Dielectric ceramic composition and electronic device

一种陶瓷组合物、电介质的技术,应用在固定电容器电介质、固定电容的零部件、陶瓷等方向,能够解决难产品实际使用、IR温度依赖性不好、介电常数高等问题,达到电容老化特性良好、低成本化、经时变化小的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

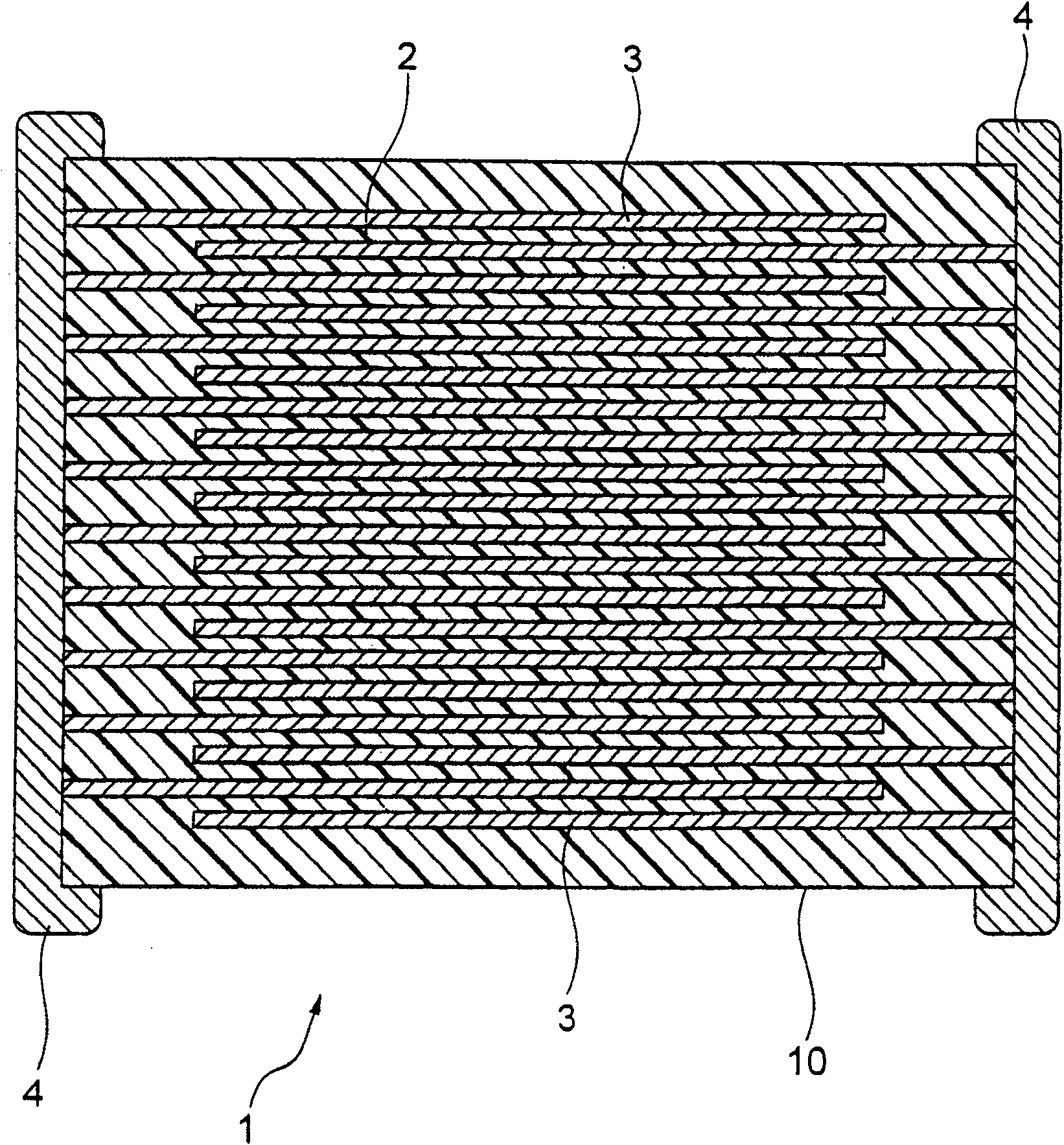

[0148] In the examples, samples of multilayer ceramic capacitors were produced through the procedures shown below.

