Method for preparing monodisperse ternary sulfide CuInS2

A ternary sulfide, monodisperse technology, applied in chemical instruments and methods, copper sulfide, gallium/indium/thallium compounds, etc., can solve the cumbersome synthesis process of single-molecule precursors, highly toxic precursors, high production costs, etc. problem, to achieve the effect of low cost, cheap raw material and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] ①In a 100ml flask, add 0.4mmol of copper acetate, 0.4mmol of indium chloride, and 4mmol of octadecylamine into 39ml of anisole, heat to 60°C and keep it for 1 hour, then add 0.5ml of carbon disulfide, Continue magnetic stirring while adding to prepare CuInS 2 Reaction solution of nanocrystals.

[0019] ②Put the reaction solution prepared according to step ① into a high-pressure reactor with a 50ml polytetrafluoroethylene liner. After reacting at 200°C for 12 hours, the reactor is naturally cooled to 60°C, and 10ml of methanol is added. After centrifugation, use After washing several times with absolute ethanol and vacuum drying the sample, the monodisperse ternary sulfide CuInS can be obtained 2 Nanocrystalline.

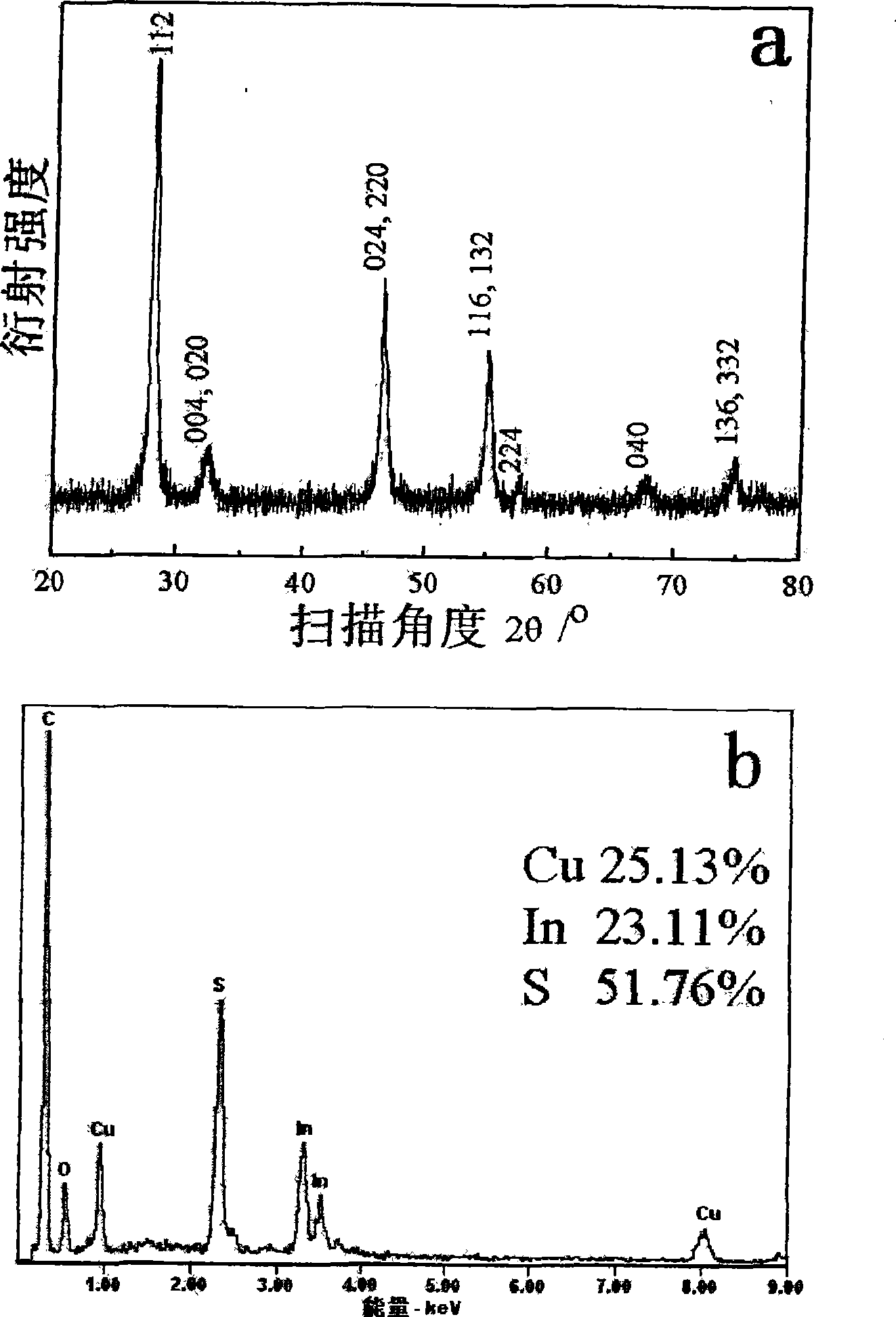

[0020] The resulting monodisperse ternary sulfide CuInS 2 The X-ray diffraction pattern of nanocrystals is shown in figure 1 a. It can be seen from the figure that the prepared material is tetragonal CuInS 2 . figure 1 b is to get CuInS 2 The energy sc...

