Compacting roller

A technology of compacting rollers and hydraulic pressure, applied in the field of compacting rollers, which can solve problems such as height imbalance and acceleration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

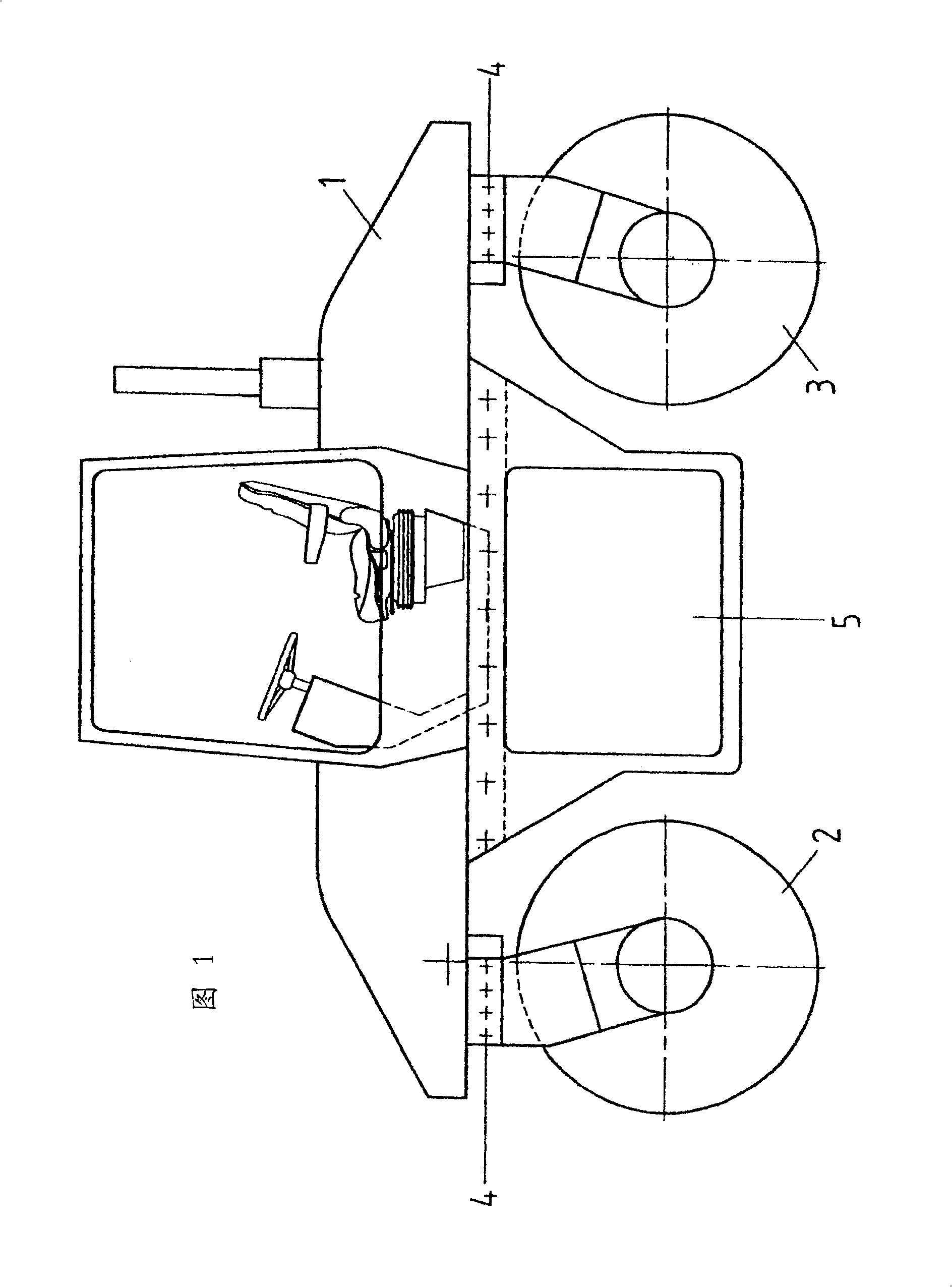

[0023] figure 1 The shown tandem roller comprises a superstructure 1 with a driver's cab, rolling bodies 2 and 3 mounted at the front and rear under said superstructure 1 via steerable swivel couplings 4 . Between the two rolling bodies 2, 3 is an engine compartment 5 in which the drive motor, usually a diesel engine, is housed.

