Capacity adjustable vortex compressor refrigeration system with mediate loop installed with ejector

A technology of scroll compressors and intermediate circuits, which is applied in the direction of irreversible cycle compressors, compressors, refrigerators, etc., to achieve the effects of improving adaptability, improving thermodynamic perfection, and reducing irreversible losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

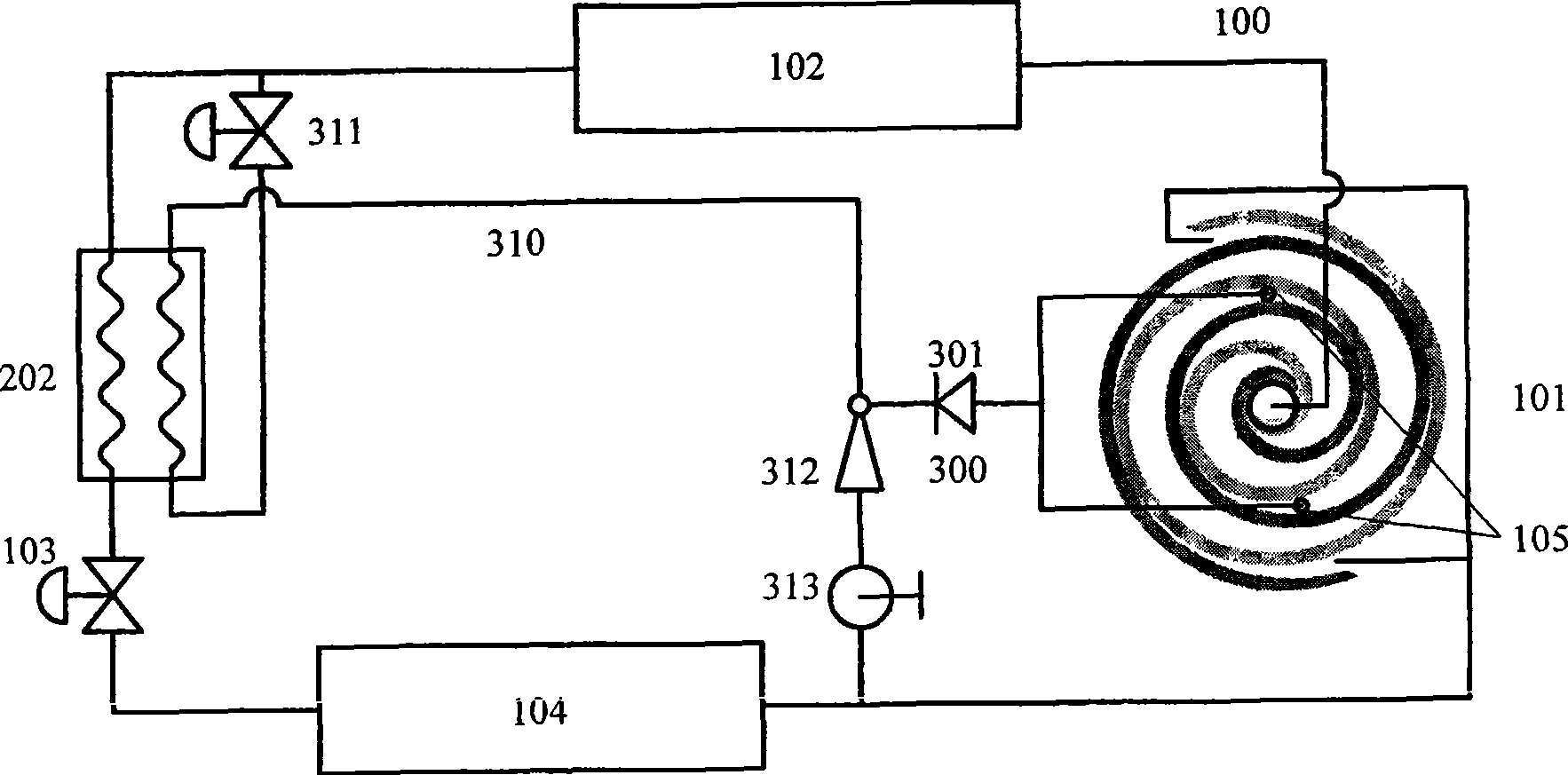

Embodiment 1

[0027] figure 1 It is a structural schematic diagram of a scroll compressor refrigeration system using an ejector and an intermediate heat exchanger for refrigerant leakage. The system includes a refrigerant primary circuit 100 and a refrigerant escape system. The main refrigerant circuit 100 is composed of a scroll compressor 101 with a refrigerant discharge port 105 , a condenser 102 , a system expansion device 103 and an evaporator 104 connected in sequence. The refrigerant leakage system includes an intermediate heat exchanger 202, a refrigerant leakage working circuit 310 and a refrigerant refrigeration leakage injection circuit 300, wherein the intermediate heat exchanger 202 is arranged on the main refrigerant circuit 100 of the system from the condenser 102 to On the pipeline between the system expansion devices 103, one end of the refrigerant discharge working circuit 310 is connected to the outlet pipeline of the condenser 102, and the other end sequentially passes ...

