Rolling device

A rolling mill frame, work roll technology, applied in the direction of metal rolling, metal rolling, counter pressure devices, etc., can solve the problems of damaged bearings, guide work roll bearing housings, can not be guaranteed, etc., to avoid tilting, compact The effect of structural form

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

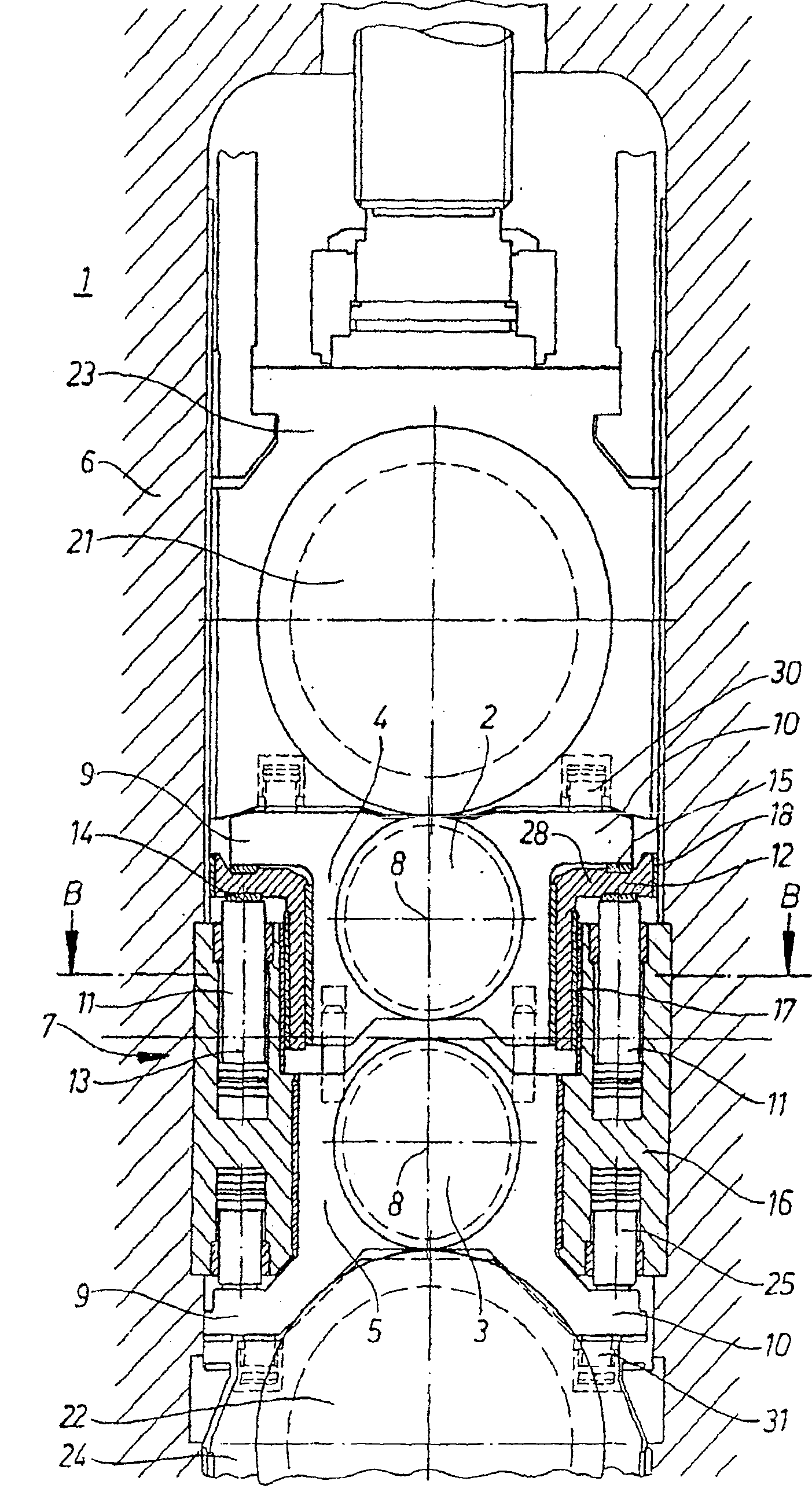

[0039] in figure 1 3 shows a rolling device 1 in which two cooperating work rolls 2 and 3 are arranged in a rolling mill stand 6, and the work rolls are supported in a work roll chock 4 or 5, respectively.

