Micro-connector and its terminal shape production method

A micro-connector and connector technology, which is applied to the parts of the connection device, the device for connecting, engaging/disconnecting the connected parts, etc., can solve the problems of test time and cost waste, terminal wear, high insertion force, etc., and achieve The effect of saving test time and cost, reducing the size of the device, and reducing the overall size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

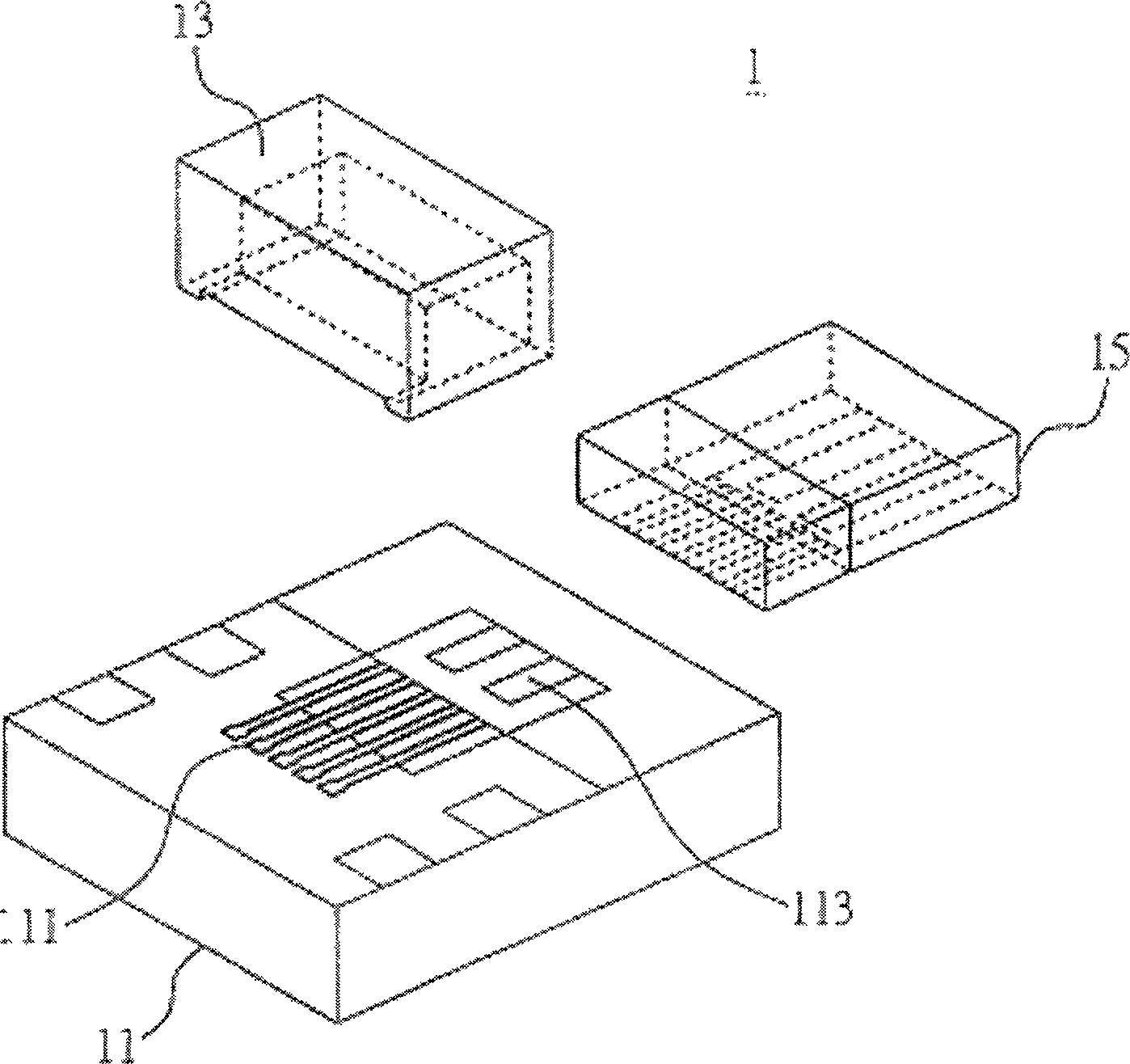

[0045] Figures 1 to 11C It is drawn according to Embodiment 1 of the manufacturing method of the miniature connector and its terminal shape of the present invention. Such as figure 1 As shown, the micro connector 1 includes a base 11 , a cover 13 and an insert 15 .

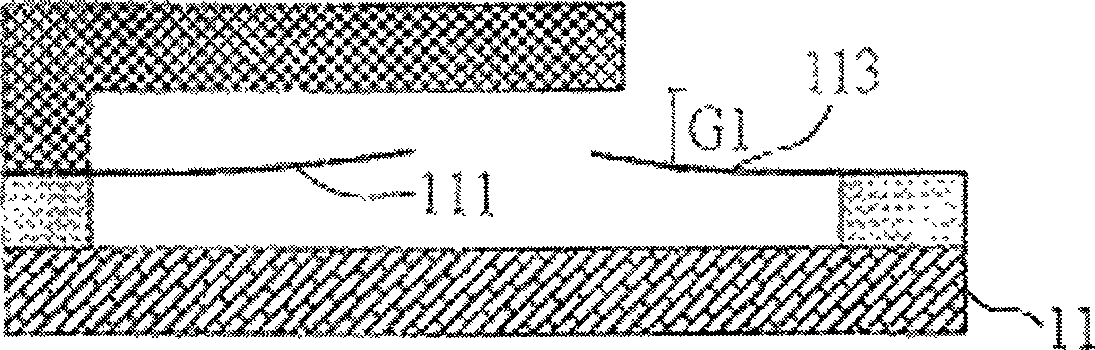

[0046] The base 11 has a first conductive connection portion 111 and a barb portion 113 . In the first embodiment, the base 11 can be made of materials such as silicon, and the first conductive connection part 111 can be composed of a plurality of female terminals, and the barb part 113 can be, for example, a shrapnel, and make the first conductive The end of the connecting portion 111 and the barb portion 113 is an arc structure bent upwards. The method of forming the first conductive connection portion 111 and the barb portion 113 on the base 11 will be described in detail later.

[0047] Such as figure 2 As shown, the cover 13 is arranged on the base 11, and forms a gap G1 (first gap) with the first cond...

Embodiment 2

[0059] Figure 12 It is drawn according to Embodiment 2 of the present invention. Wherein, components identical or similar to those in Embodiment 1 above are represented by identical or similar component symbols, and detailed descriptions are omitted to make the description of this case clearer and easier to understand.

[0060] Different from the first embodiment above, the cover 13 of this embodiment forms a chamfer 137 on the edge of the third recess 135 corresponding to the gap G1, making it easier for the insert 15 to be inserted into the cover 13 and the base 11 between. Certainly, those skilled in the art know that the size of the chamfer 137 is not limited to that described in this embodiment. In this way, the insertion force can be further reduced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com