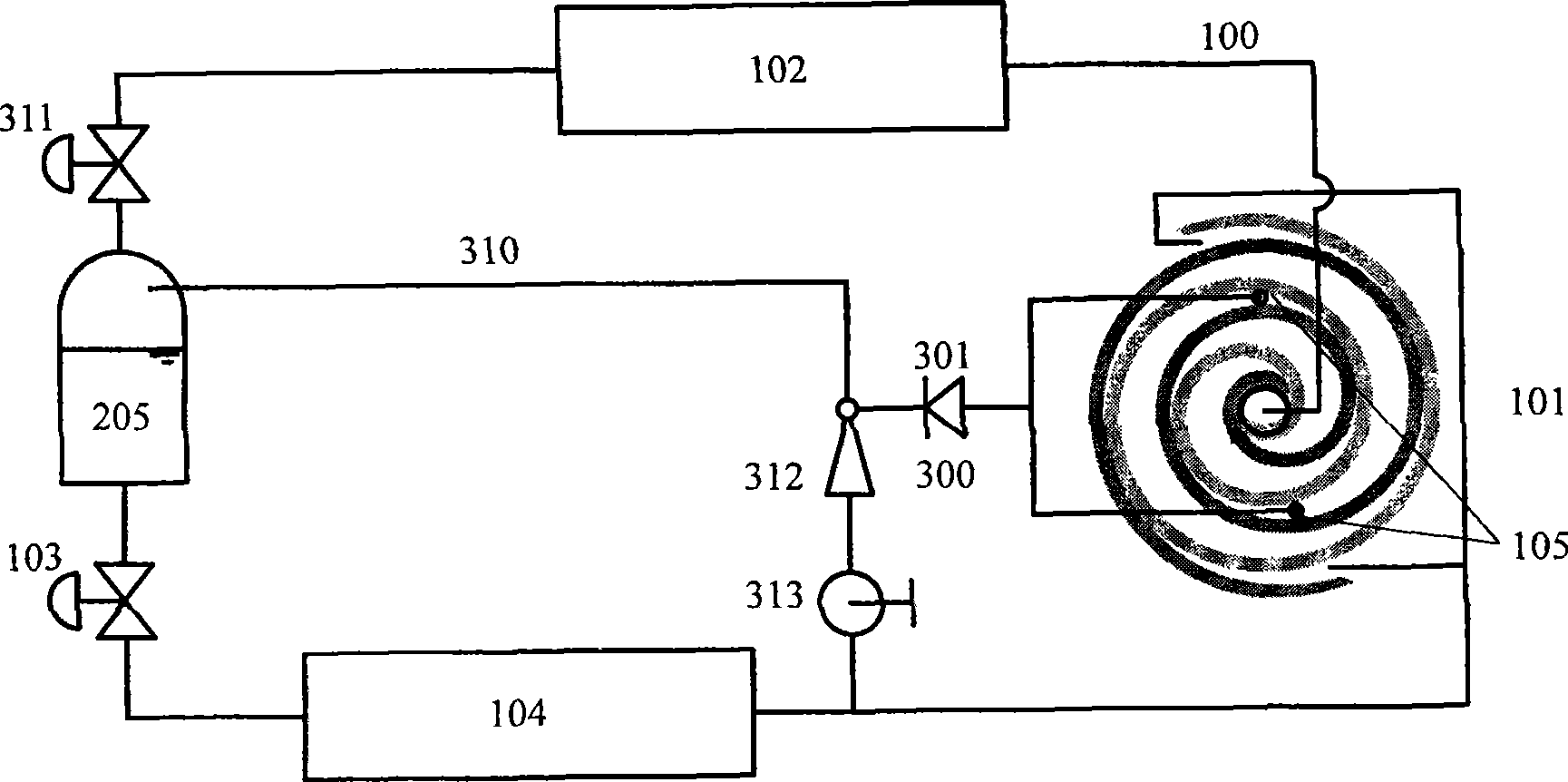

Embodiment 2

[0031] figure 2 It is a structural schematic diagram of a scroll compressor refrigeration system using an ejector and a flash tank for refrigerant discharge. The system includes a refrigerant primary circuit 100 and a refrigerant escape system. The main refrigerant circuit 100 is composed of a scroll compressor 101 with a refrigerant discharge port 105 , a condenser 102 , a system expansion device 103 and an evaporator 104 connected in sequence. The refrigerant discharge system includes a discharge expansion device 311, a flash tank 205, a refrigerant discharge working circuit 310 and a refrigerant refrigeration discharge injection circuit 300, wherein the discharge expansion device 311 and the flash tank 205 are sequentially arranged in On the pipeline from the outlet of the condenser 102 to the inlet of the system expansion device 103 on the main refrigerant circuit 100 of the system, one end of the refrigerant discharge working circuit 310 is connected to the flash tank 2...

