Sail wing for increasing lift force and stalling attack angle

A technology for stalling angle of attack and increasing lift, applied in the field of aviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

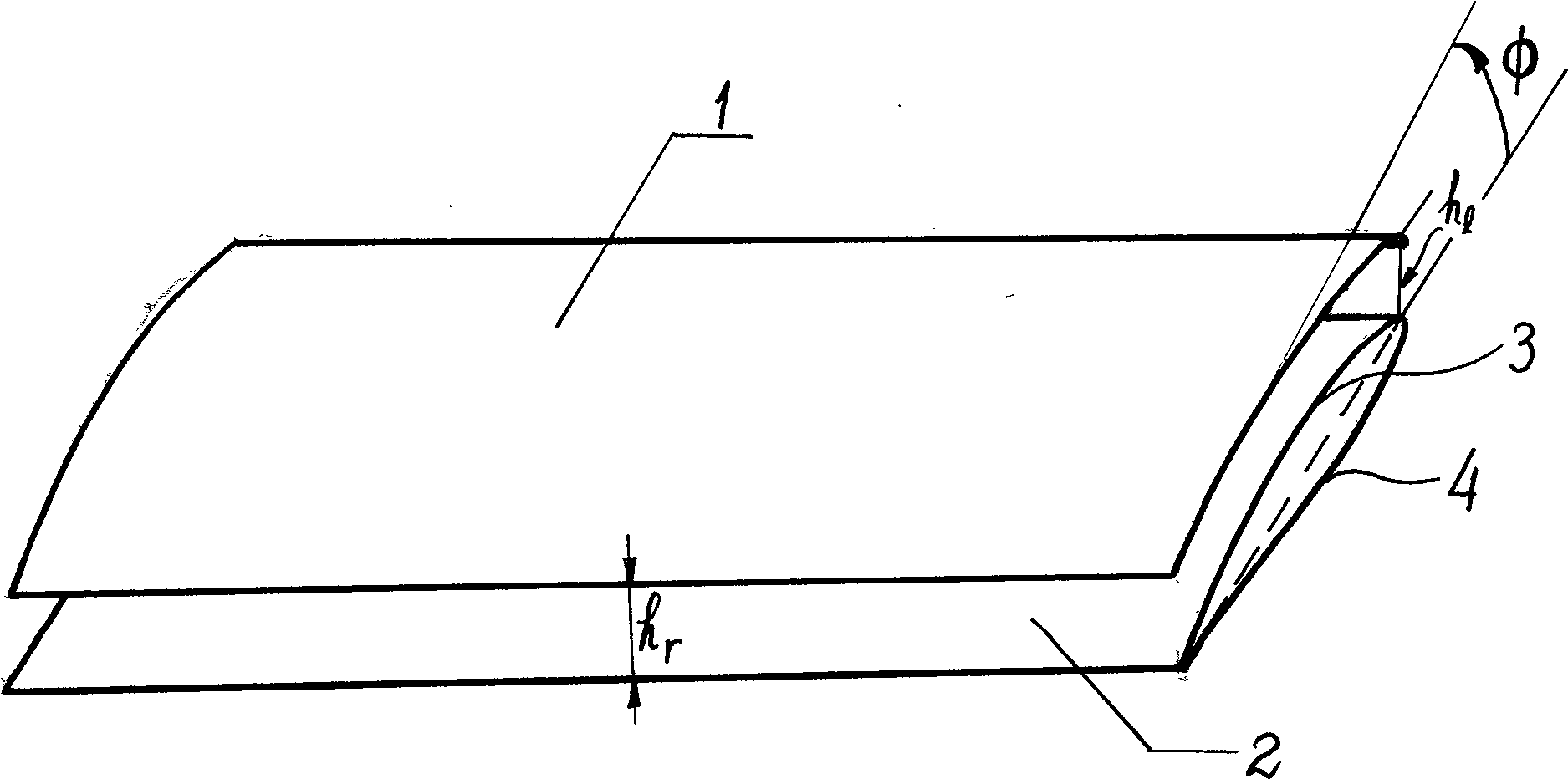

[0013] Depend on figure 1 It can be seen that the awning wing 1 is located above the upper airfoil surface 3 of the wing 2 . The leading edge and trailing edge of the awning wing and wing are parallel to each other along the span direction, but along the chord direction, the distance between the lower surface of the awning wing and the upper surface of the wing is not necessarily equal. h r is the relative height of the canopy to the trailing edge of the wing. h 1 is the relative height of the canopy to the leading edge of the wing. When H r =H 1 , the upper surface 3 of the awning wing 1 and the wing is parallel to each other. When H r ≠ H 1 , the canopy wing has an installation angle Φ relative to the wing. The Φ angle is the angle between the line connecting the front and rear edges of the canopy and the wing chord. Φ is changed (usually positive) by changing H 1 (fixed H r ) to achieve. h 1 The size will affect the lifting effect of this device. Through calc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com