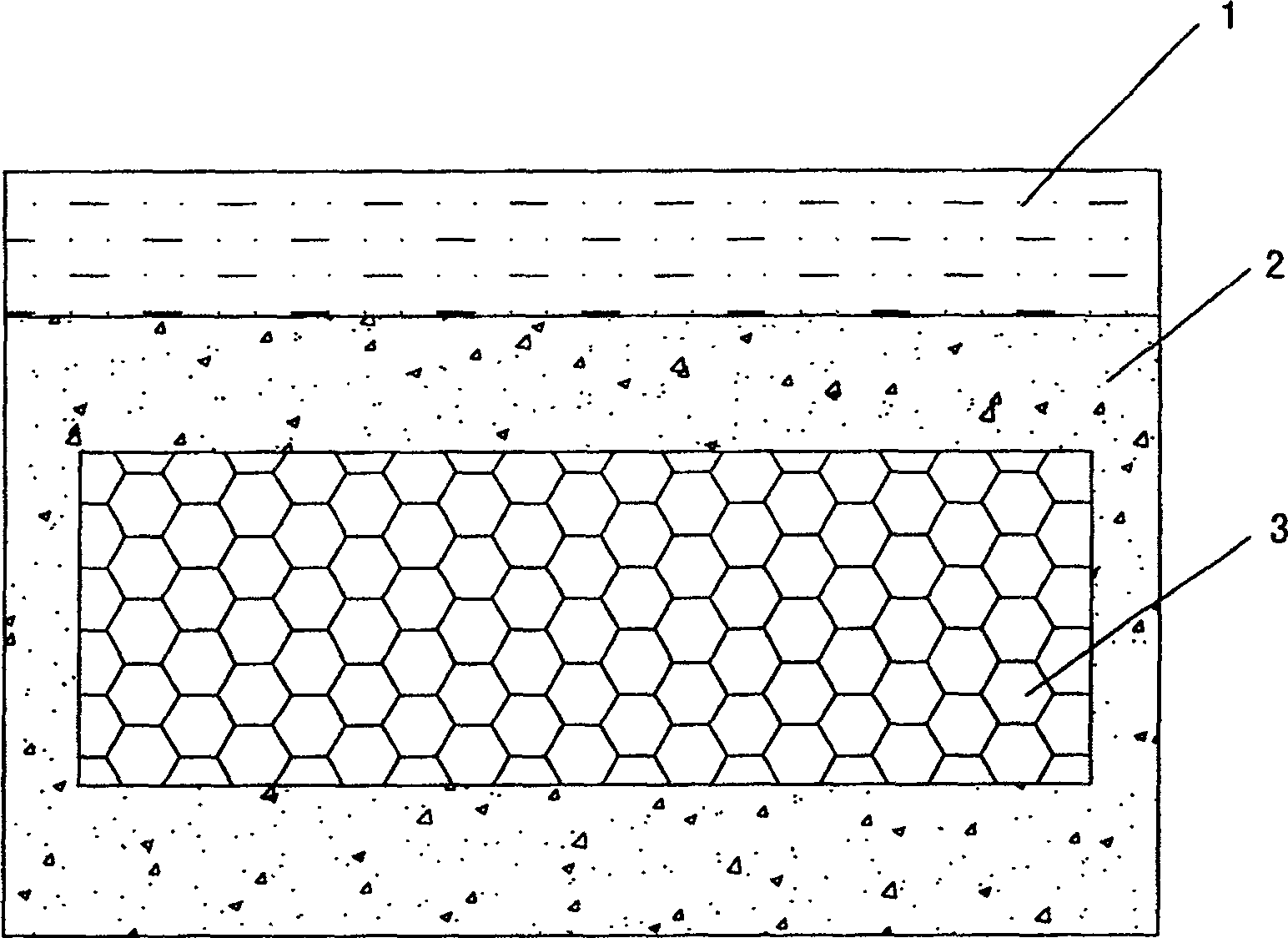

Heat insulation board and its producing method

A manufacturing method and a technology for thermal insulation boards, which are applied in the field of building materials, can solve the problems of high cost, inconvenient manufacturing and construction, and achieve the effects of low cost, light weight and convenient construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

