Supporting roller split inner sleeve or split bearing assembled connecting device

A technology for coupling devices and support rollers, applied in the direction of shafts and bearings, can solve problems such as difficult disassembly, affect the quality of finished products, and poor dustproof performance, and achieve the advantages of increased assembly strength and assembly speed, wide application range, and improved assembly accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

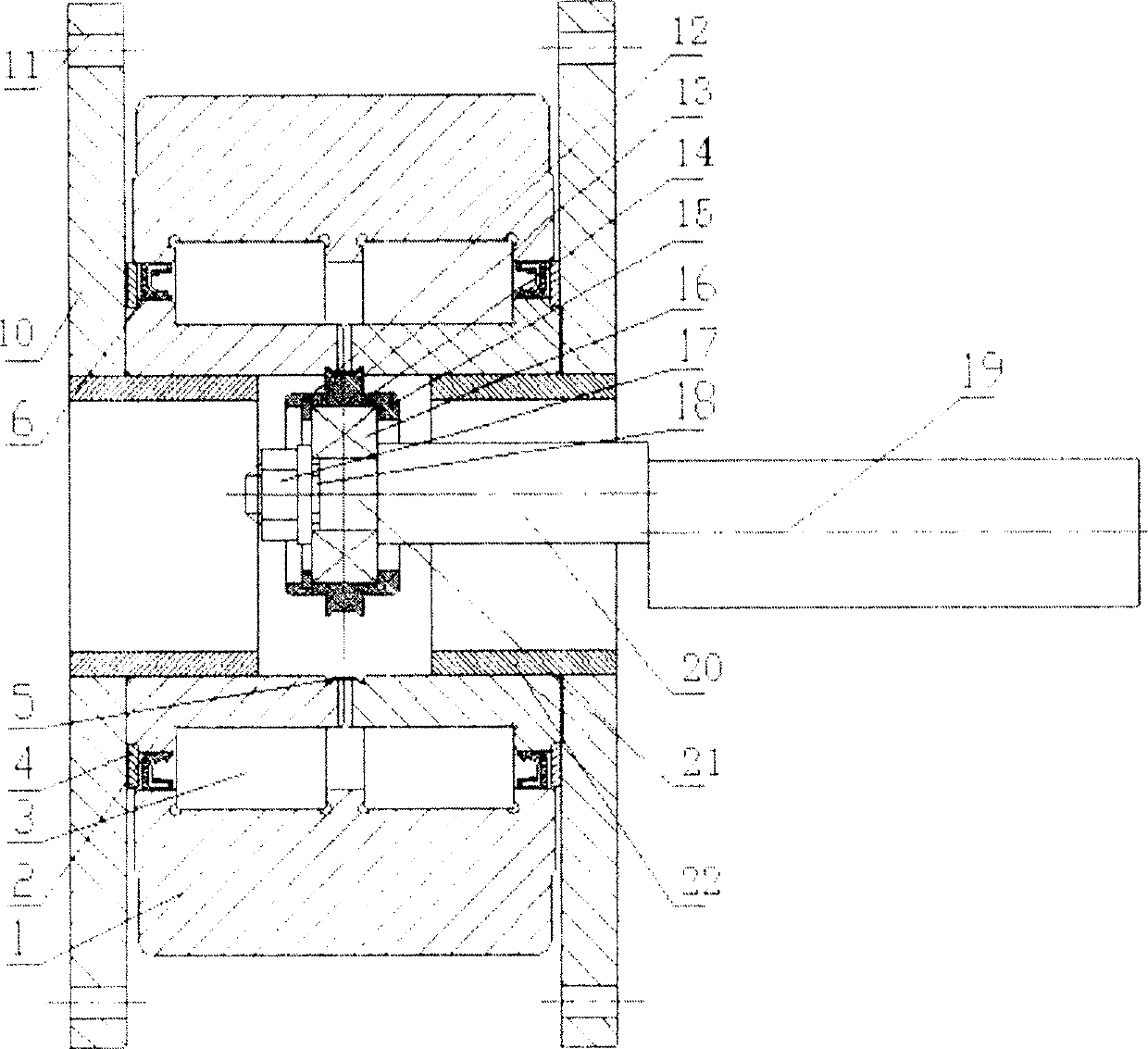

[0021] see image 3 In this embodiment, the assembly and connection device of the split inner sleeve of the support roller includes a clamping end cover 10, a snap ring 12, a molding convex ring 13, an inner ring of the molding ring 14, a positioning ring 15, a bearing 16, a fastening nut and a gasket 17, Install the screw rod 18, the eccentric clamping handle 19, the transition cylinder 20, the bearing block 21, and the positioning inner sleeve 22.

[0022] see image 3 , The present embodiment is composed of two parts, the clamping of the backup roller and the connection molding. One part can be selected to rotate at a fixed axis, and the other part can be fixed, so that the molding connection of the inner ring of the backup roller can be realized.

[0023] see also Figure 4 , Figure 8 , the clamping part of the backup roller is welded to the inner hole of the clamping end cover 10 by the positioning inner sleeve 22 (it can also be processed as a whole), and the two end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com