Embodiment 2

[0022] ①In a 100ml flask, add 0.4mmol of copper acetate, 0.4mmol of indium chloride, and 3.6mmol of hexadecylamine into 39ml of anisole, heat to 60°C and keep it for 1 hour, then add 1ml of carbon disulfide, Continue magnetic stirring while adding to prepare CuInS 2 Reaction solution of nanocrystals.

[0023] ②Put the reaction solution prepared according to step ① into a high-pressure reactor with a 50ml polytetrafluoroethylene liner. After solvent heating at 200°C for 24 hours, the reactor is naturally cooled to 60°C, and 10ml of methanol is added. After centrifugation, Wash several times with absolute ethanol, and vacuum-dry the sample to obtain the monodisperse ternary sulfide CuInS similar to Example 1. 2 Nanocrystalline.

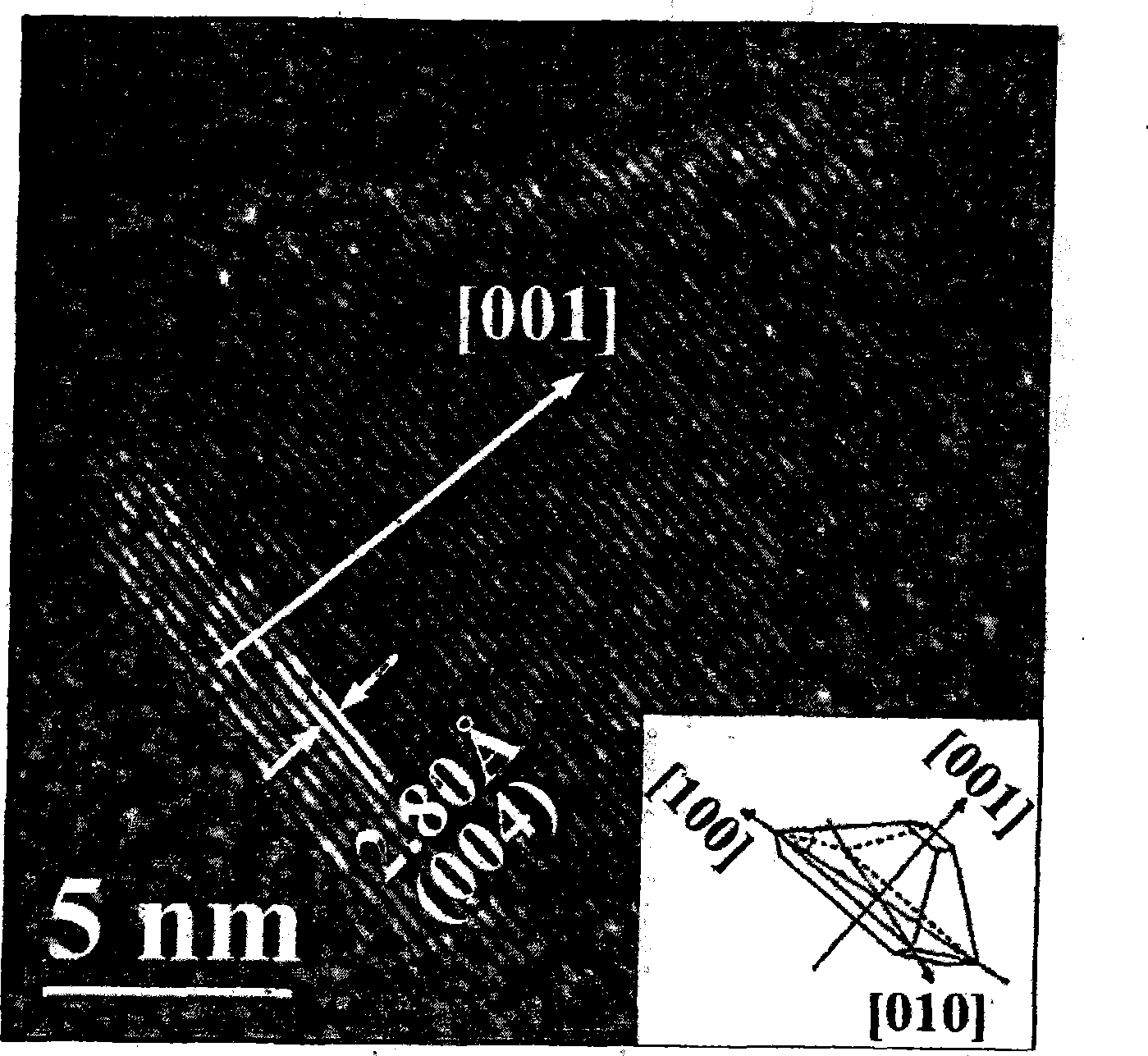

[0024] image 3 is the resulting ternary sulfide CuInS 2 High-resolution TEM images of nanocrystals. It can be seen from the figure that the ternary sulfide CuInS 2 The nanocrystals have clear lattice fringes, illustrating that the as-synthesized ...

