Method for separating iron, vanadium and titanium in vanadic titanomagnetite

A technology of vanadium-titanium magnetite and vanadium-titanium-iron concentrate, which is applied in the field of vanadium and separation of iron and titanium in vanadium-titanium magnetite, which can solve the problems of low reaction temperature, low yield of vanadium element, high temperature resistance of equipment, etc. problem, to achieve obvious economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] The process of the present invention is illustrated by taking vanadium-titanium-iron concentrate in Panzhihua area as raw material and anthracite coal powder as reducing agent.

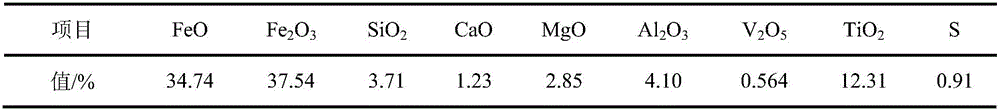

[0053] The composition of vanadium-titanium iron concentrate and anthracite coal powder is shown in Table 1 and Table 2.

[0054] Table 1 Pan concentrate composition

[0055]

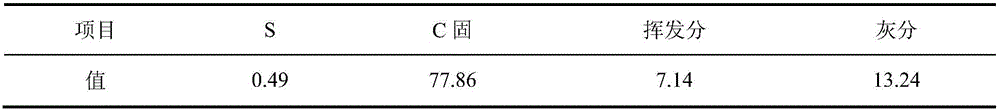

[0056] Table 2 Chemical composition of pulverized coal

[0057]

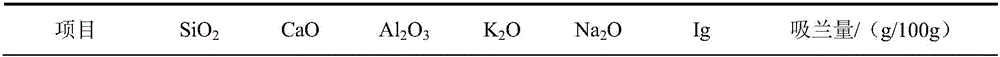

[0058] The agglomeration process needs to add a binder to improve the ball forming effect. Bentonite is selected as the binder, and the composition is shown in Table 3.

[0059] Table 3 bentonite composition

[0060]

[0061]

[0062] (1) Mix vanadium-titanium iron ore concentrate, anthracite coal powder, and bentonite according to the mass ratio of 100:21.94:1, mix them evenly, press the balls, and dry the green balls to obtain ore with a carbon-to-oxygen molar ratio of 1.2 Coal mixed pellets.

[0063] (2) The rotary kiln is used to direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com