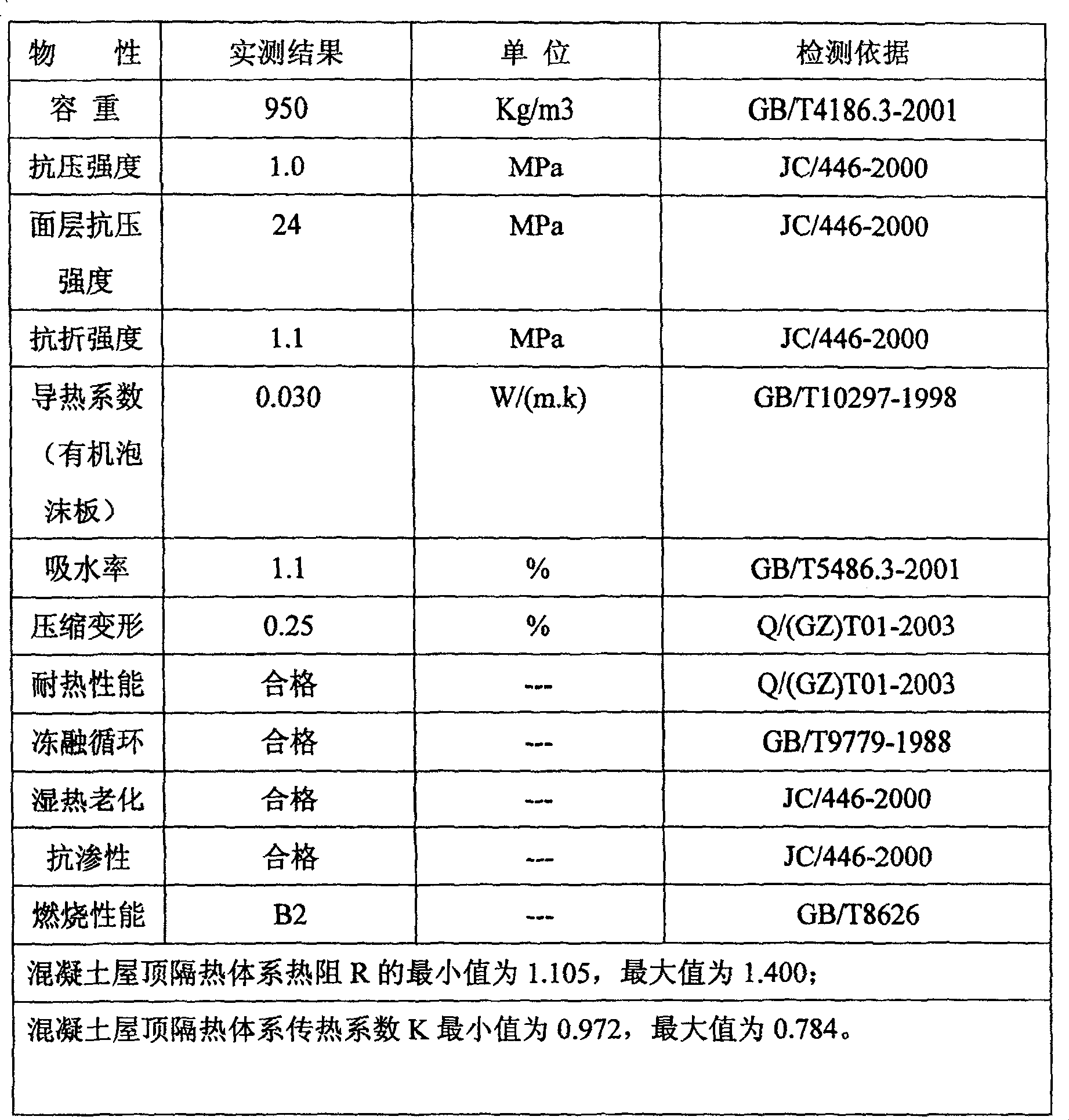

Examples

Embodiment 1

[0039] Apply the binder emulsion on the surface of the organic foam board 3 first, and let it dry naturally for 60-120 minutes; the formula of the binder emulsion is 1Kg of binder and 2.5Kg of water. The binder is an acrylate polymer.

[0040] Use a release agent to coat the inner surface of the insulation board mold; the release agent can be sodium silicate precipitation or sodium phosphate, and the most commonly used is waste engine oil.

[0041] Make wear-resistant cement slurry according to the following formula:

[0042] Toner 8Kg, white cement 300Kg, binder emulsion 15Kg, binder is acrylic ester polymer, defoamer 2Kg, defoamer is tributyl phosphate.

[0043] Pour the toner and white cement of the above components into a mixer and stir evenly, then pour in the binder emulsion and defoamer for stirring to form a cement slurry. Pour the prepared wear-resistant cement slurry into a mold suitable for the external dimensions of the insulation board to make the cement wear-re...

Embodiment 2

[0049] Make wear-resistant cement slurry according to the following formula:

[0050] Color powder 20Kg, white cement 400Kg, binder emulsion 30Kg, defoamer 5Kg.

[0051] Make the mixture as follows:

[0052] 650Kg of cement, 300Kg of quartz sand, 80Kg of lightweight hollow powder, 30Kg of binder, 8Kg of foaming agent, and 200Kg of water.

[0053] Others are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com