Circuit board air-pumping ink-penetrating hole-filling method and device thereof

An air extraction device and circuit board technology, which is applied in the manufacturing of electrical components, printed circuits, and multi-layer circuits, can solve the problems of covering electroplating structure depression, insufficient depth of ink filling holes, and poor production process yield, etc. The effect of ink sag difference and improving the yield of the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

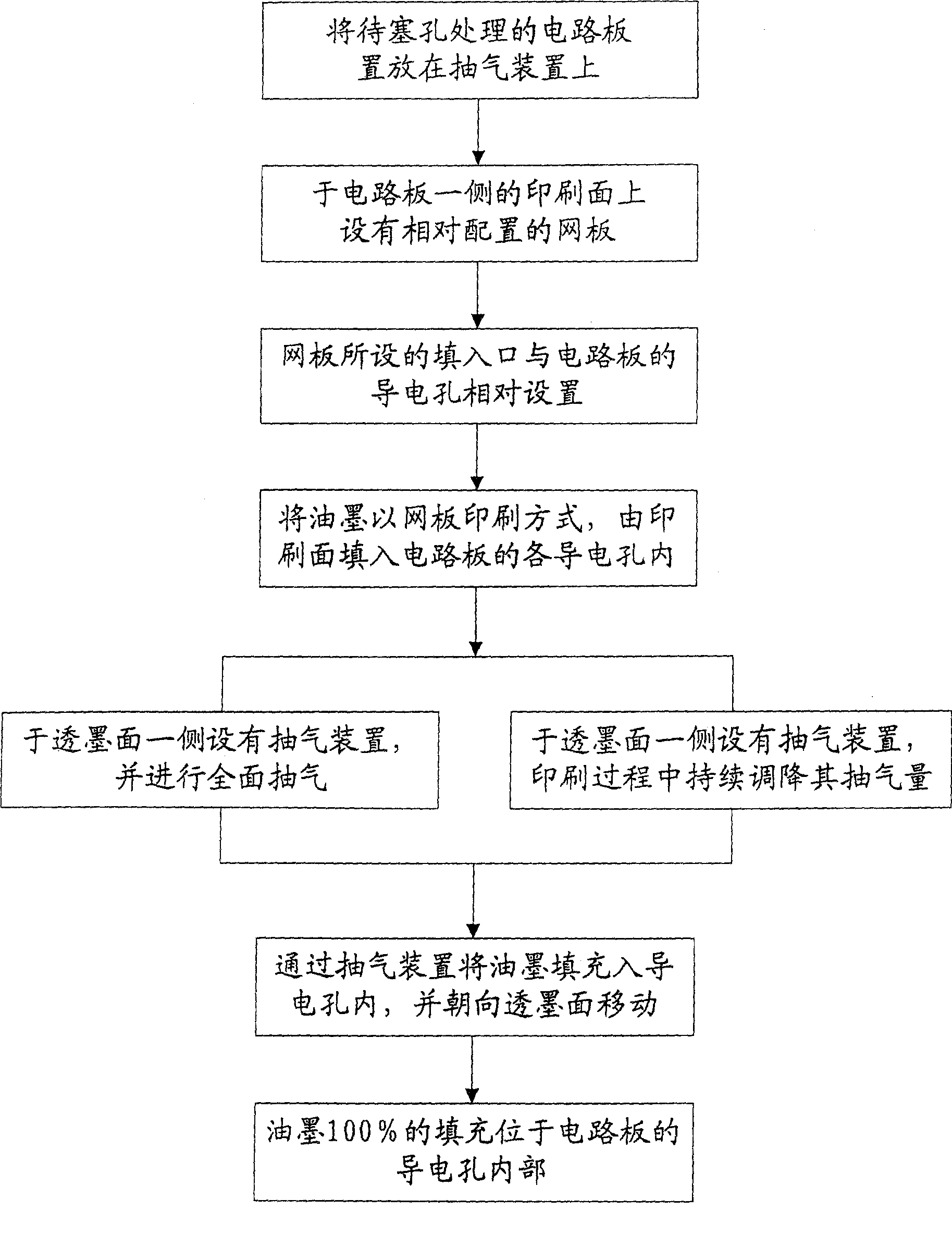

[0032] see figure 1 Shown, the circuit board air extraction method that the present invention proposes through ink plug hole, its method mainly contains:

[0033] a. Place the circuit board to be plugged on the air extraction device;

[0034] b. Set a stencil (or steel plate) on the printing surface opposite to the circuit board side;

[0035] c. The filling port set by the screen plate is set opposite to the conductive hole of the circuit board;

[0036] d. Then move the ink on the screen with a scraper, and the ink can enter the hole from the filling port through the conductive hole on the side of the printing surface;

[0037] e. After the suction device on the ink-permeable surface of the other side of the circuit board is activated, the ink in the printing surface and the conductive hole can be moved towards the ink-permeable surface to complete filling.

