Special airfoil for blade tip of wind driven generator

A wind turbine and airfoil technology, applied in the field of wind turbine components, can solve the problems of the influence of the aerodynamic performance of the airfoil leading edge roughness, the small maximum lift coefficient and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

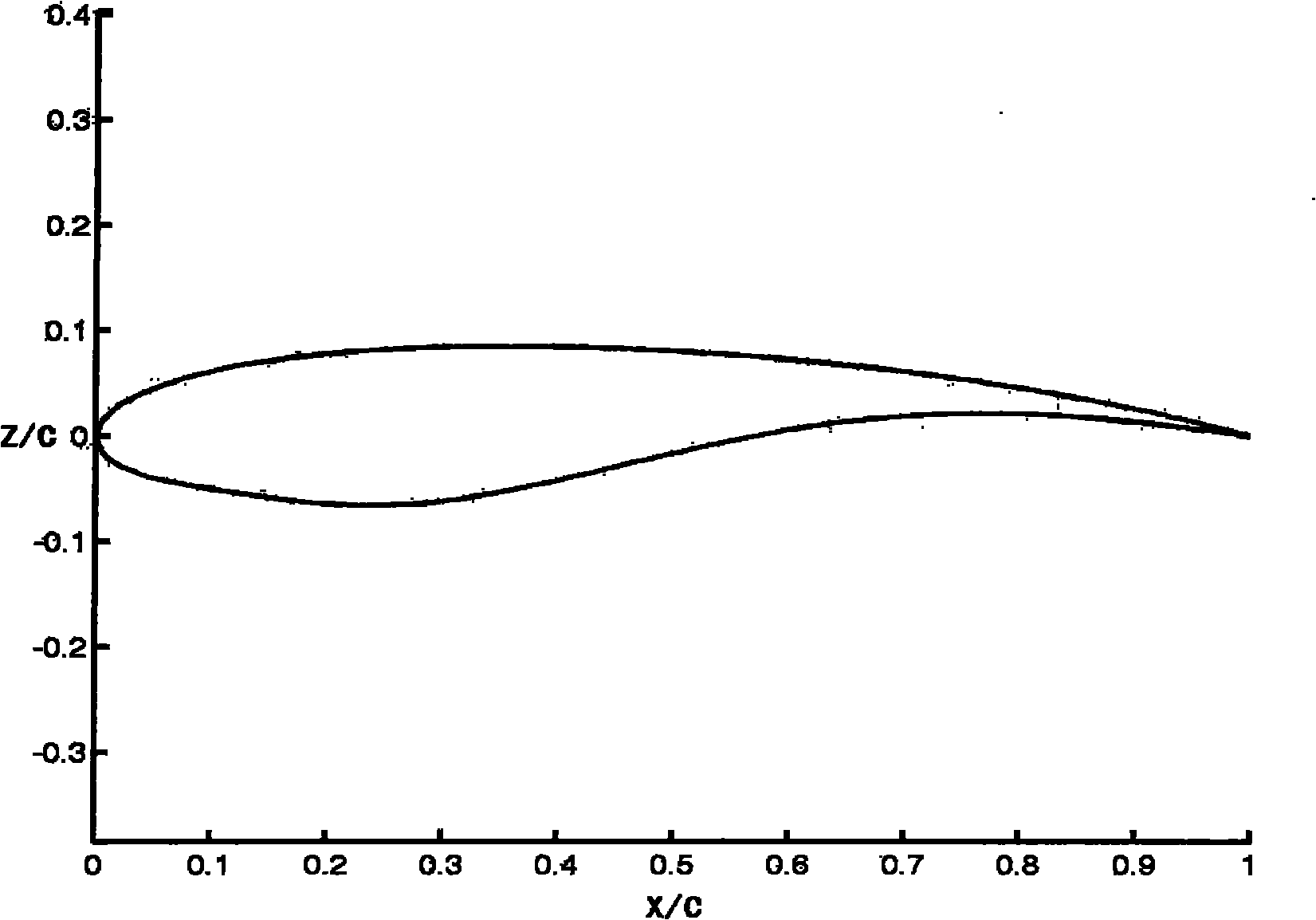

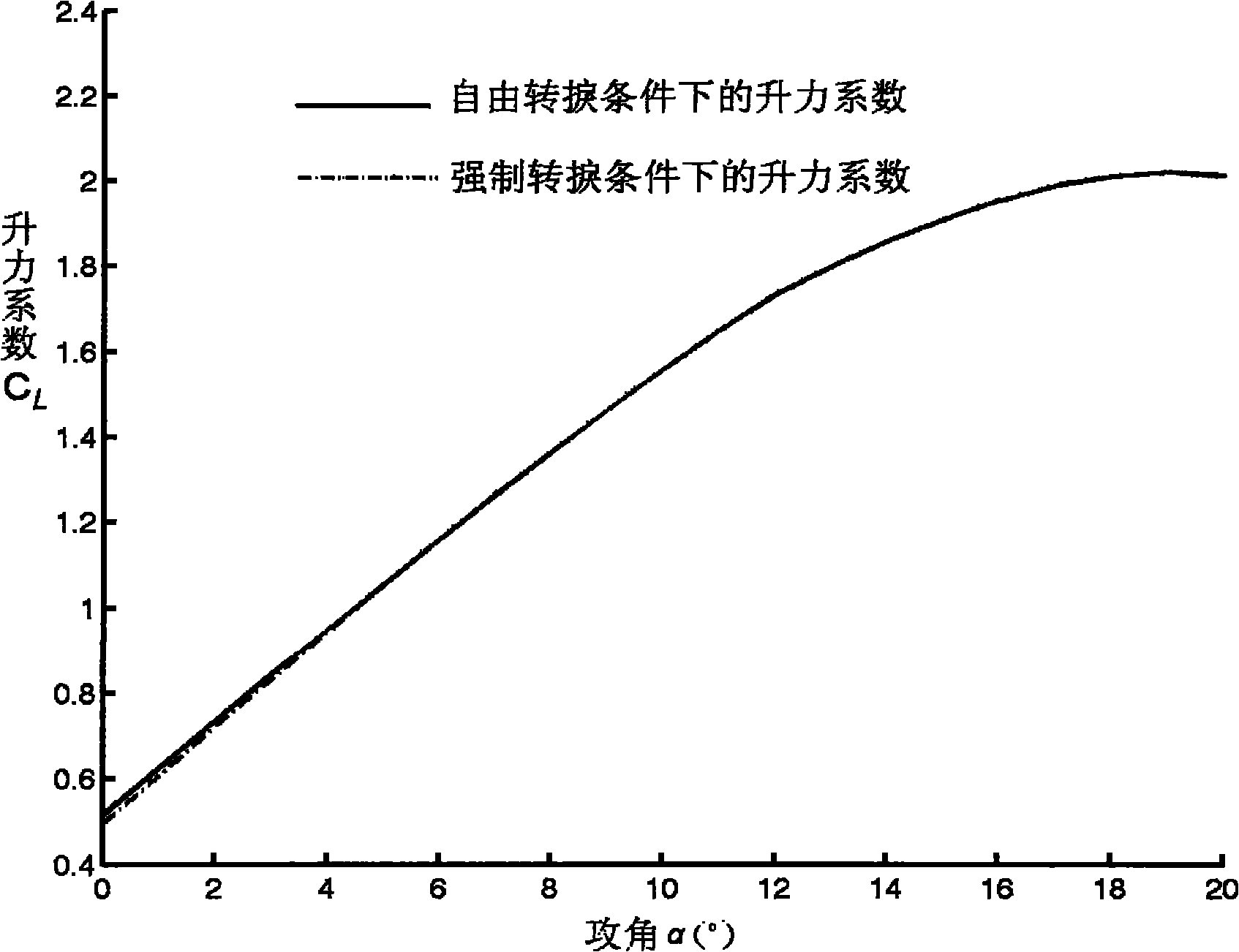

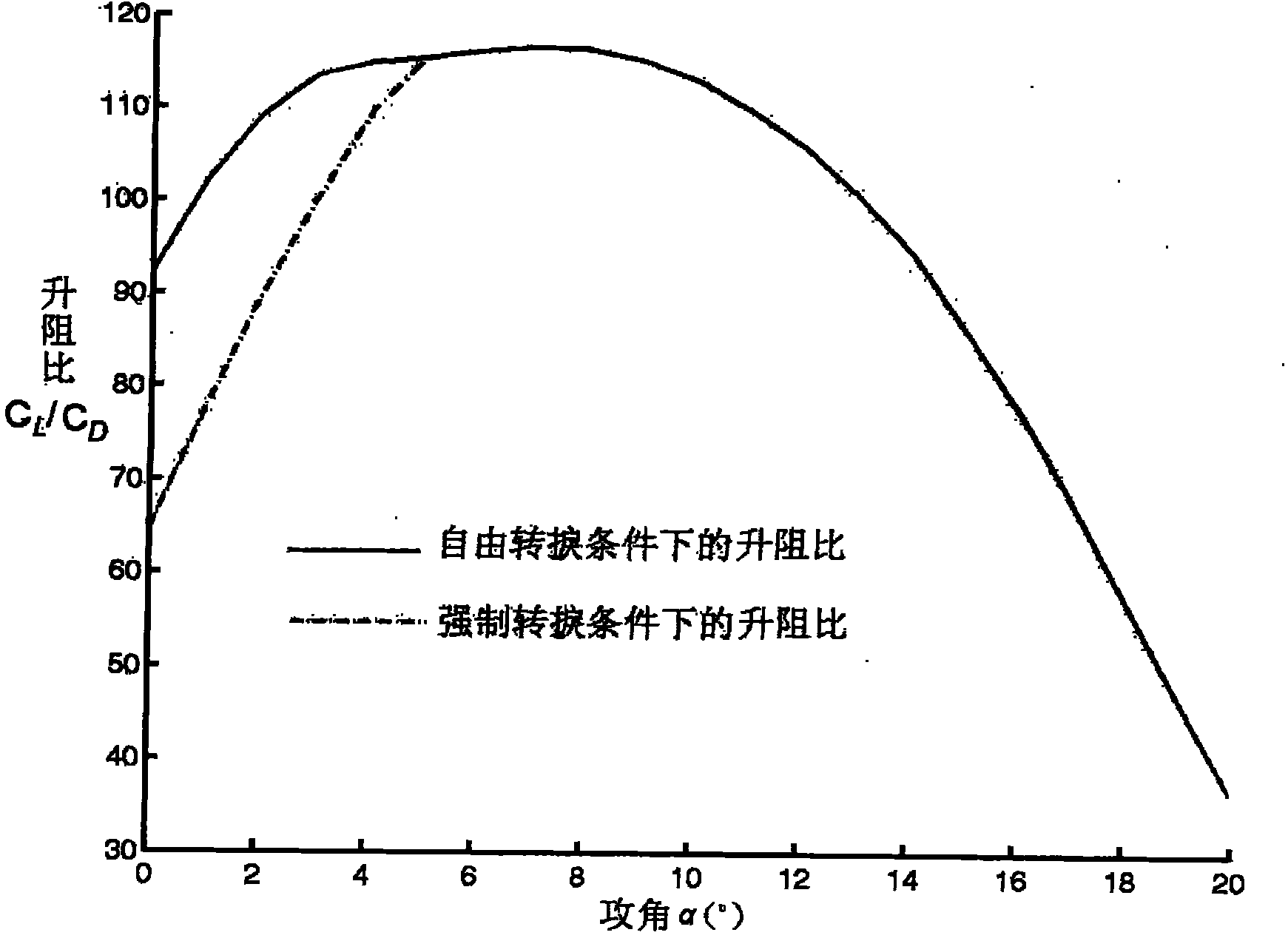

[0036] figure 1 is the airfoil diagram of the present invention, figure 2 Be the variation curve of the lift coefficient of the airfoil of the present invention with the angle of attack, image 3 It is the change curve of the lift-drag ratio of the airfoil of the present invention with the angle of attack, as shown in the figure: the airfoil dedicated to the blade tip of the wind power generator of the present embodiment, the airfoil adopts the PARSEC airfoil expression method, and the equation is When k=1, it represents the upper airfoil, and when k=2, it represents the lower airfoil. is the Z-axis coordinate of the airfoil, and X is the position along the chord length direction, To determine the parameters of the airfoil shape; the parameters 0.01up up xxup dw dw xxdw Substitute for The following two sets of 6-element equations can be obtained:

[0037] Equation one

[0038] a 1 1 = 2 r ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com