A motor integrated design simulation system and method thereof

A simulation system and integrated design technology, applied in design optimization/simulation, geometric CAD, special data processing applications, etc., can solve the problems of simulation and design analysis, high cost, waste of design resources, etc., and achieve the effect of improving design efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

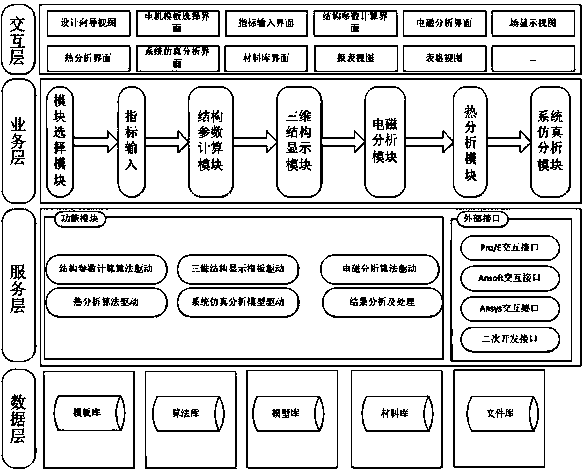

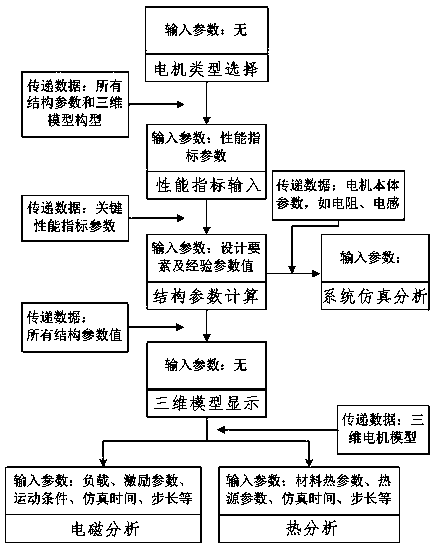

[0044] see figure 1As shown, a motor integrated design simulation system, the overall framework of the simulation system is divided into data layer, service layer, business layer and interaction layer from bottom to top; the four-layer platform architecture can achieve the separation of logic and data , showing the effect of good scalability separated from the logic;

[0045] The data layer is the knowledge base of the simulation system, which is responsible for providing a template library, an algorithm library, a material library and a database, etc.;

[0046] The service layer is responsible for providing functional support for the simulation system, and the service layer includes a series of functional modules and external interfaces; wherein,

[0047] The functional modules mainly include a design process data management modul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com