Method for hydrolyzing, separating and preparing rice starch and rice peptide using enzyme method

A technology of rice starch and rice peptide, which is applied in the field of food technology, can solve the problems of immature rice starch process conditions, low purity of rice starch, and long reaction time, and achieve low price, shortened reaction time, and wide sources. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

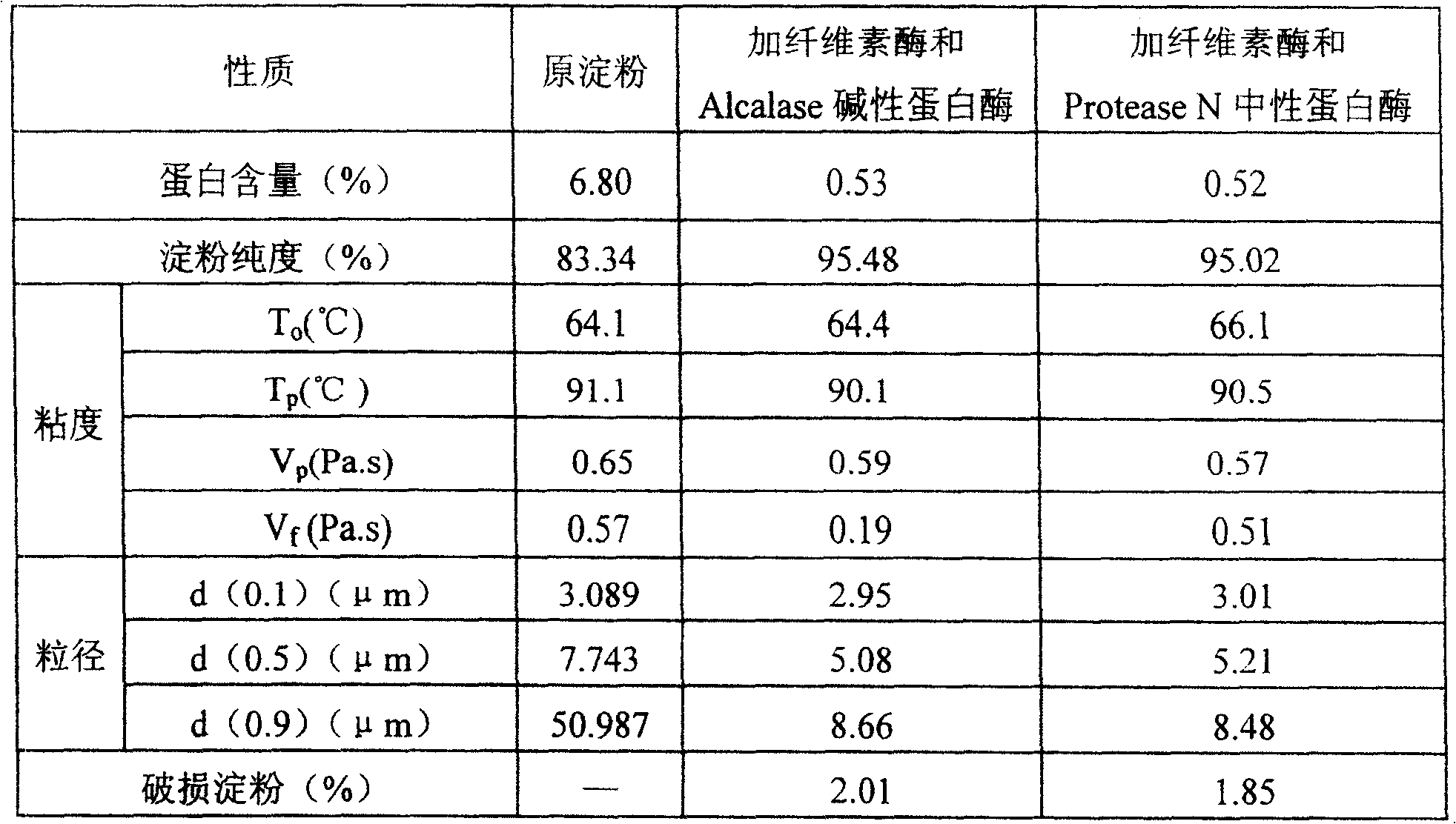

Embodiment 1

[0018] Wash 50g of rice, add 250ml of water, soak at room temperature for 18 hours, beat with a high-speed tissue grinder, 1 minute each time, 4 times in total, keep the slurry at 45°C, adjust the pH to 5, and add cellulase React 0.5g for 2 hours, adjust the pH of the reaction system to 9 after 2 hours, add Protease N neutral protease 0.5g and react for another 6 hours, centrifuge after the reaction, wash the precipitate with water several times, and dry to obtain 35g of rice starch~ 38g. The centrifuged supernatant part is subjected to rotary evaporation at about 50° C., and the evaporated concentrate is dried to obtain 2.5-2.8 g of rice active peptide.

Embodiment 2

[0020] The protease added during proteolysis was Alcalase alkaline protease, the pH was adjusted to 9.5, and the amount of enzyme added was 0.5 g, and the rest of the steps were the same as in Example 1. Rice starch and rice active peptide were prepared respectively.

Embodiment 3

[0022] Wash 50g of rice, add 250ml of water, soak at room temperature for 18 hours, beat with a high-speed tissue grinder, 1 minute each time, 4 times in total, keep the slurry at 40-60°C, adjust the pH to 5, add fiber React 0.5g~2g of primease for 1~2 hours, adjust the pH of the reaction system to 8.0~10.0 after 1~2 hours, add ProteaseN neutral protease 0.15g~0.5g and react for 2~8 hours, centrifuge after the reaction , after the sediment was washed with water several times, it was dried to obtain rice starch. The centrifuged supernatant is subjected to rotary evaporation at about 50° C., and the evaporated concentrate is dried to obtain the rice active peptide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com