Constant velocity joint

A technology of constant velocity universal joints and guide grooves, which is applied to elastic couplings, mechanical equipment, couplings, etc., and can solve the problem of increased displacement of the roller component 14 and damage to the constant velocity universal joint rotation driving force transmission function, inclination angle θ is limited, etc., to achieve the effect of reducing stress, high degree of design freedom, and improving degree of freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

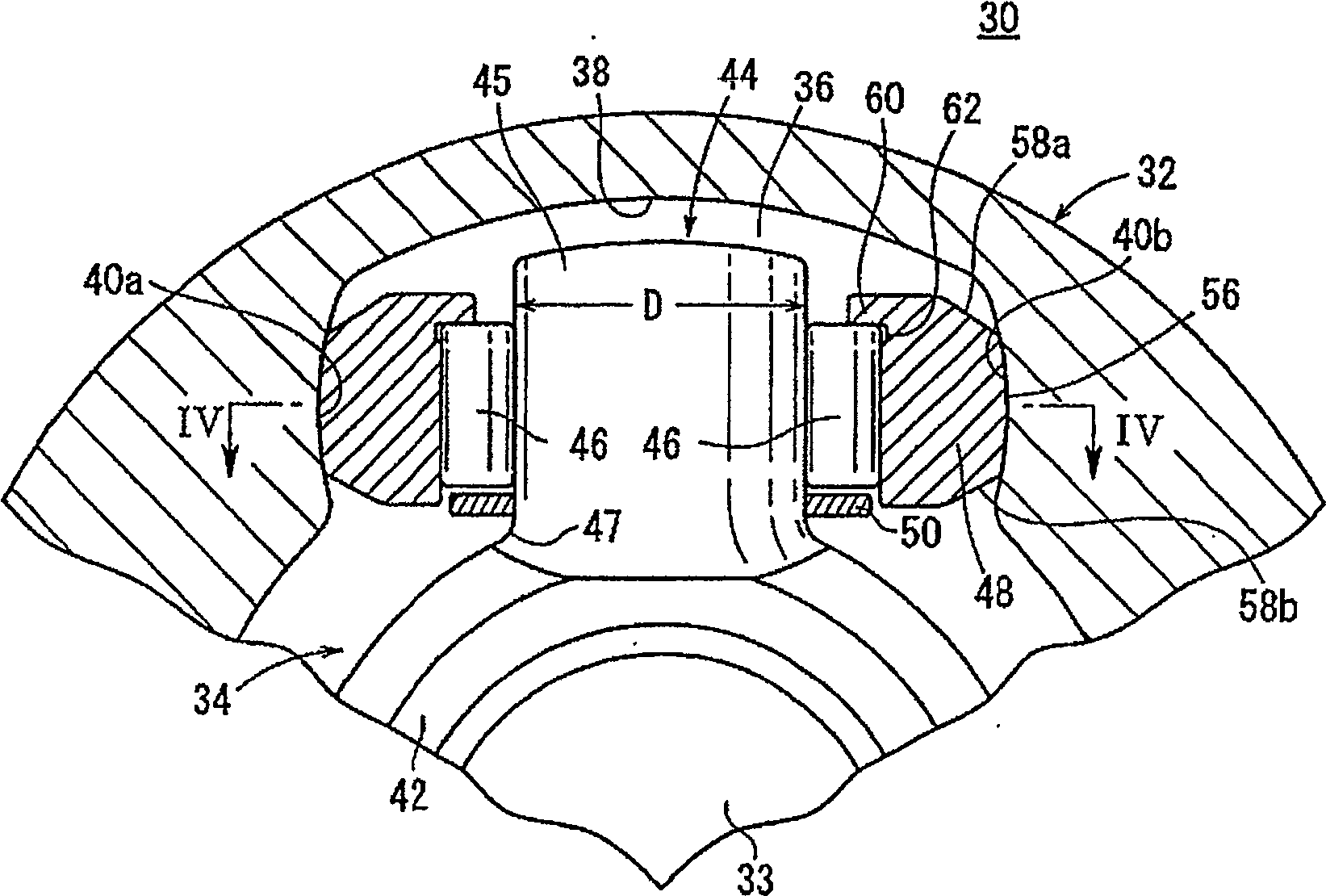

[0064] figure 1 A vertical cross-sectional view of main parts along a direction perpendicular to the axis of the constant velocity joint 30 according to the first embodiment of the present invention is shown. The constant velocity joint 30 mainly includes: a cylindrical outer member 32 integrally connected to one end of one transmission shaft (not shown) and having an opening; The inner part 34 in the inner space portion of the outer part 32 .

[0065] Three guide grooves 36 extending in the axial direction and spaced 120 degrees from each other around the axis are formed in the inner space portion of the outer member 32 . The guide groove 36 includes: a top plate portion 38 having a gently curved cross section; and sliding portions 40 a , 40 b facing each other on both sides of the top plate portion 38 and having an arcuate cross section.

[0066] An annular tripod 42 constituting the inner member 34 is externally fitted on the transmission shaft 33 . Three trunnions 44 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com