Magnetic coupling pump device

A technology of magnetic coupling pump and pump chamber, applied in pump devices, pumps, non-variable capacity pumps, etc., can solve problems such as deformation or damage, pump efficiency drop, cost increase, etc., to prevent deformation or damage, prolong life, The effect of reducing the axial load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

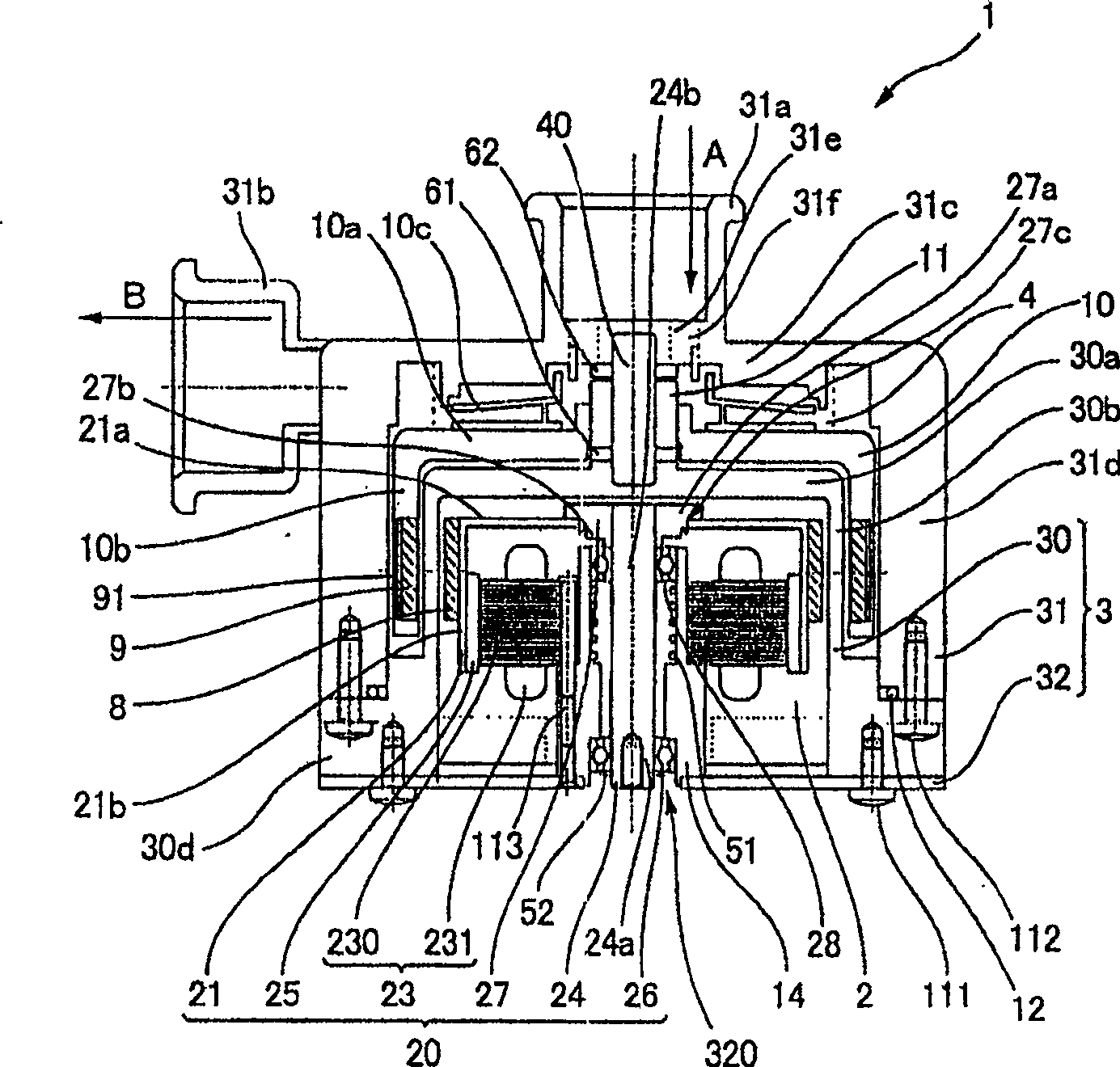

[0028] Next, a magnetic coupling pump device to which the present invention is applied will be described with reference to the drawings.

[0029] (the whole frame)

[0030] figure 1 It is a cross-sectional view of a magnetic coupling pump device to which the present invention is applied. exist figure 1 Among them, the magnetic coupling pump device 1 of this form has a casing 3, which includes a cup-shaped casing 31 with an open bottom, a cup-shaped partition wall 30 installed inside the casing 31, and an end that seals the opening below the partition wall 30. The plate 32 , the end face of the partition wall 30 and the end plate 32 are fixed by bolts 111 . Moreover, the end surface of the case 31 and the flange part 30d of the partition wall 30 are fixed by the bolt 112 in the state which sandwiched the O-ring 12. In the housing 31 , the inflow pipe portion 31 a opens upward, and the outflow pipe portion 31 b opens laterally.

[0031] In the case 3 configured in this wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com