Throttle valve

A throttle valve and valve body technology, which is applied in the directions of fuel air intake, engine control, machine/engine, etc., can solve the problems of low installation accuracy of the throttle valve body and inability to cope with multiple models with different suction volume requirements. , to achieve the effect of improving assembly accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

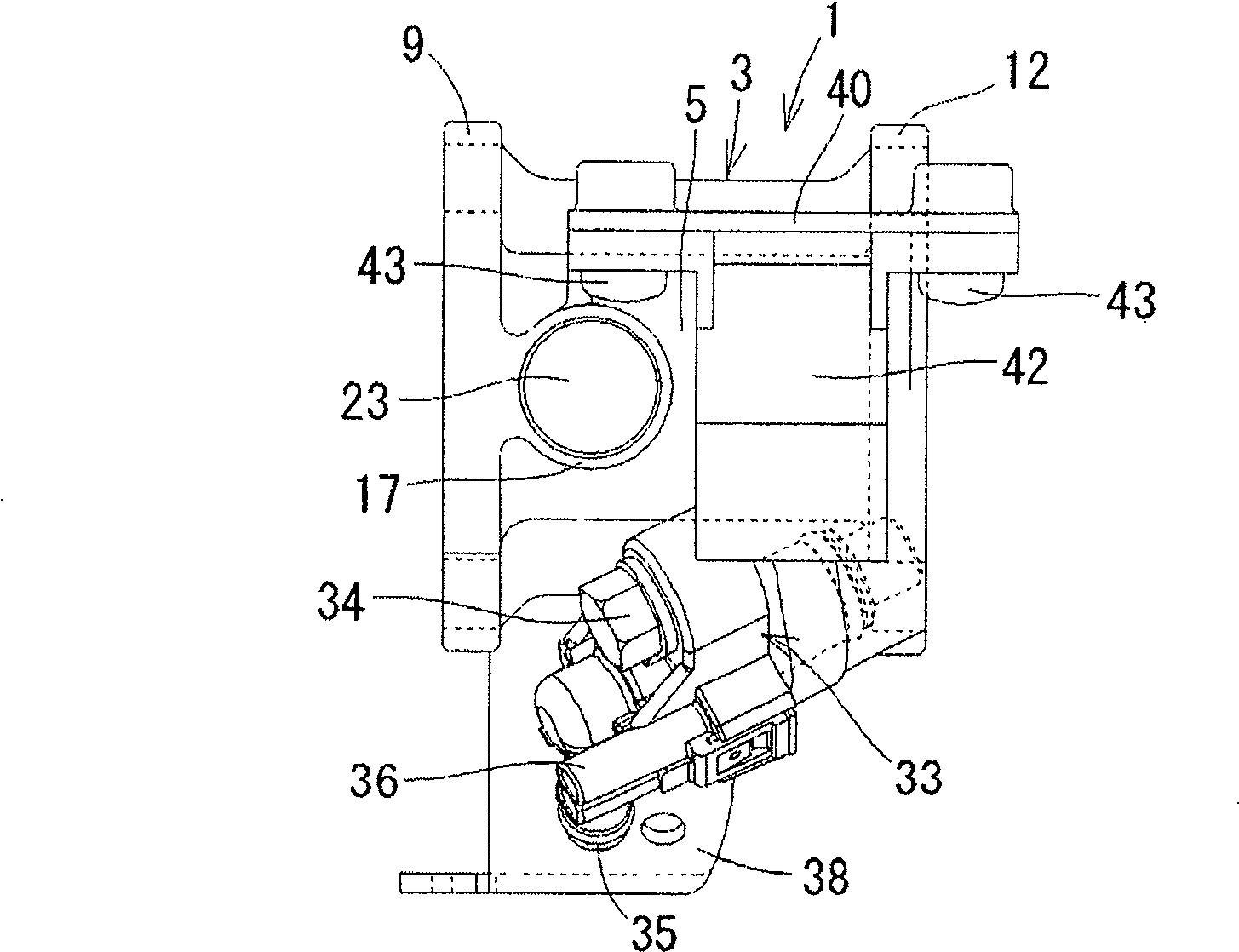

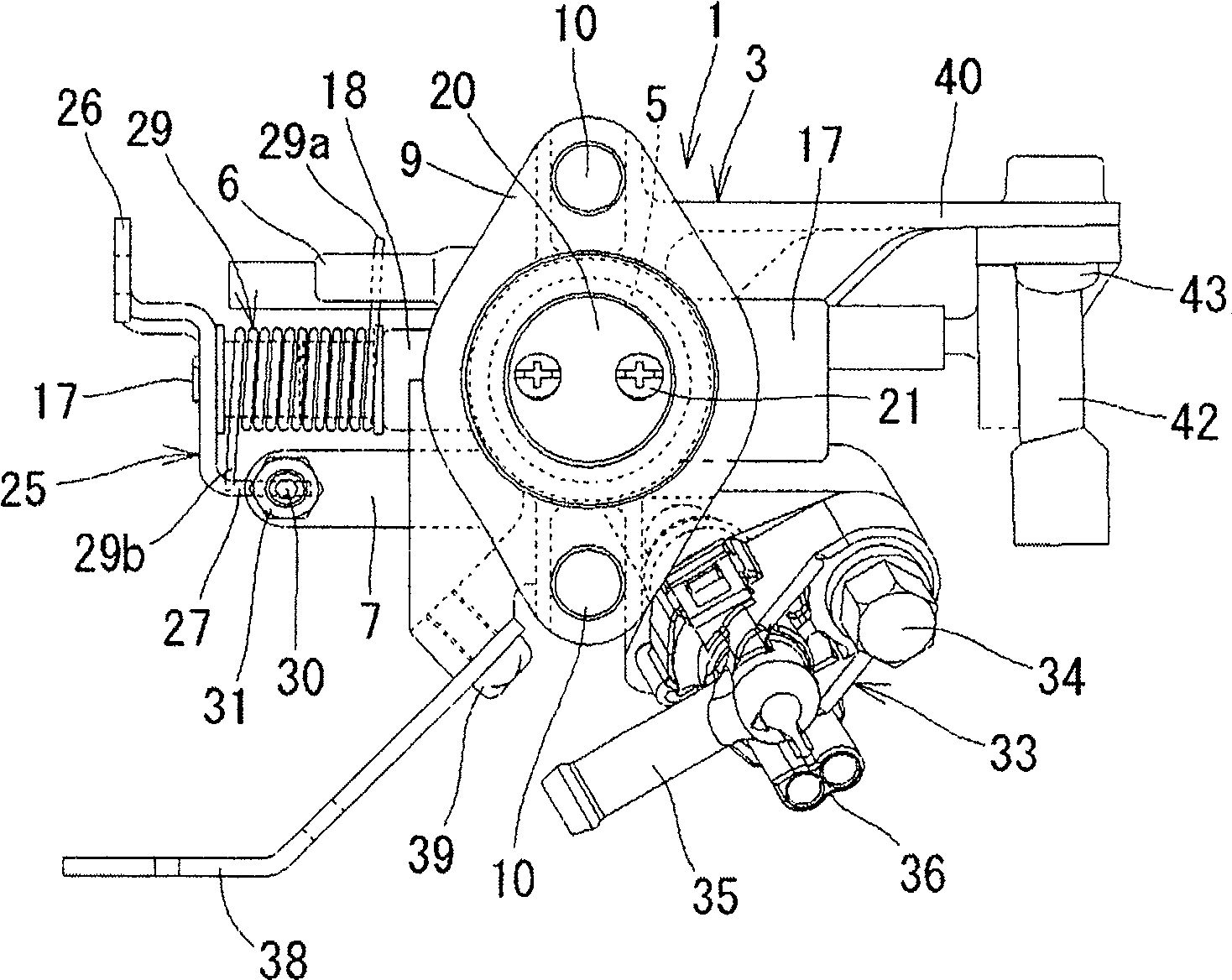

