Washing machine deceleration clutch and washing machine

A deceleration clutch and washing machine technology, applied in the field of washing machines, can solve the problems of motor leakage, excessive, water overflowing from the tub, falling to the ground between the washing machine shell and the outer tub, failures, etc., so as to achieve easy installation and disassembly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

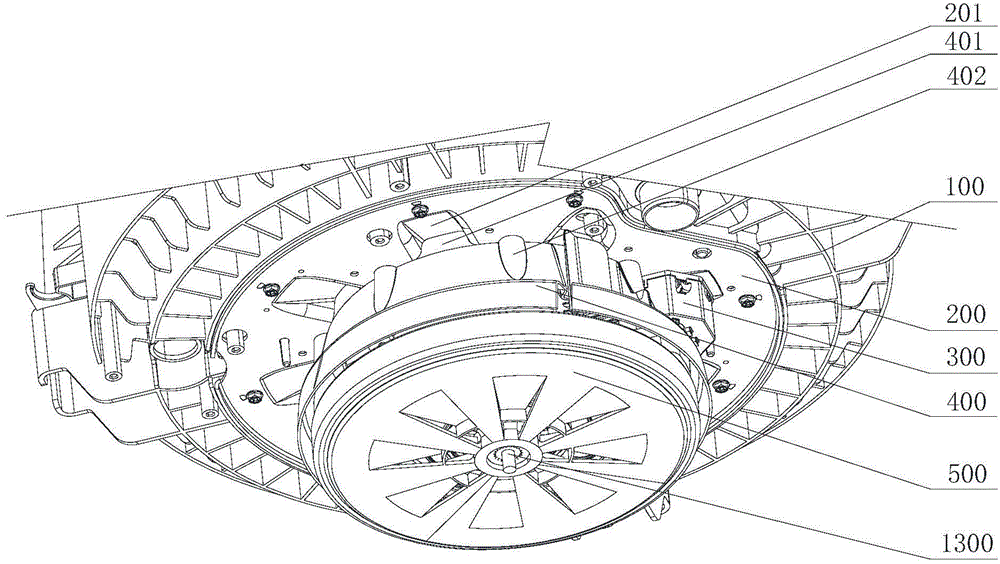

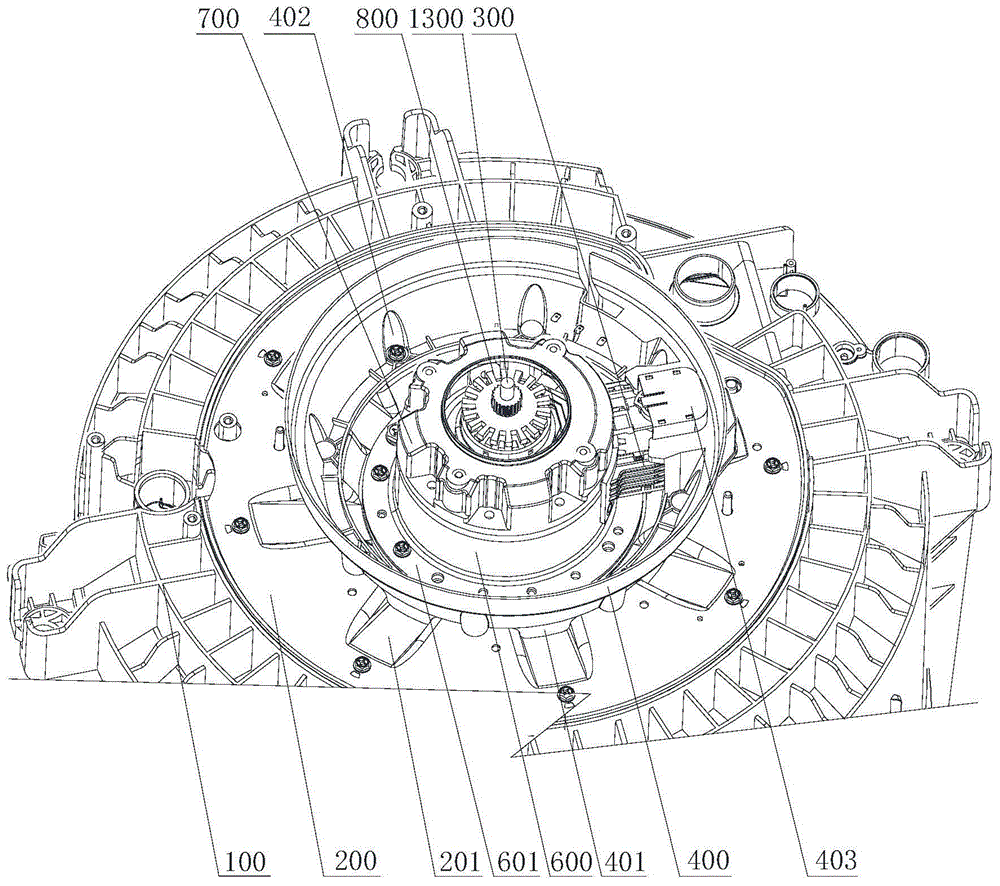

[0066] Such as figure 1 , figure 2 and image 3 As shown, a washing machine deceleration clutch described in this embodiment includes a deceleration clutch device, a mounting plate 200 and a motor 500. The deceleration clutch device is fixed on the bottom of the washing machine outer tub 100 through the mounting plate 200, and the motor 500 is arranged on The lower part of the deceleration clutch device. The deceleration clutch device includes a deceleration device and a clutch device; the deceleration device includes a gear train and a housing, the housing is fixedly mounted on the mounting plate 200, and the gear train is arranged inside the housing; the described clutch device includes an upper fixed plate, The clutch sleeve and the lower dehydration tray 800 that can slide