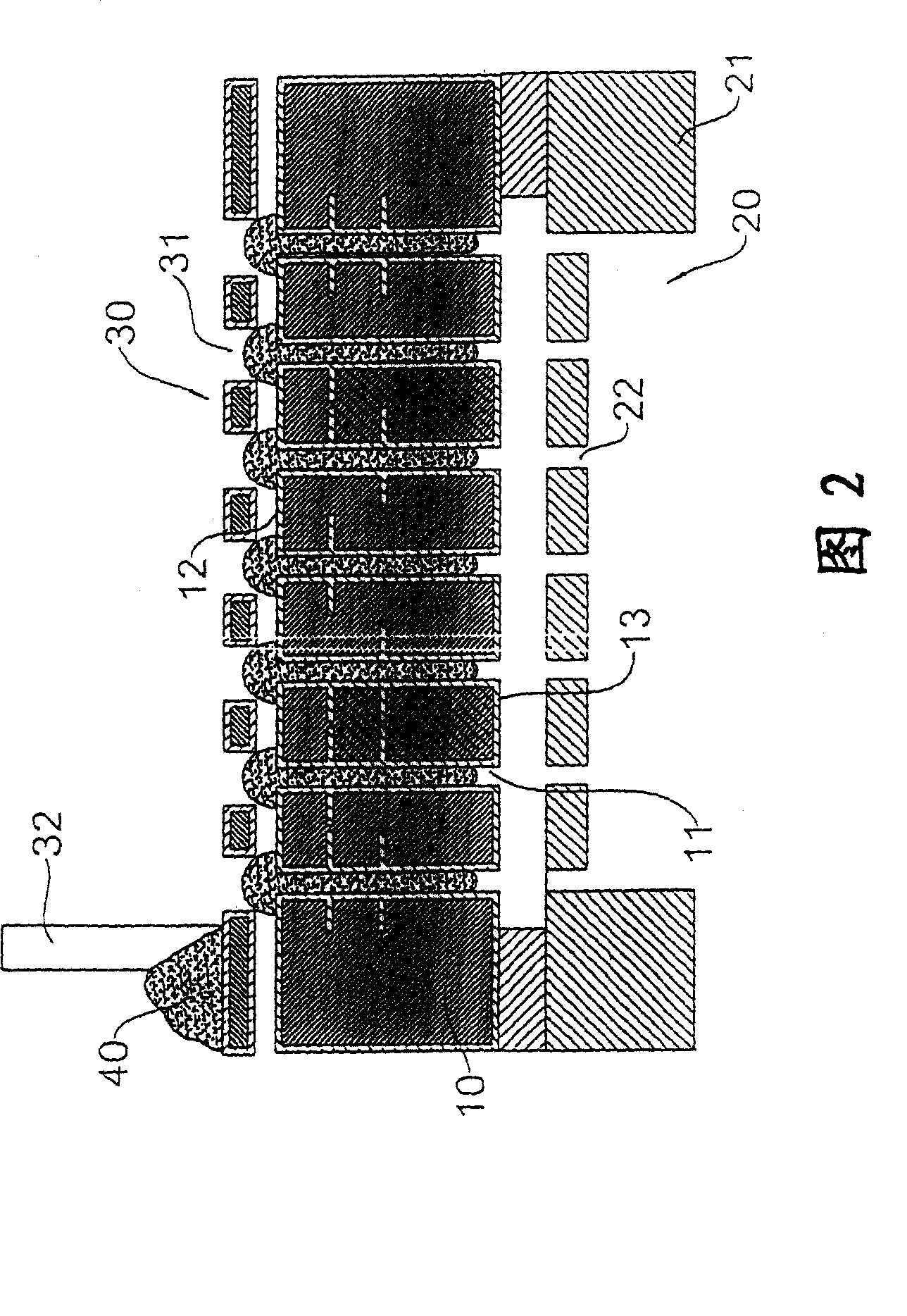

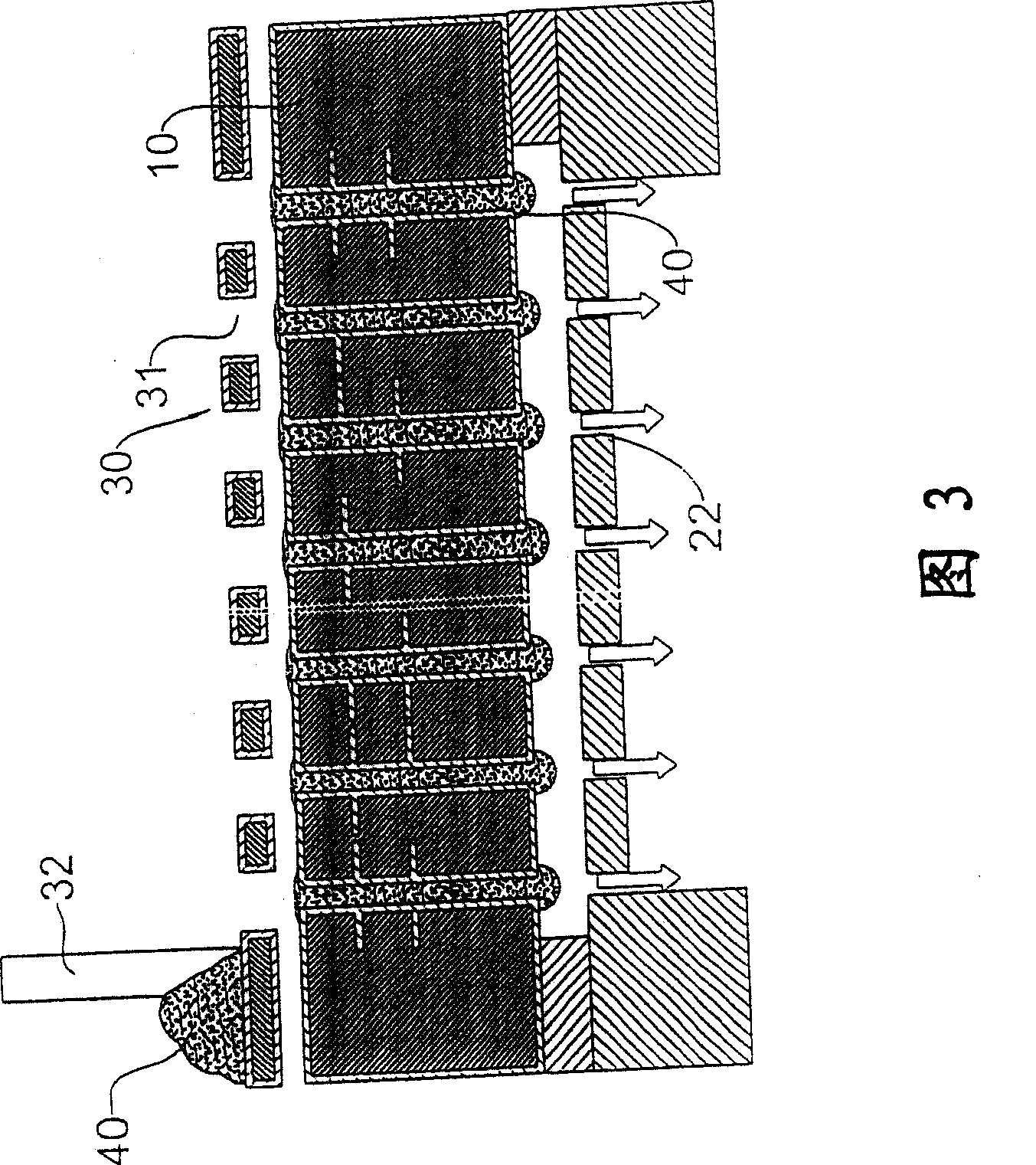

[0038] For the specific implementation method of the present invention, please refer to Fig. 2 and shown in Fig. 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com