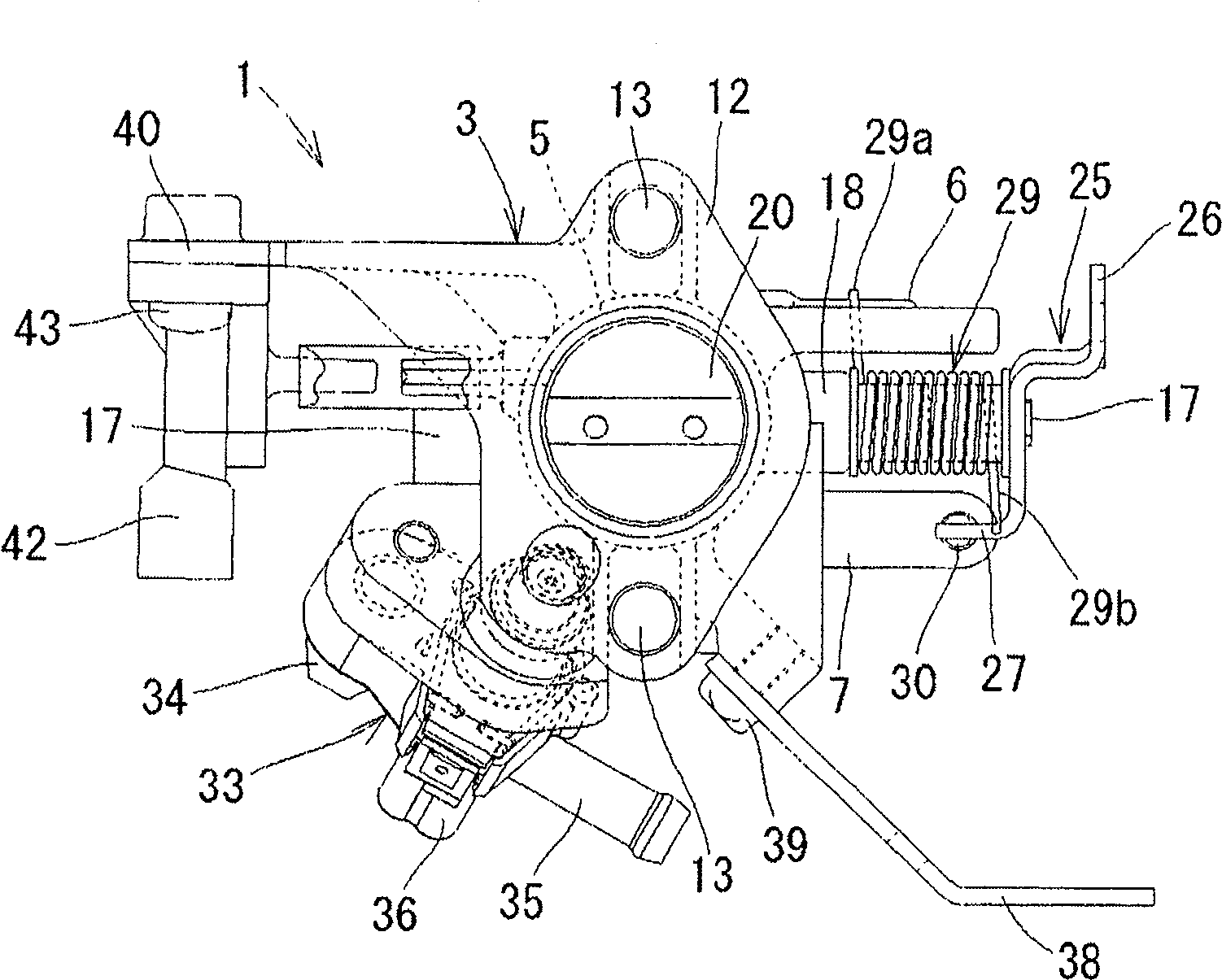

[0028] Next, an embodiment of the present invention will be described with reference to the drawings. This embodiment describes a throttle body used for motorcycles such as motorcycles and motorcycles. and, figure 1 To show the front view of the throttle body, figure 2 for its left view, image 3 for its right side view, Figure 4 for the rear view, Figure 5 For its bottom view, Figure 6 for its cross-sectional view, Figure 7 to represent Figure 6 Enlarged view of Part VII, Figure 8 This is a sectional view showing the main body of the valve body and the throttle member in an exploded manner.

[0029] Such as Figure 6 As shown, the throttle body 1 has a valve body body 3 forming a hole 4 that is an intake passage, and a throttle valve 20 that opens and closes the hole 4 .

[0030] The valve main body 3 is made of, for example, resin, and has a substantially hollow cylindrical hole wall portion 5 . The hole wall part 5 is formed in the Figure 6 The hole 4 pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com