[0040] In order to arbitrarily adjust the roll gap between the two work rolls 2 and 3 to a large extent, the upper work roll chock 4 can be adjusted in the vertical direction; that is, it can be relative to the rolling mill stand 6 in the vertical direction. mobile.

[0041] The work rolls 2 and 3 are respectively supported on a supporting roll 21 or 22, wherein these supporting rolls are supported in a supporting roll chock 23 or 24, respectively. The rolling device 1 has a total of four rolls. It should be noted that it can also have other rolls, namely intermediate rolls arranged between the work rolls 2, 3 and the support rolls 21, 22.

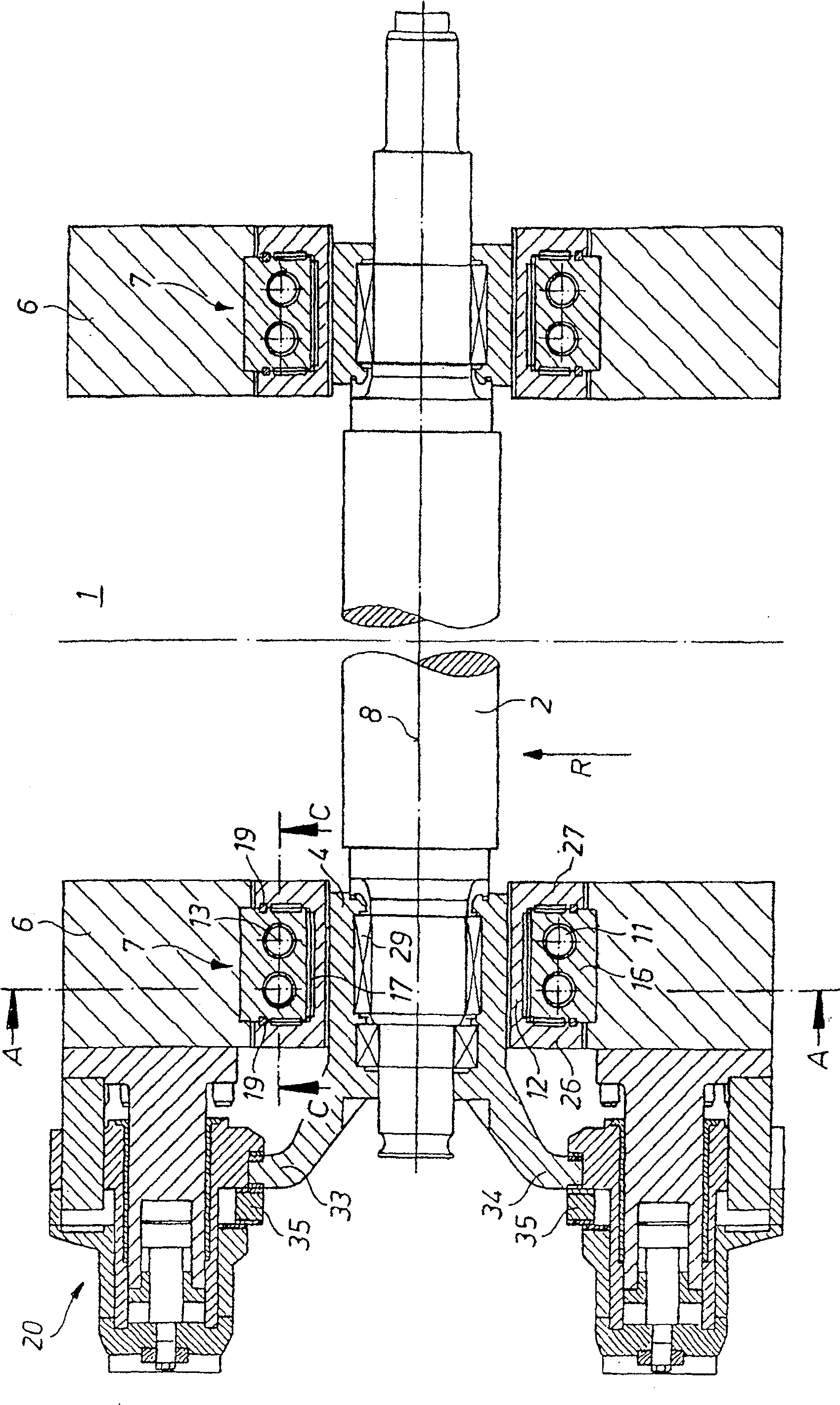

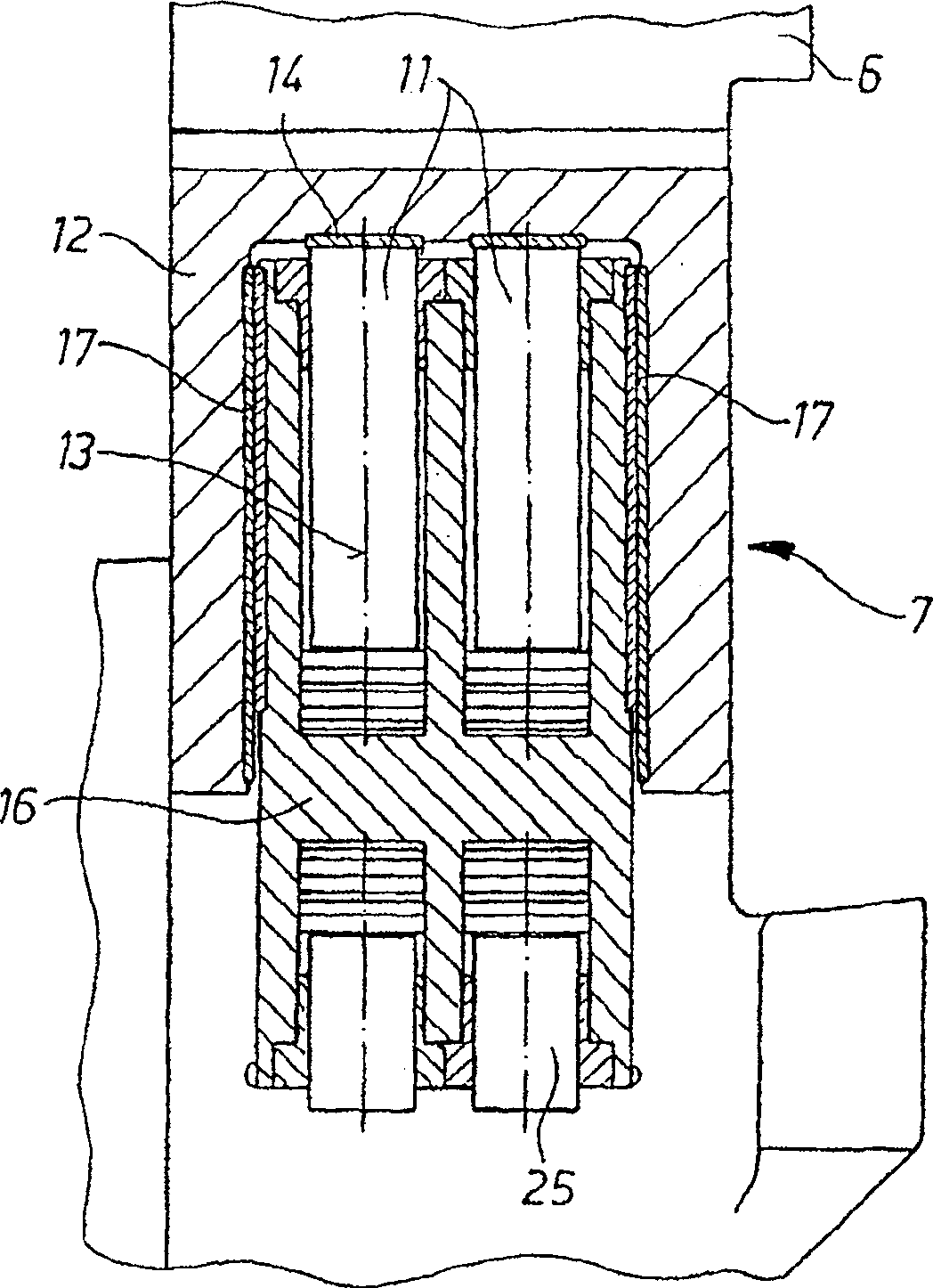

[0042] In order to introduce the bending moment to the work rolls 2 and 3, a bending mechanism 7 is provided. As especially by figure 2 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap