Micro capsule having carbamide resin wall

A technology of microcapsules and isocyanurate, which is applied in the direction of microcapsule preparation, microsphere preparation, replication/labeling methods, etc., and can solve the problems of expensive and high cost of microcapsules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

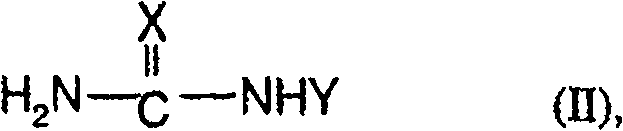

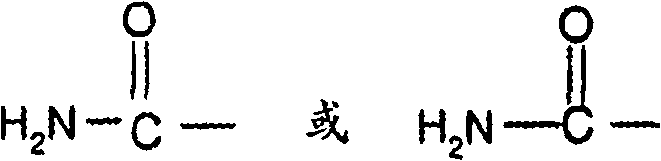

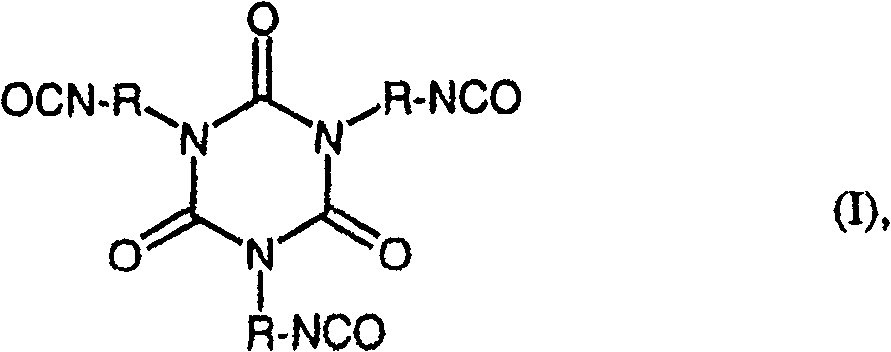

Method used

Image

Examples

Embodiment 1a

[0095] Example 1a (comparative example)

[0096] A microcapsule dispersion was produced according to example 10 of US 5,635,211 (=EP-A-727 251 ) by using guanidine as crosslinker.

Embodiment 1b

[0097] Example 1b (this invention)

[0098] Corresponding microcapsules according to the invention were produced under the same conditions as in Example 1a by using guanidine carbonate as crosslinker instead of guanidine, and the two capsules were compared with respect to their properties (see table). The NCO content in Examples 1a and 1b was 21.6% and the isocyanurate content was 96.9%, based on the polyisocyanate used. Among them, hexamethylene diisocyanurate trimer accounts for >45 wt% and higher oligomer accounts for >30 wt%.

[0099] surface

[0100]

[0101] * Aging was assessed by comparing a copy of a properly aged CB (coated back) paper to a copy of an unaged CB paper as a reference. The higher the number, the stronger the copy.

[0102] ** Corresponding to the polyisocyanate content in the oil phase.

[0103] The microcapsules according to the invention show much better aging properties than those of the prior art, despite a significantly reduced wall frac...

Embodiment 2

[0104] Example 2 (this invention)

[0105] a) Production of microcapsule dispersions

[0106] The microcapsules that are used for carbonless copy paper are obtained by following steps: first by dissolving the coupler that is made up of 12g crystal violet lactone in 187.2g diisopropylnaphthalene at 120 ℃ and this solution and 20g embodiment 1 The polyisocyanurate was mixed at room temperature to prepare the oil phase. 280.8 g of a naphthenic isoparaffin mixture were added as extender. This oil phase was mixed with 442.3 g of an aqueous phase consisting of an aqueous solution of polyvinyl alcohol (5.3 g in 437 g of water), and the mixture was stirred to obtain a coarse pre-emulsion, which was mixed with a mixing siren (8950 rpm ) were emulsified for 8 minutes to obtain a fine emulsion. The obtained miniemulsion was mixed with an aqueous solution of guanidinium carbonate (7.0 g in 50.7 g of deionized water) at room temperature, the obtained mixture was heated to 60° C. with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com