Embodiment 3

[0026] ①In a 100ml flask, add 0.8mmol of copper acetate, 0.8mmol of indium chloride, and 12mmol of oleylamine into 39ml of anisole, heat to 60°C and keep it for 1 hour, add 0.5ml of carbon disulfide, add While continuing the magnetic stirring, the preparation of CuInS 2 Reaction solution of nanocrystals.

[0027] ②Put the reaction solution prepared according to step ① into a high-pressure reactor with a 50ml polytetrafluoroethylene liner. After solvent heating at 200°C for 24 hours, the reactor is naturally cooled to 60°C, and 10ml of methanol is added. After centrifugation, Wash the sample several times with absolute ethanol and vacuum dry the sample to obtain the monodisperse ternary sulfide CuInS2 Nanocrystalline.

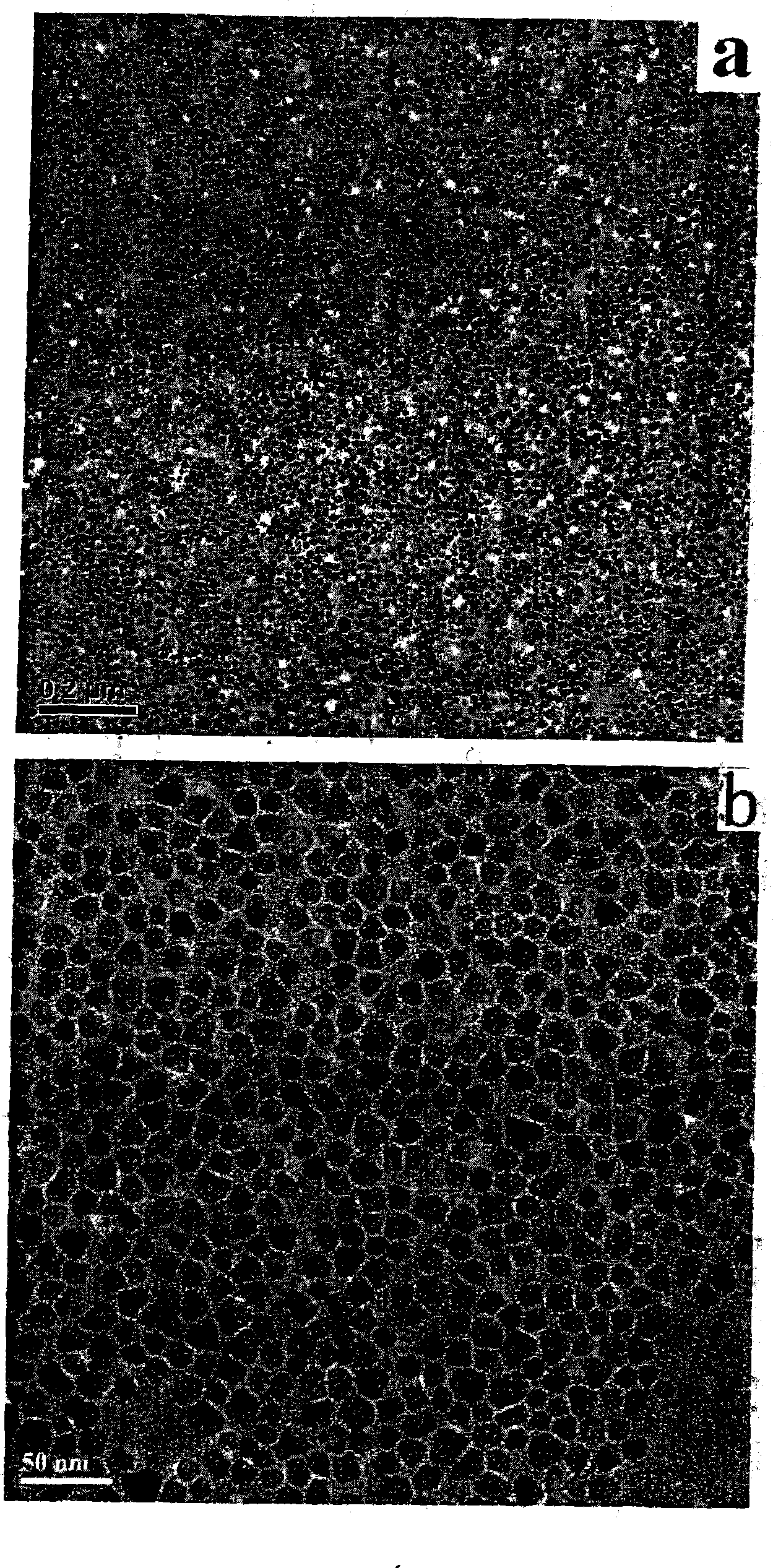

[0028] Figure 4 is the obtained monodisperse ternary sulfide CuInS 2 TEM image of nanocrystals. It can be seen from the figure that the morphology and size of the product of this example are almost the same as those of Example 1, and can self-assemble into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com