Cell component of electric motorcar

A technology for battery components and electric vehicles, applied in electric vehicles, battery pack components, vehicle components, etc., can solve the problems of unsealing, large battery components, and affecting the performance of battery components, so as to reduce the space of the body and reduce the The effect of a small front volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

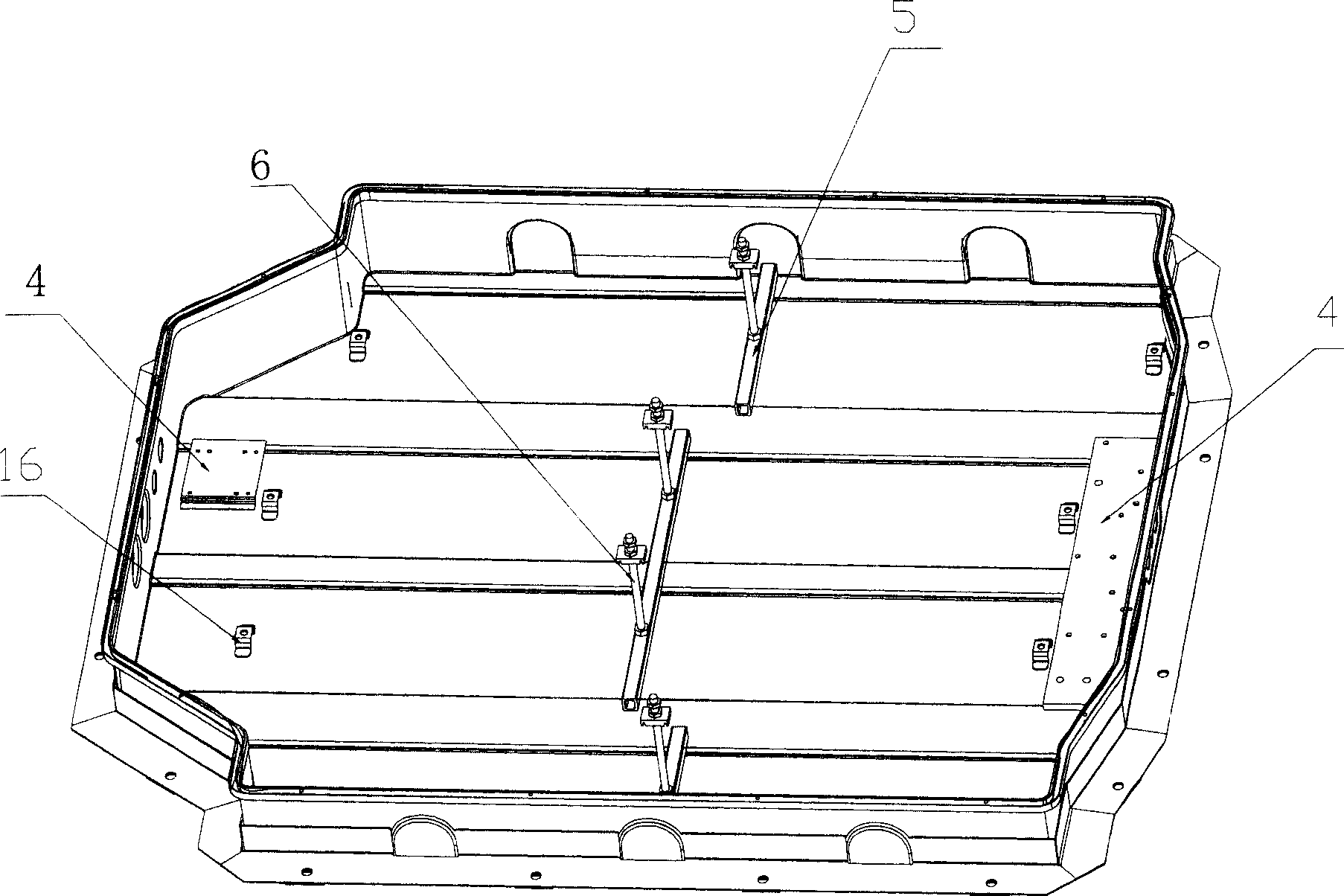

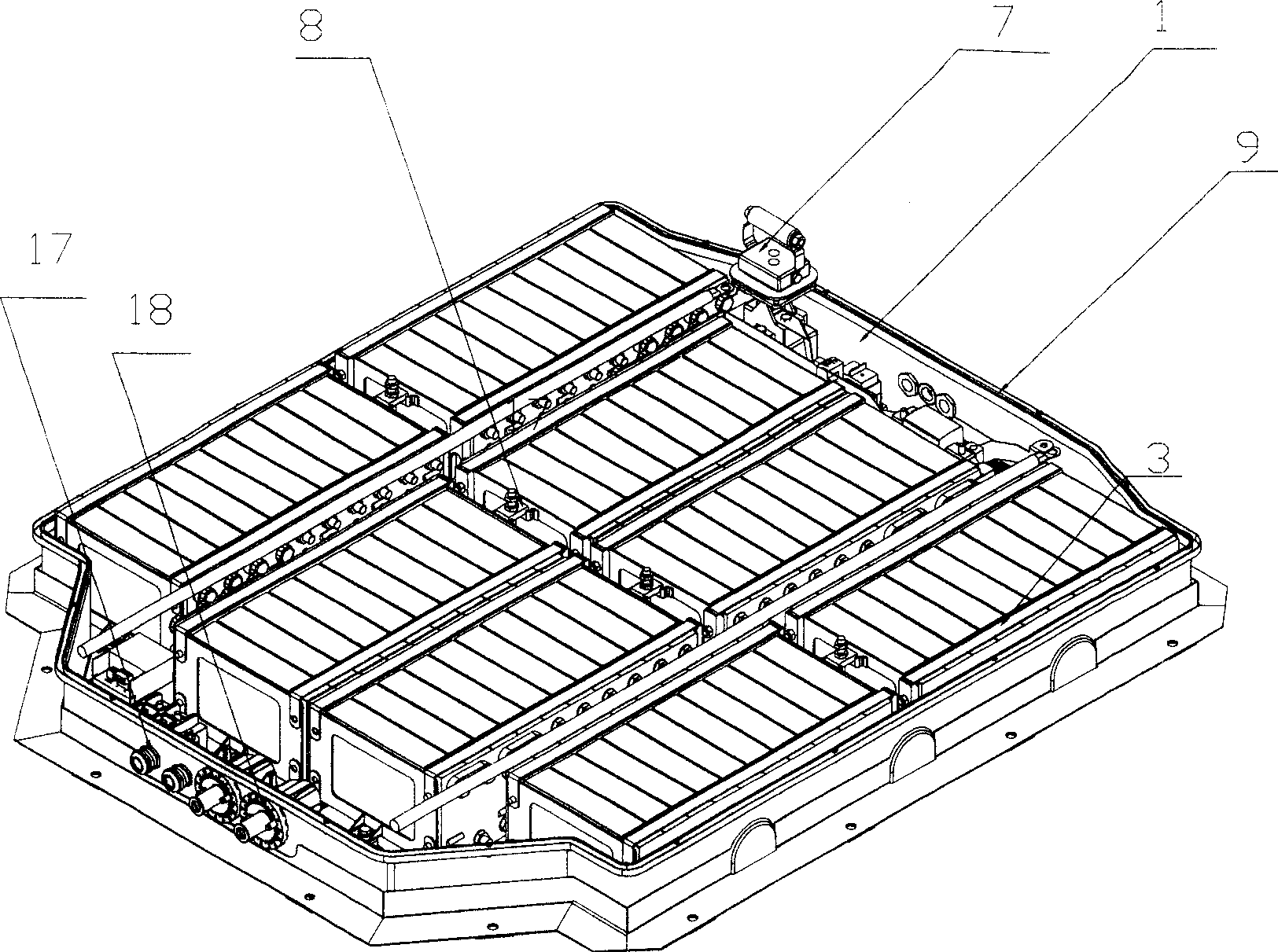

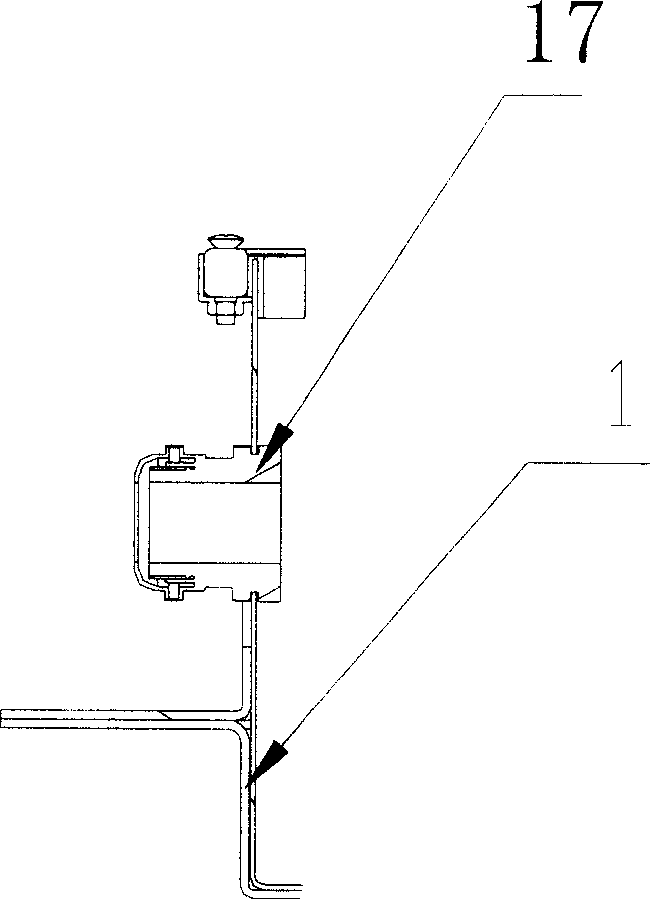

[0032] The present invention will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings. Such as figure 1 , figure 2 As shown, the battery assembly of an electric vehicle includes a box body 1 , a sub-battery pack 3 , an electrical installation plate 4 , a beam 5 , and a load-bearing screw 6 .

[0033] Such as figure 1 As shown, the structure of the box body 1 is improved on the basis of the existing box body (rectangular in cross section), and it is shown that the two corners of the rear part (near the rear suspension mounting fulcrum) are recessed forward, and the box body 1 There are at least two holes in the rear side wall. The charging cable and management harness can pass through the hole. The electrical installation plate 4 can be welded at the bottom plate of the gap between the inner wall of the rear part of the box body 1 and the sub-battery pack 3. There are screw holes on the electrical installation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com