A compound casting method

A composite casting and casting technology, which is applied in casting molding equipment, casting molds, casting mold components, etc., can solve the problems of complex metal casting mold processing, damage to the coating layer, and increased carbon content in castings, so as to improve the foundry workshop environment, reduce The amount of use and the effect of improving breathability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0028] Composite casting method of the present invention can be realized through the following steps:

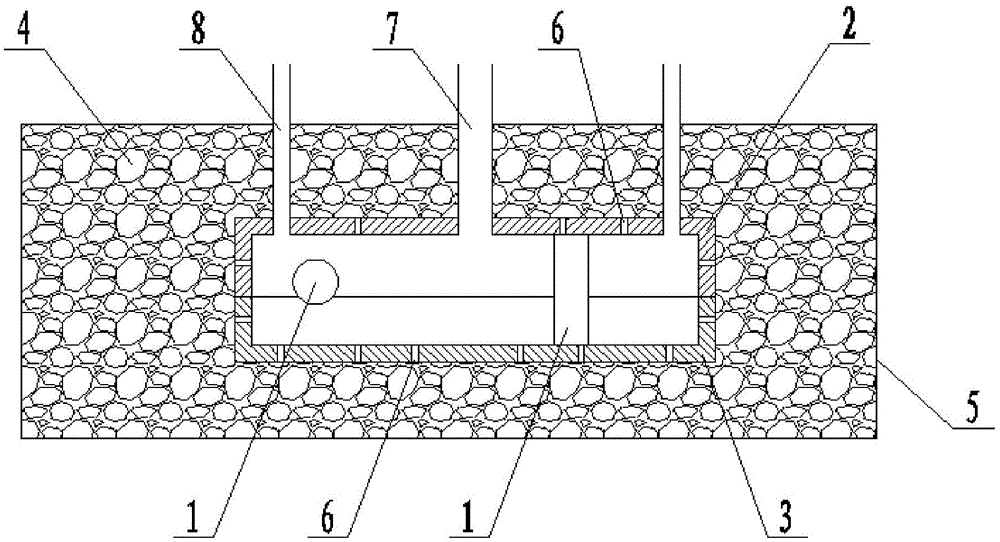

[0029] Step 1. Mold design, die making, according to the specific shape of the casting, according to the requirements of the casting process, decompose each part of the casting into the core 1, the upper mold shell 2 and the lower mold shell 3, and according to the core 1, the upper mold shell The specific shape of mold housing 2 and lower mold housing 3 can be designed and produced to suppress various upper and lower molds corresponding to core 1, upper mold housing 2 and lower mold housing 3. The upper and lower molds of the core 1 should be guaranteed to correspond to the holes of the casting. The upper and lower molds of the upper mold shell 2 and the lower mold shell 3 should not only ensure the same shape as the casting, but also ensur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com