up and down, and the clutch sleeve slides up and down to engage with the upper fixed tray and the lower dehydration tray 800 respectively to realize the conversion of washing and dehydration working c...

Embodiment 2

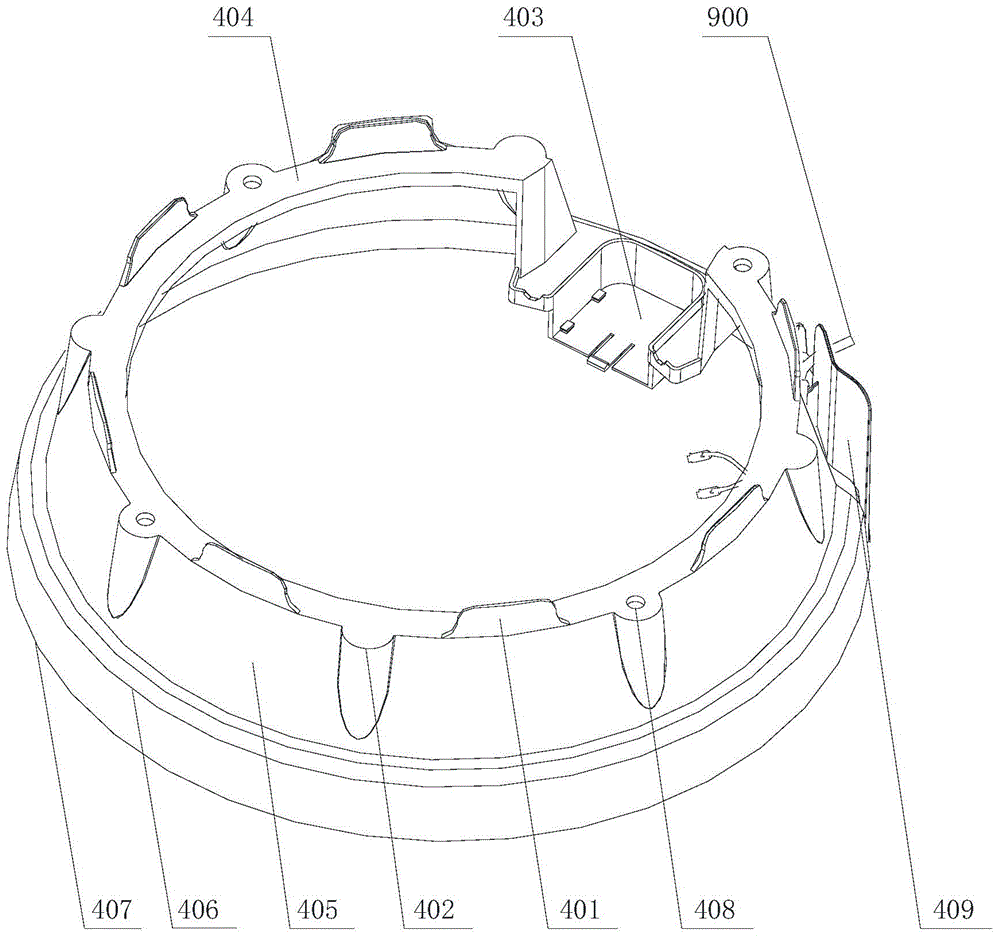

[0087] Such as Figure 1-Figure 3 , Figure 7-Figure 9 A washing machine deceleration clutch shown includes a deceleration clutch device, a mounting plate 200 and a motor 500. The deceleration clutch device is fixed on the bottom of the outer tub 100 of the washing machine through the mounting plate 200, and the motor 500 is arranged at the bottom of the deceleration clutch device. The deceleration clutch device of the washing machine of the present invention also includes a protective cover, the protective cover includes a cover body 400, and the cover body 400 is fixedly installed on the mounting plate 200; part or all of the deceleration clutch device and / or part or all of the motor 500 Set inside the cover body 400 . The cover body of the protective cover 400 of the present embodiment is installed on the mounting plate 200, does not produce influence to the installation of deceleration clutch device and motor 500, and deceleration clutch device and motor 500 are all arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com