Preparation of Si-C-N nano-composite superhard thin film

A nano-composite, super-hard technology, applied in gaseous chemical plating, metal material coating process, coating, etc., can solve the problems of unavoidable DC power arc discharge, inability to achieve uniform plating, poor uniformity or visibility, etc. , to achieve the effect of improving service life and production efficiency, good bonding strength and mechanical properties, and avoiding burns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

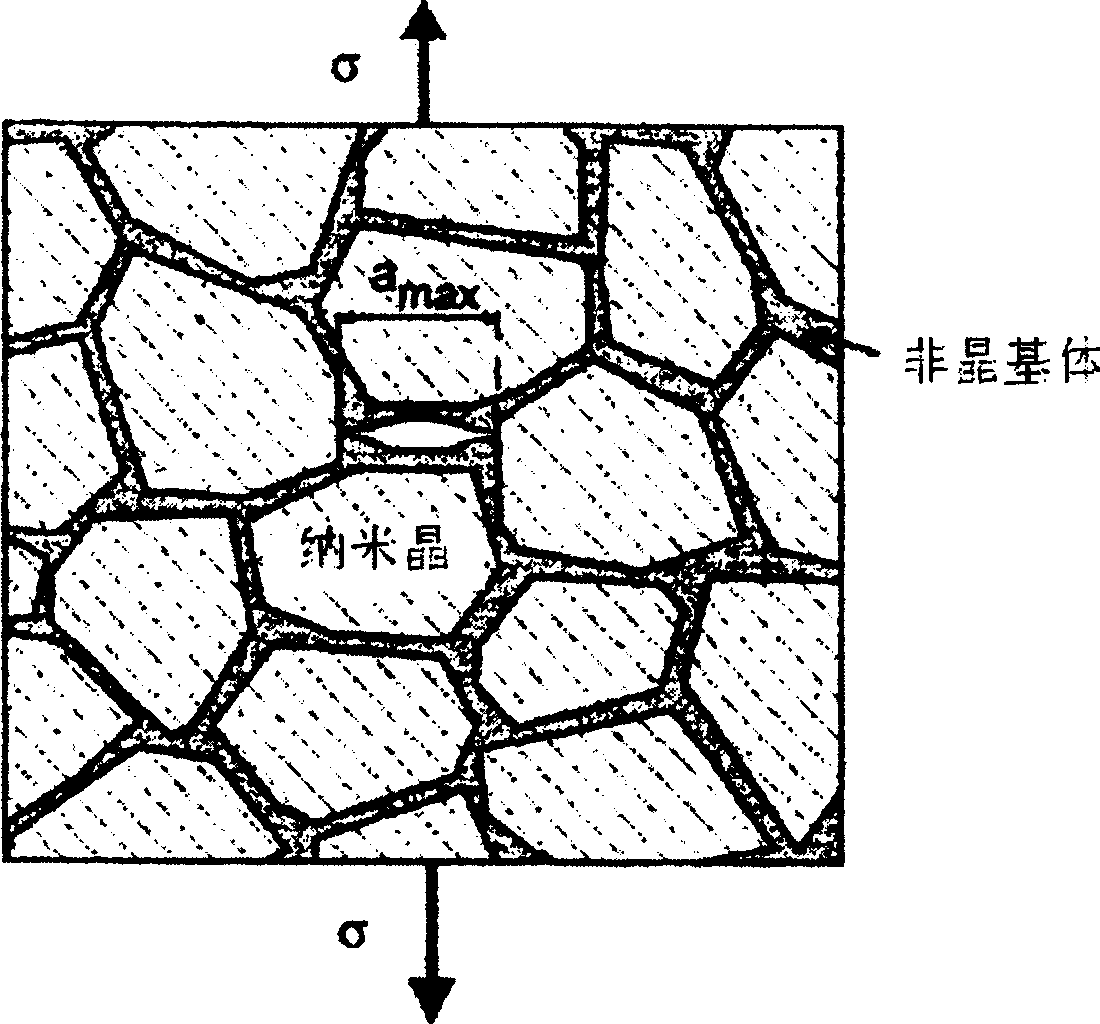

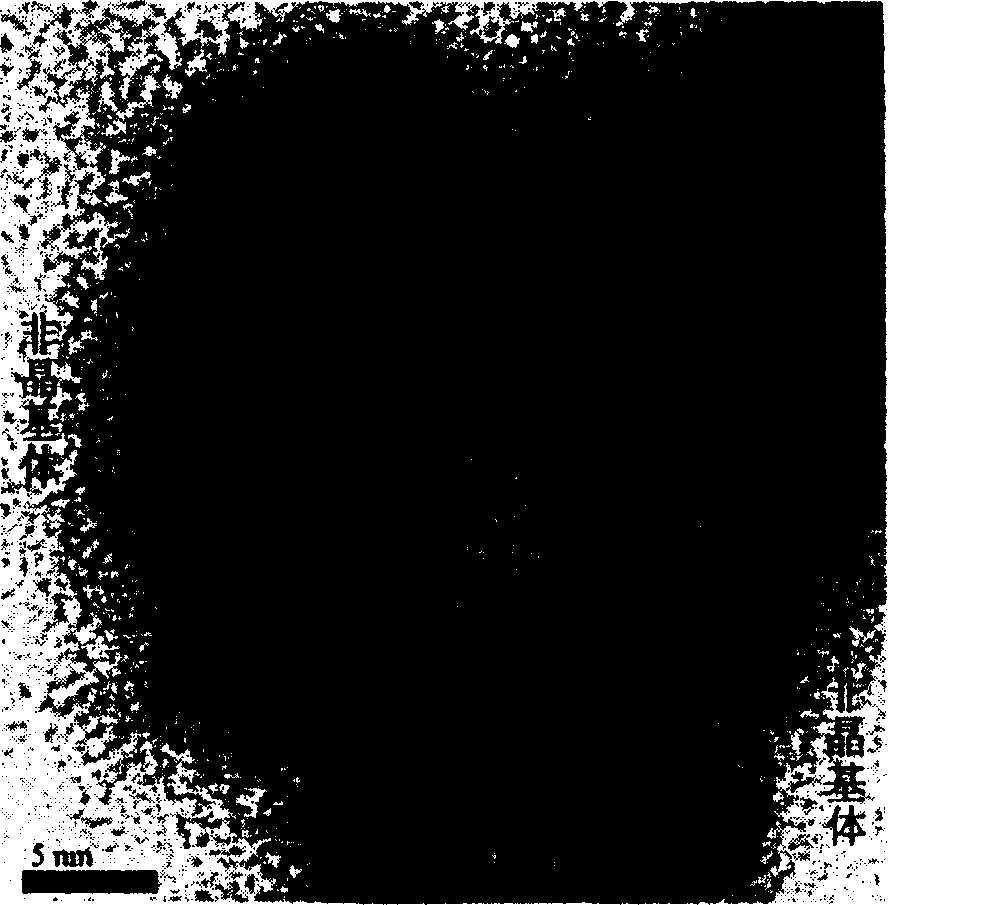

[0018] Nanocrystalline h-Si prepared by the present invention 3 N 4 / Amorphous SiCN nanocomposite superhard film material, using self-developed industrial pulse DC plasma assisted chemical vapor deposition equipment (has obtained national invention patent, patent number ZL 991159594), completed nanocrystalline h-Si in a vacuum chamber 3 N 4 / Deposition of amorphous SiCN nanocomposite superhard thin film materials.

[0019] Concrete technological process of the present invention is:

[0020] After quenching at 1170°C and tempering at 550°C, the high-speed steel with a hardness of HRC=60 is degreased and polished on the surface, then immersed in acetone for ultrasonic cleaning, and alcohol dehydration;

[0021] Then put it into an industrial pulse direct current PCVD vacuum furnace as the base material for h-Si 3 N 4 / Deposition of amorphous SiCN nanocomposite thin film materials;

[0022] Using SiCl 4 As the Si source, the pulsed DC plasma-assisted chemical vapor depos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| microhardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com