[0149] Preparation of each paste

[0150] First, the starting materials (BaCO 3 , CaCO 3 、TiO 2 ) and the first to sixth subcomponent raw materials. In this example, carbonate (secondary component: MgCO 3 , the third sub-component: MnCO 3 ), using oxides in other raw materials (the first subcomponent: Y 2 o 3 、Dy 2 o 3 or Ho 2 o 3 , the fourth sub-component: Al 2 o 3 , the fifth secondary component: V 2 o 5 , the sixth secondary component: (Ba 0.6 Ca 0.4 ) SiO 3 (indicated as BCG in the table)). In addition, (Ba 0.6 Ca 0.4 ) SiO 3 by using a ball mill to BaCO 3 , CaCO 3 and SiO 2 It was wet-mixed for 16 hours, dried, sintered in air at a temperature of 1150° C., and wet-pulverized by a ball mill for 100 hours.

[0151] Next, the starting material for preparing the main component and the first subcomponent raw material (Y 2 o 3 、Dy 2...

Embodiment 2

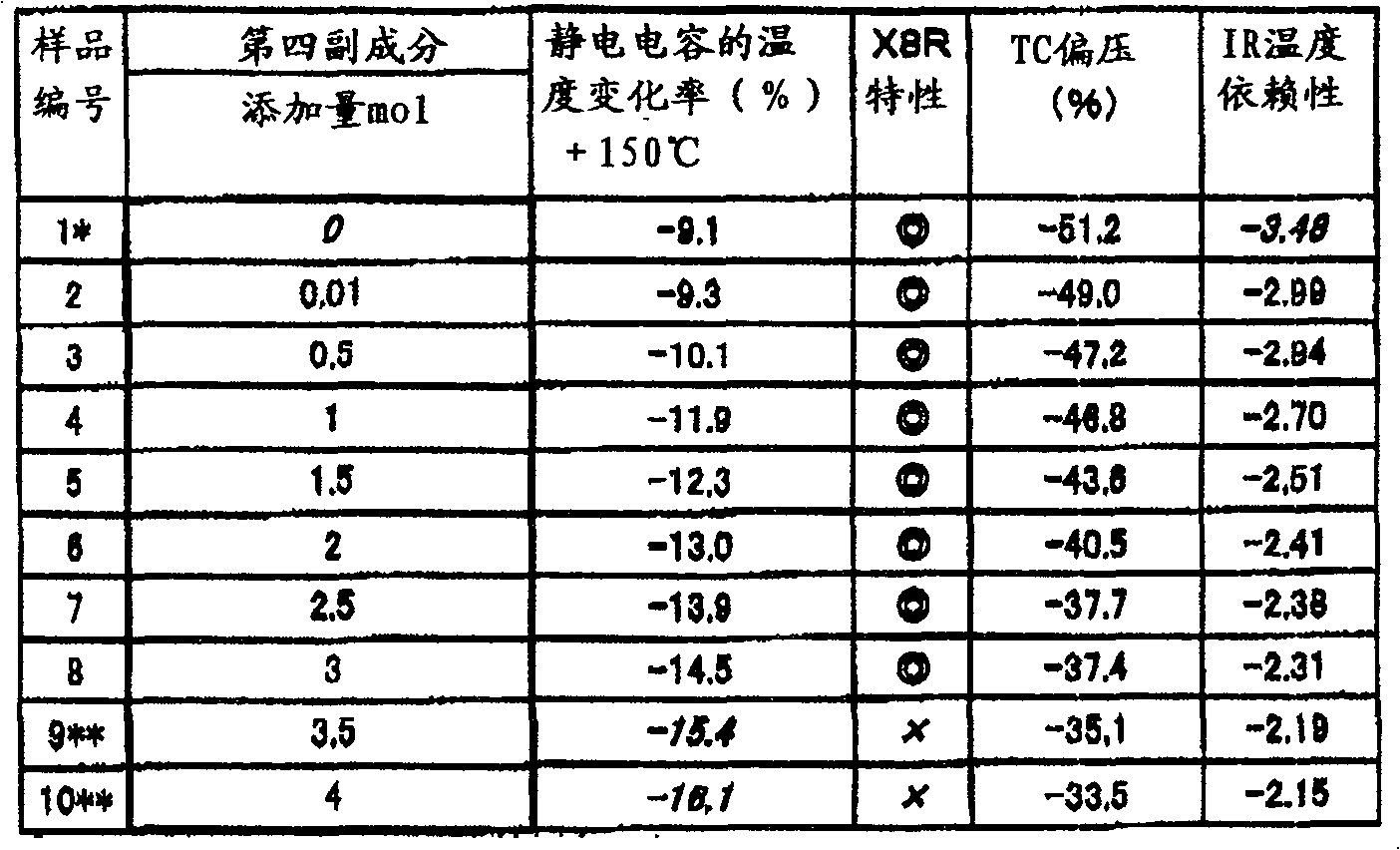

[0207] Capacitor samples were produced in the same manner as in Example 1 except that the type and content of the fourth subcomponent raw material were changed as shown in Tables 4 to 7, and the same evaluation was performed.