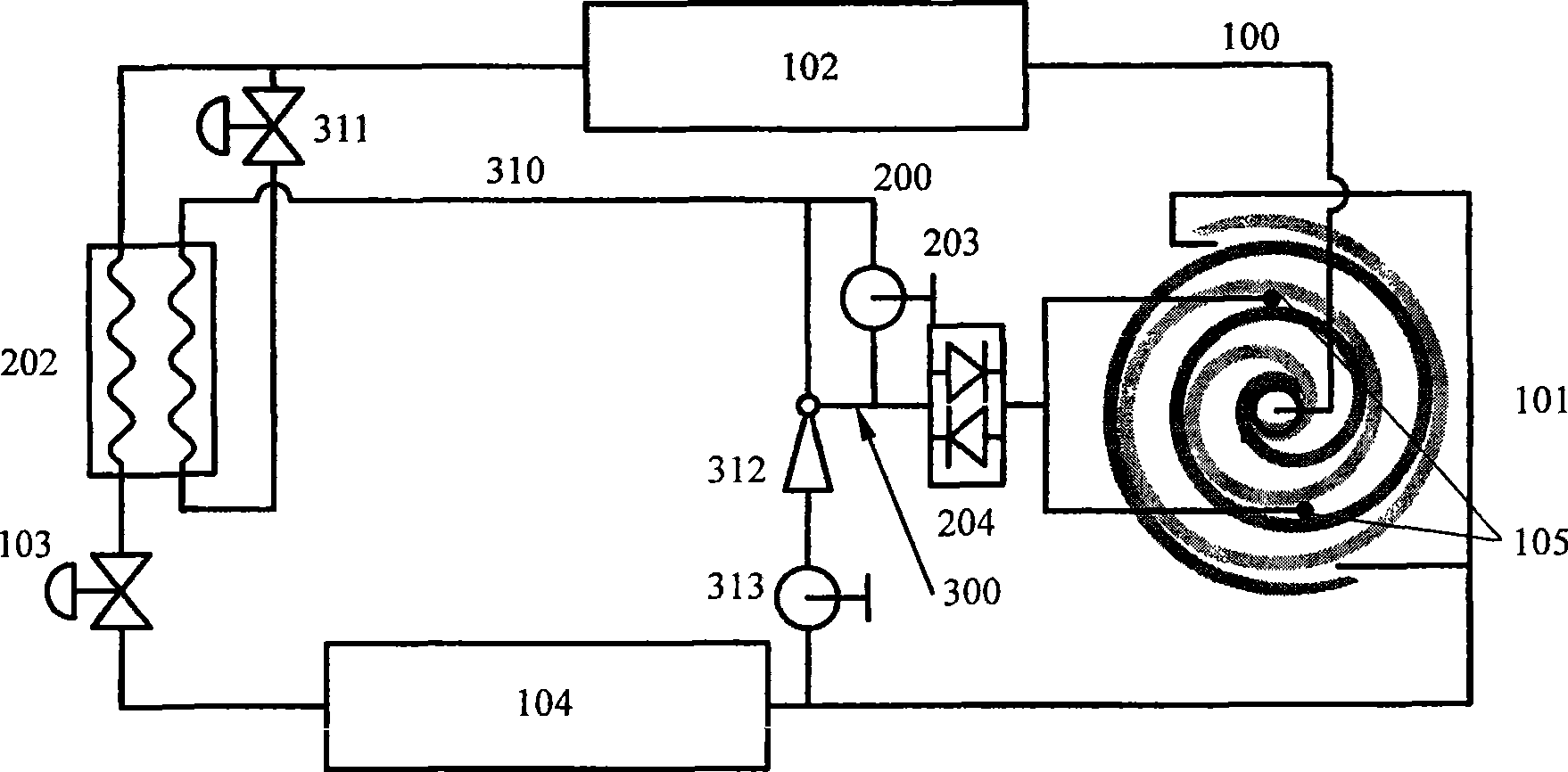

Embodiment 3

[0035] image 3It is a structural schematic diagram of a scroll compressor refrigeration system using an ejector and an intermediate heat exchanger for refrigerant discharge and injection. The system includes a refrigerant main circuit 100 , a refrigerant discharge system and a refrigerant injection circuit 200 . The main refrigerant circuit 100 is composed of a scroll compressor 101 with a refrigerant discharge port 105 , a condenser 102 , a system expansion device 103 and an evaporator 104 connected in sequence. The refrigerant leakage system includes an intermediate heat exchanger 202, a refrigerant leakage working circuit 310 and a refrigerant refrigeration leakage injection circuit 300, wherein the intermediate heat exchanger 202 is arranged on the main refrigerant circuit 100 of the system from the condenser 102 to On the pipeline between the system expansion devices 103, one end of the refrigerant discharge working circuit 310 is connected to the outlet pipeline of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com