Driveway for magnetic suspension train

A technology of maglev trains and rails, which is applied to roads, tracks, buildings, etc., to achieve the effect of simplified replacement and easy separation from each other

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

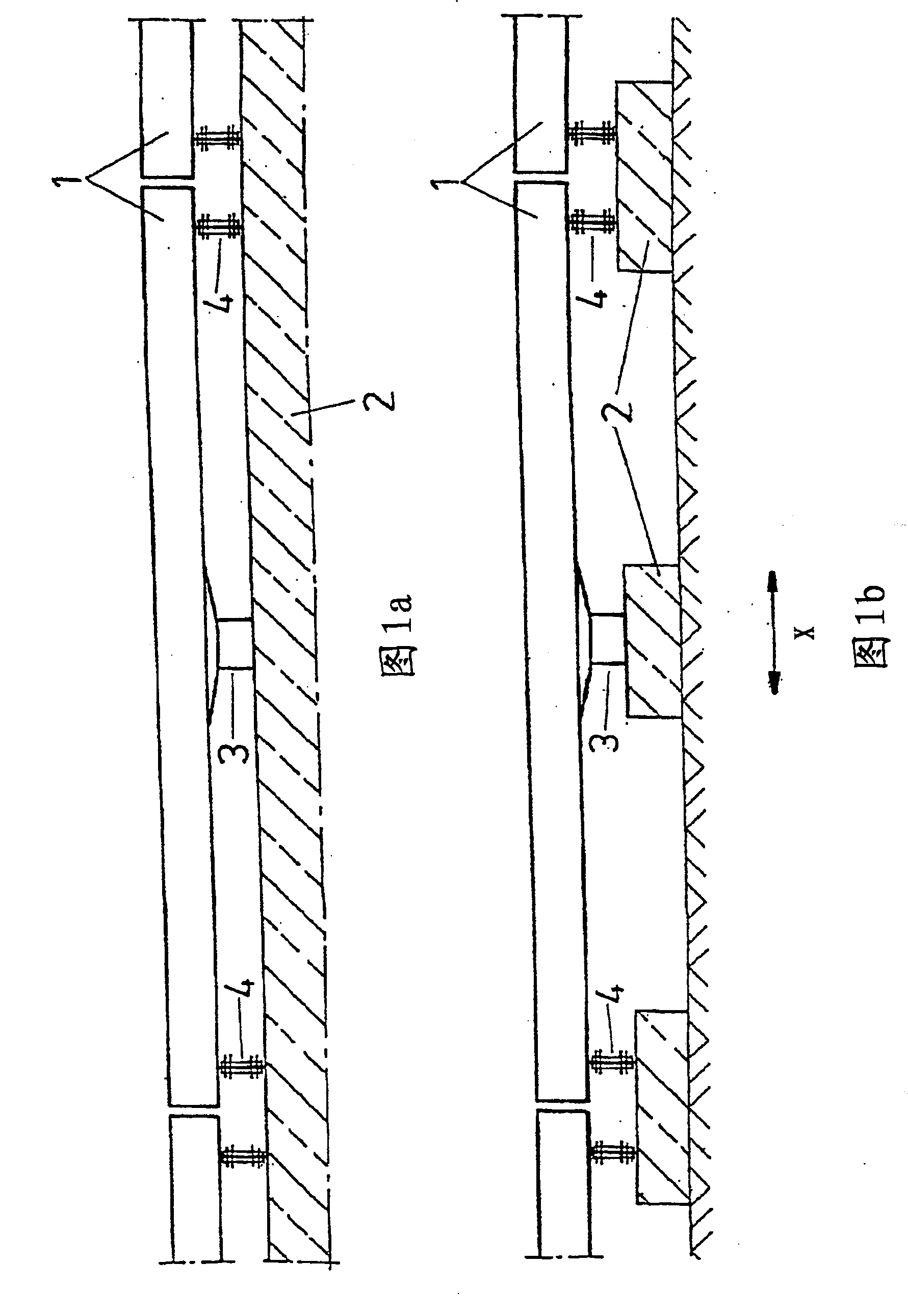

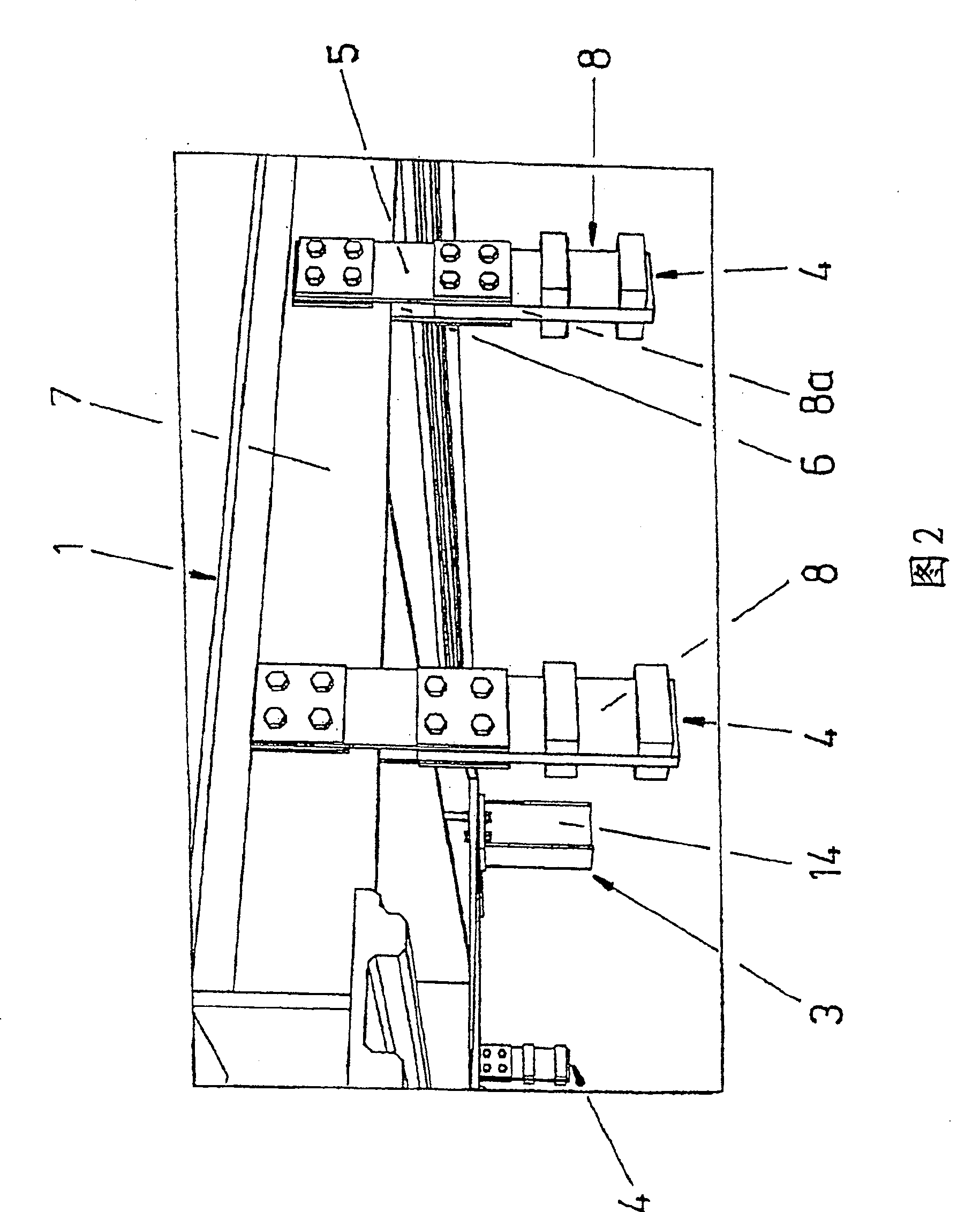

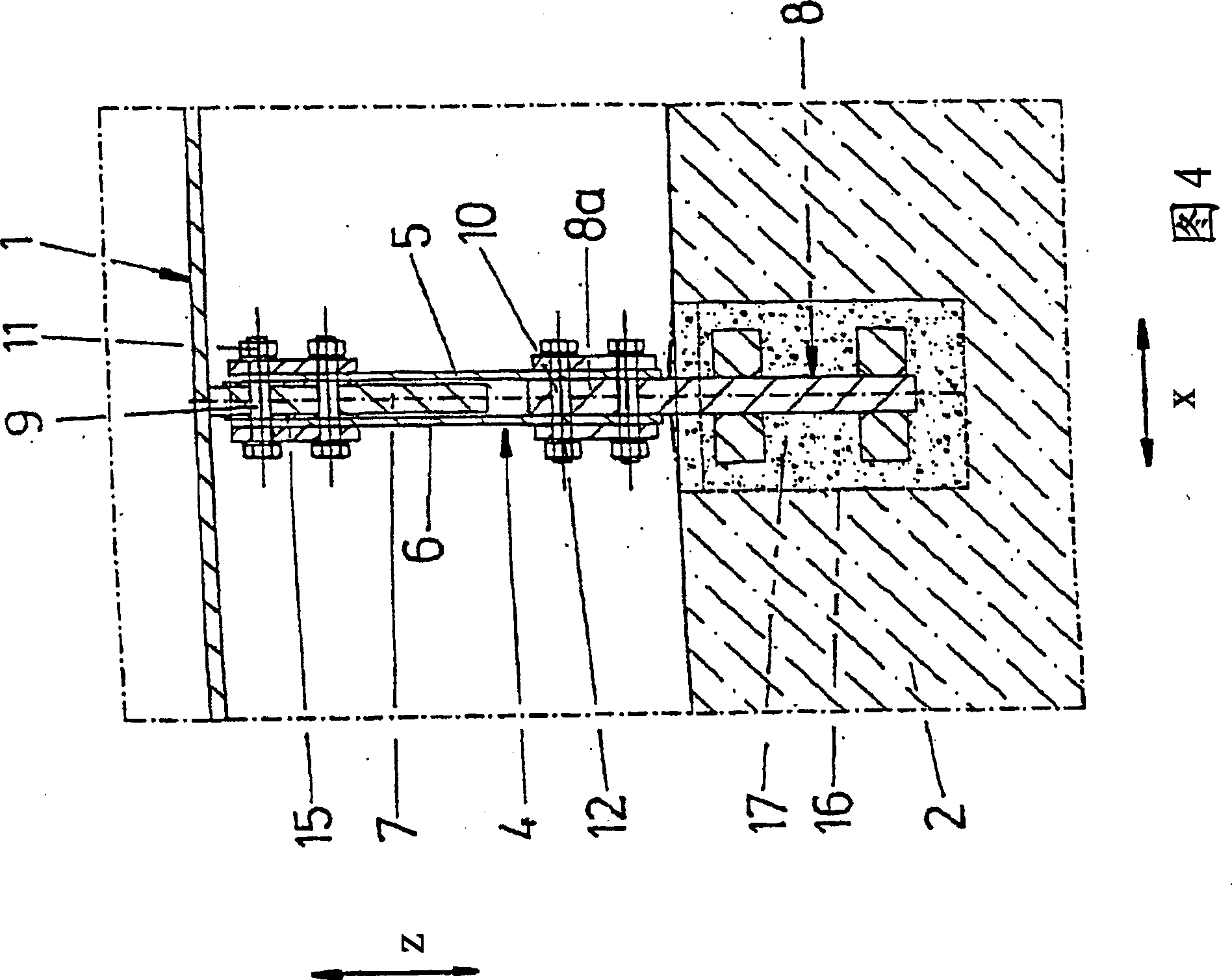

[0014] Figures 1a and 1b schematically show two schemes of a train track of a maglev train. The track comprises a plurality of track modules 1 which are arranged in series in the longitudinal direction (arrow x) and which are provided with various accessories not shown separately, such as stator laminations, side rails, sliding plates, which are necessary for the operation of the maglev train article etc. The length of each module 1 , measured in the x-direction, is eg 6.192 m, while its width, depending on the respective train type, is eg 2.80 m.

[0015] Each module 1 is supported on a main load-bearing structure 2, which involves the respective concrete foundation established on the ground (bottom in FIG. 1 ), a continuous concrete foundation in the x-direction (top in FIG. 1 ) or also for example a trolley A rail truss, itself supported on pillars on the ground or on a foundation established on the ground. For the purposes of the invention, it is in principle irrelevant ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com