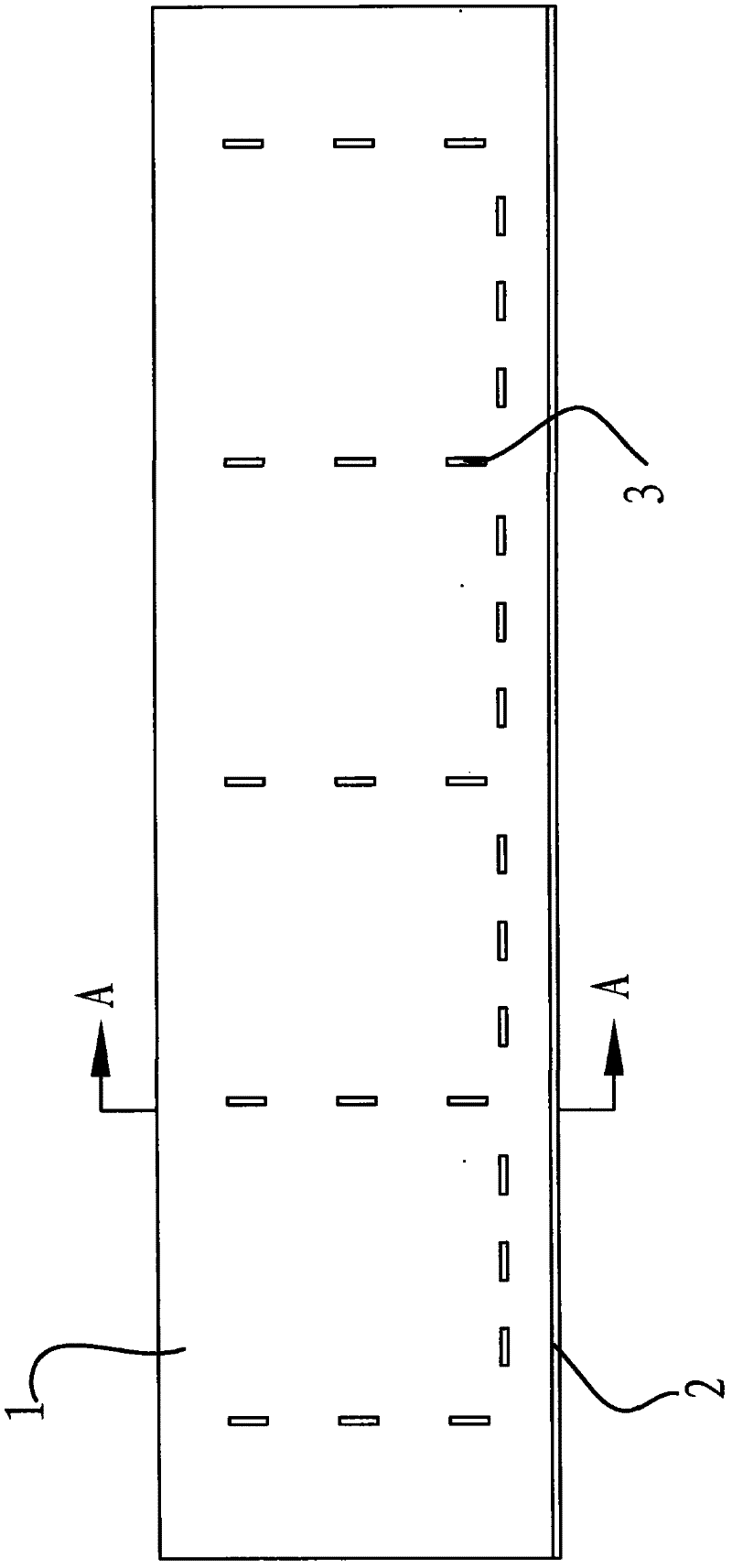

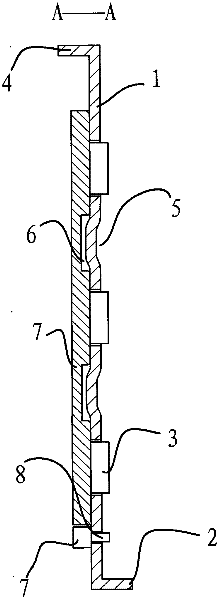

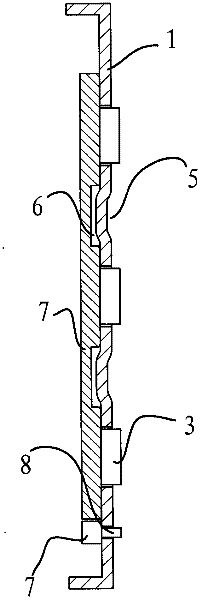

[0020] The tandem solar silicon chip group welding shelf includes a platform and a plate-shaped shelf 1, and the shelf 1 is used to naturally rest on the platform. A heating device is arranged on the back side of the platen. When the shelf 1 is placed on the platen, the shelf is located above the heating device. When the silicon wafer group is welded, the heating device is in an energized state.

[0021] The shelf 1 is provided with several sets of spacers protruding to the outside of the front surface of the shelf 1, and there are intervals between two adjacent sets of spacers in the length direction of the shelf 1, and these intervals are equal. These spaces are slightly larger than the dimensions of the silicon wafers so that the silicon wafers can fit into these spaces.

[0022] There are three spacers 3 in each group of spacers, the three spacers 3 are arranged separately along the width direction of the shelf 1, and the gaps between two adjacent spacers 3 are equal.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com