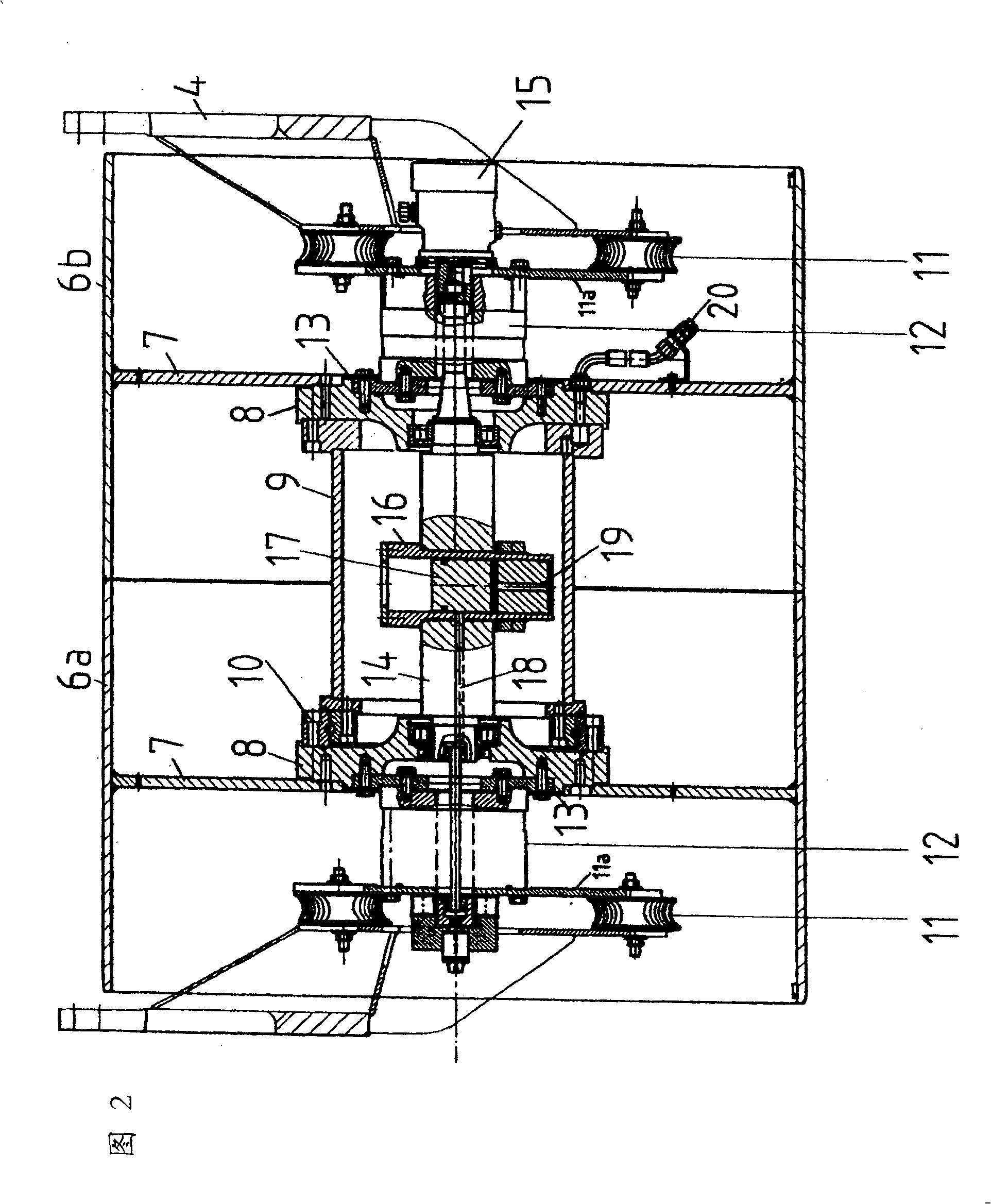

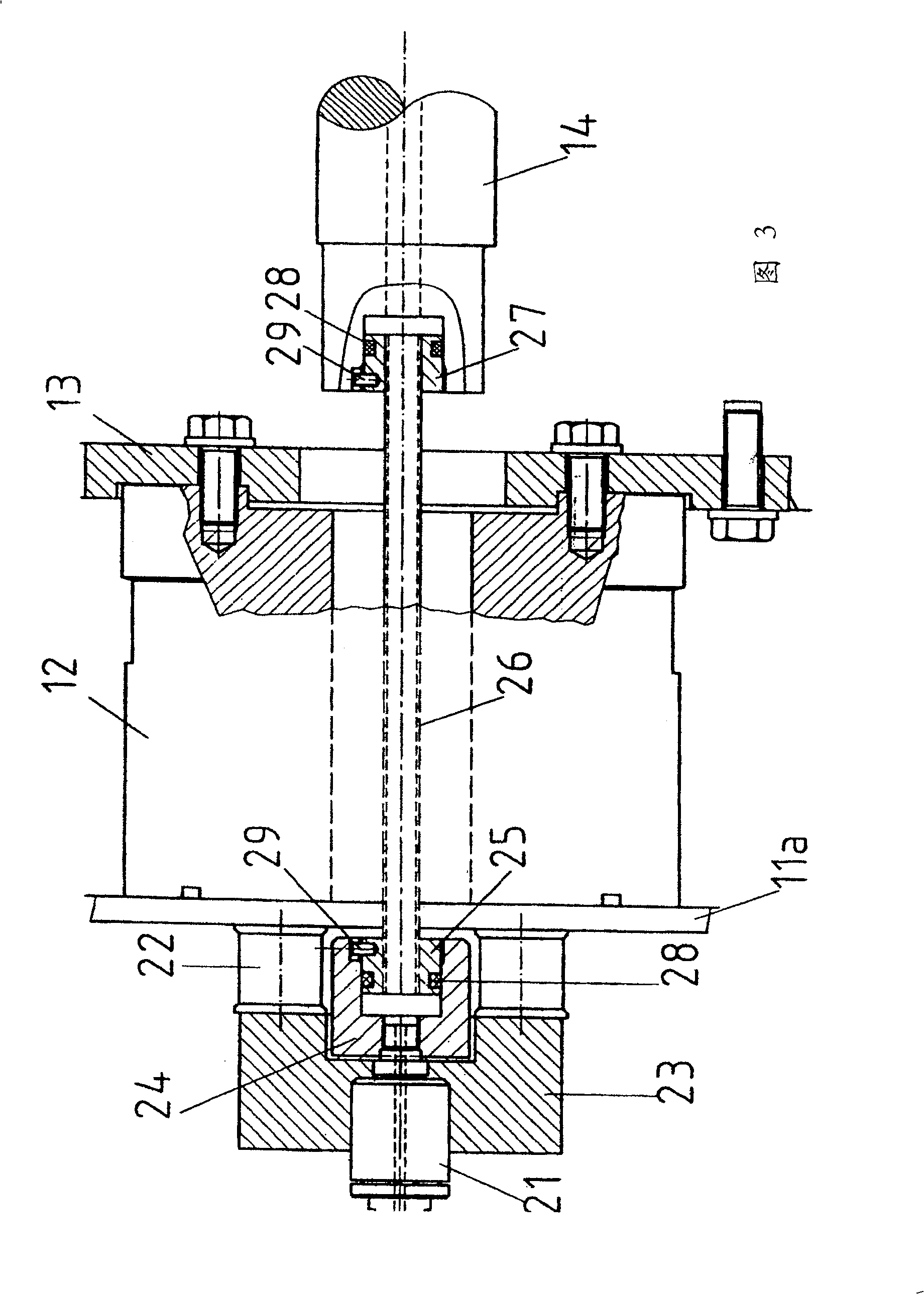

[0024] Such as figure 2 As shown, the front and / or rear rolling elements 2, 3 comprise two tire halves 6a, 6b arranged axially side by side and a corresponding radially extending tire end plate 7, the tire end plate 7 Has a central through hole. A corresponding bearing flange 8 is fastened on the tire end plate 7 . The two tire halves 6a, 6b are connected to each other so as to be rotatable about the axis of the rolling bodies via the two bearing flanges 8 and the spacer tube 9 via a bearing 10, for example arranged between the bearing flange 8 and the spacer tube 9 between the roller bearings.

[0025] The swivel coupling 4, which is steerably...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com