An anti-galling rigid phase-to-ground spacer

A spacer and anti-galling technology, which is applied in the field of spacer, can solve the problems of damage to the wire connection hardware of the spacer, transmission line and tower hazards, etc., to prevent theft and damage, prevent pollution, and ensure safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

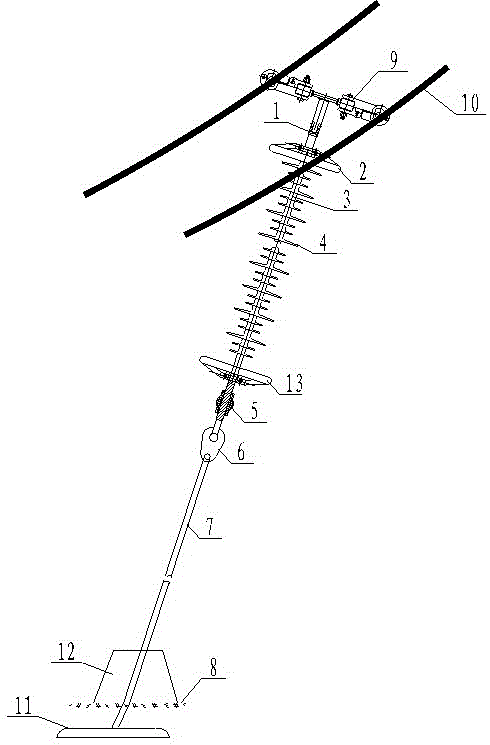

[0026] The invention can be applied to high-voltage transmission lines in the range of 110kV to 1000kV.

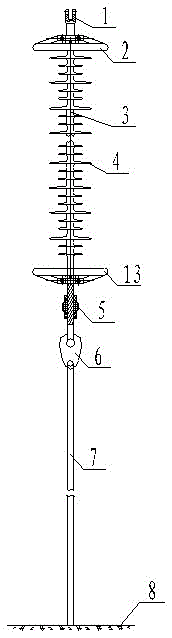

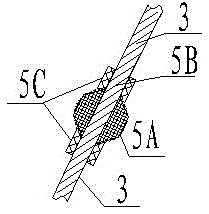

[0027] Such as figure 1 As shown, the present invention includes a rigid rod body 3, an insulating shed 4, an adjustment plate 6 and a stay wire 7, the rigid rod body 3 is made of an inner epoxy resin glass drawing rod and an outer silicone rubber composite material layer, and the insulating shed shed 4 and silicone rubber composite material layer integrated structure.

[0028] The upper and lower ends of the rigid rod body 3 are respectively connected with a high-voltage end fitting 1 (connecting fitting) and an adjustment plate 6 , and the high-voltage end fitting 1 is used to connect the sub-spacers 9 . On the rigid rod body 3 between the high-voltage end fittings 1 and the adjusting plate 6, there are two end accessories: the upper pressure equalizing ring 2 and the lower pressure equalizing ring 13, and the upper pressure equalizing ring 2 and the lower pressure equa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com