Self-adaption variable-rigidity bow wing for micro flapping-wing and flapping rotor crafts

An aircraft and fluttering rotor technology, applied in the field of adaptive variable stiffness bow wing, can solve the problems of complex weight of wing structure, low aerodynamic positive lift and efficiency, high stiffness in the up-shooting stage, etc., and achieve high energy utilization rate, instantaneous The effect of increasing lift and increasing instantaneous lift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

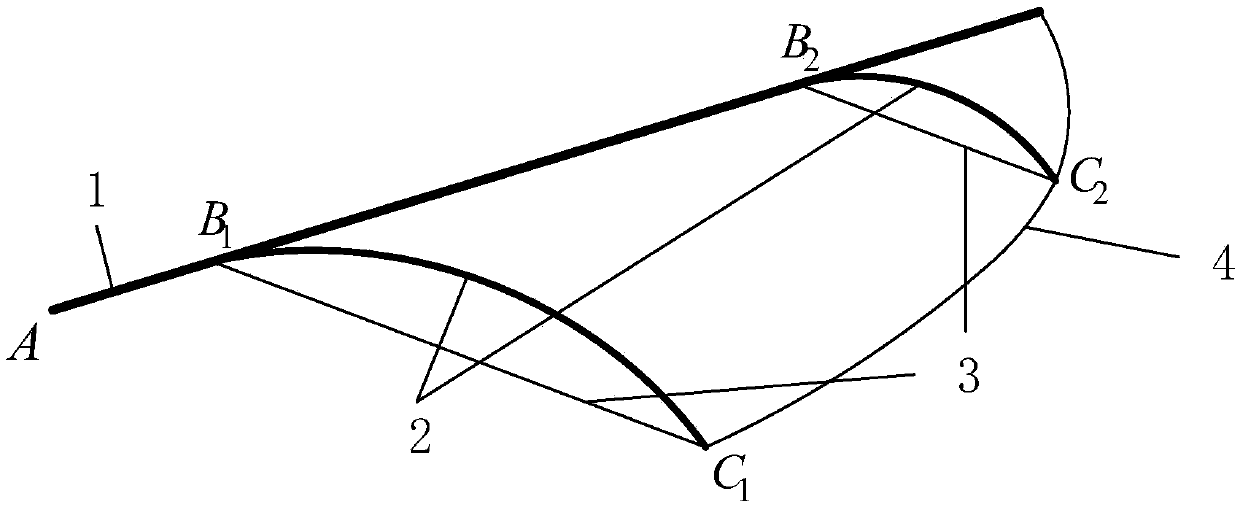

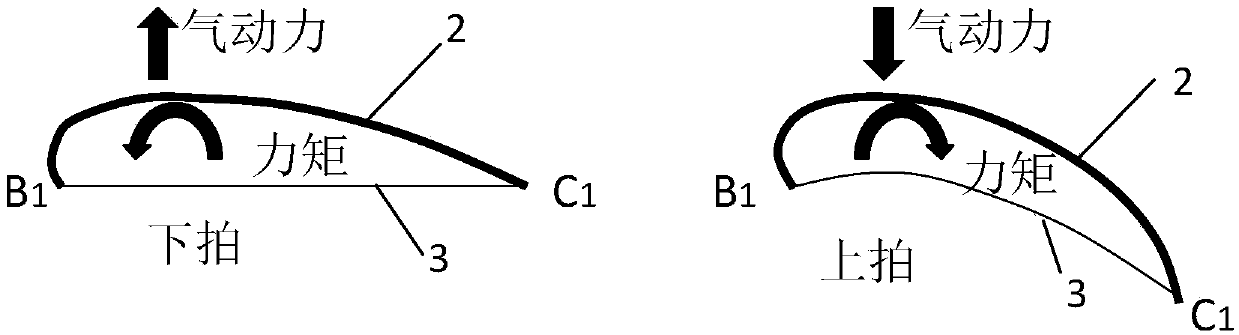

[0048] A kind of self-adaptive variable stiffness arcuate wing for miniature flapping wing and flapping rotor aircraft disclosed in this embodiment, such as figure 1 As shown, it includes main beam 1, arch beam 2, bowstring 3 and membrane 4.

[0049] One side of the wing membrane 4 is fixedly connected to the main beam 1; the arched beam 2 is fixedly connected to the wing membrane 4, and the three arched beams 2 are parallel to each other and perpendicular to the main beam 1; Fixed connection makes the membrane 4 form an arc structure.

[0050] The bow section includes bow beam 2 and bow string 3 .

[0051] The main beam 1 is made of carbon fiber material with a thickness of 0.25mm, the arch beam 2 is made of PC plastic sheet, the bow string 3 is made of fine cotton thread, and the wing membrane 4 is made of 0.02mm thick PVC film.

[0052] The main girder 1 is made of carbon fiber sheets with a thickness of 0.25mm, and the carbon fiber sheets have relatively high rigidity, ens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com