[0208] Table 4

[0209]

[0210] Samples marked with [*] represent comparative examples of the present invention.

[0211] Samples marked with [**] represent reference examples of the present invention.

[0212] Among them, the composition of the main component, the composition and addition amount of the first to third, fifth, and sixth subcomponents are the same as those in Table 1.

[0213] The fourth subcomponent: Cr 2 o 3

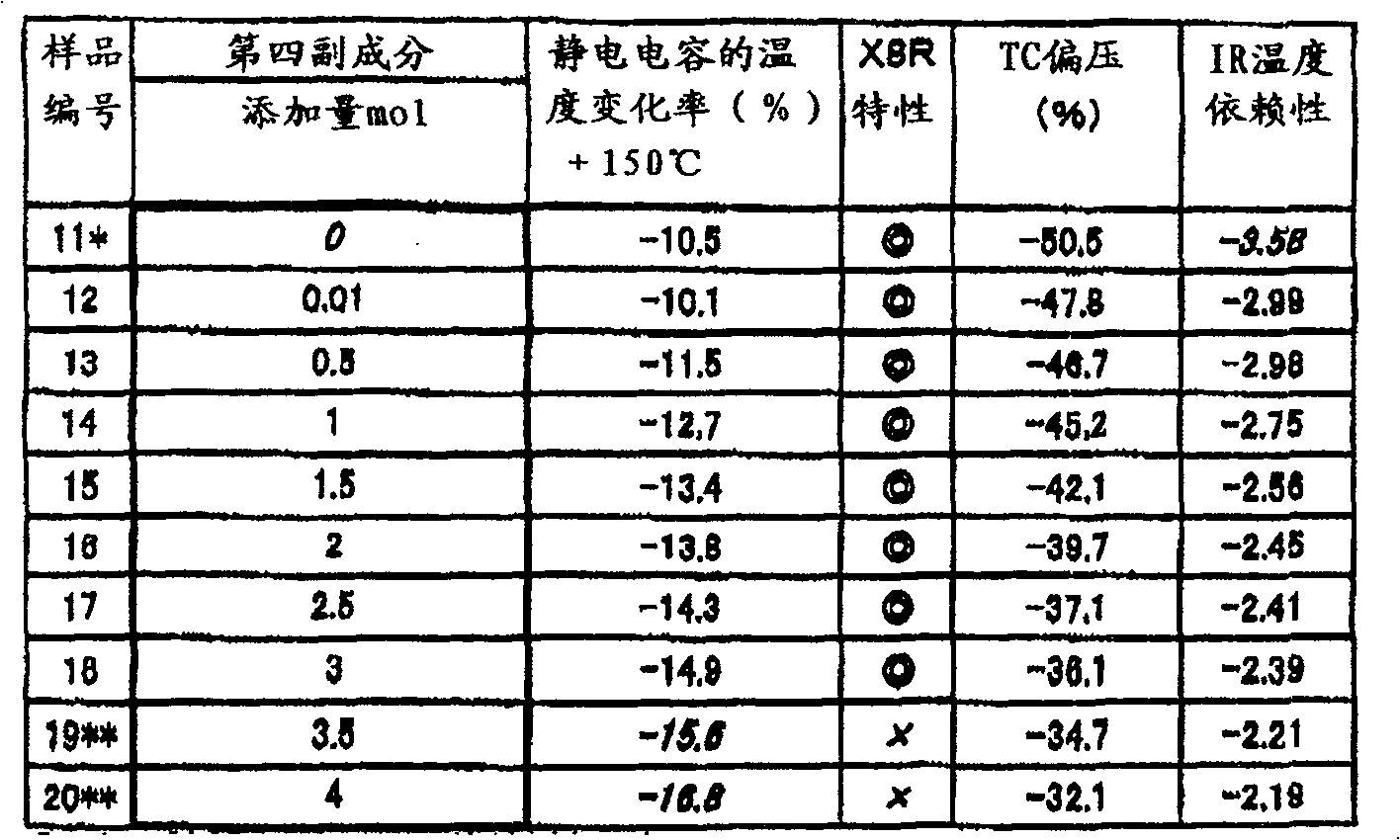

[0214] table 5

[0215]

[0216] Samples marked with [*] represent comparative examples of the present invention.

[0217] Samples marked with [**] represent reference examples of the present invention.

[0218] Among them, the composition of the main component, the composition and addition amount of the first to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com