Paper strip debugging method for paper product processing

A debugging method and technology of paper strips, which are applied in thin material handling, packaging, and delivery of objects, etc., can solve problems such as uneven thickness of paper and unsmooth packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following is further described in detail through specific implementation methods:

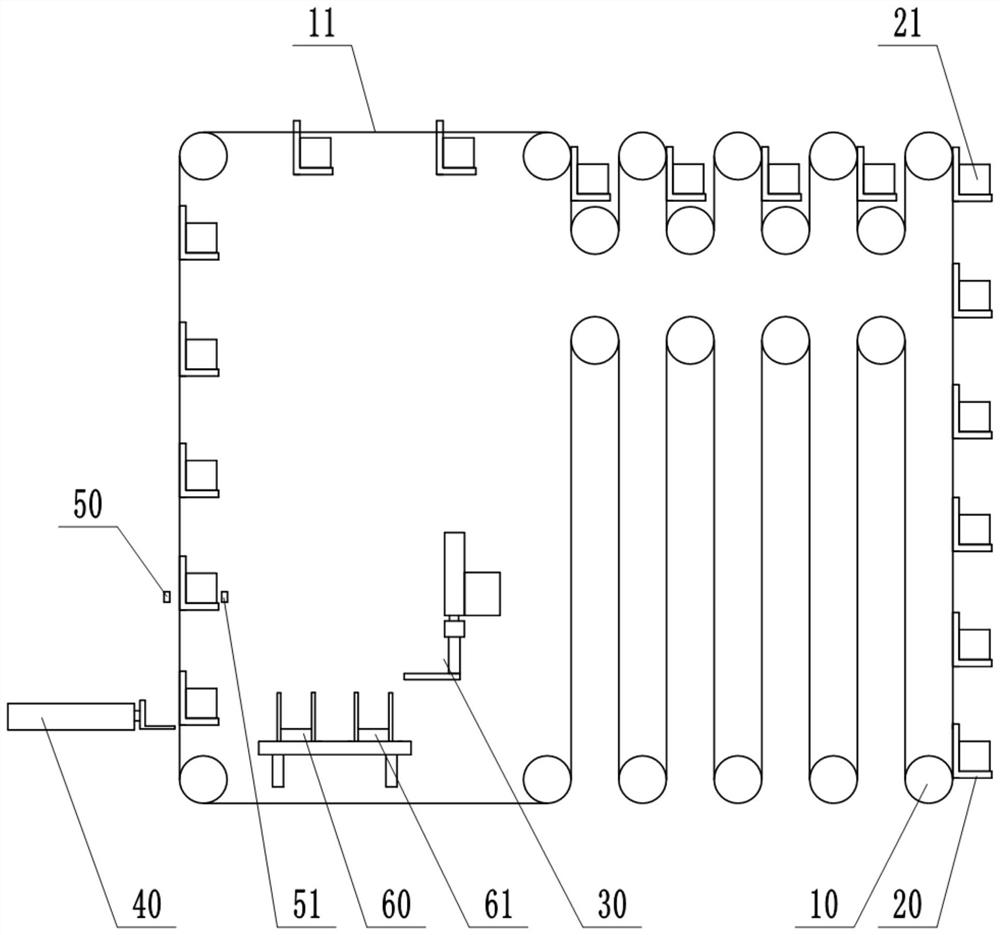

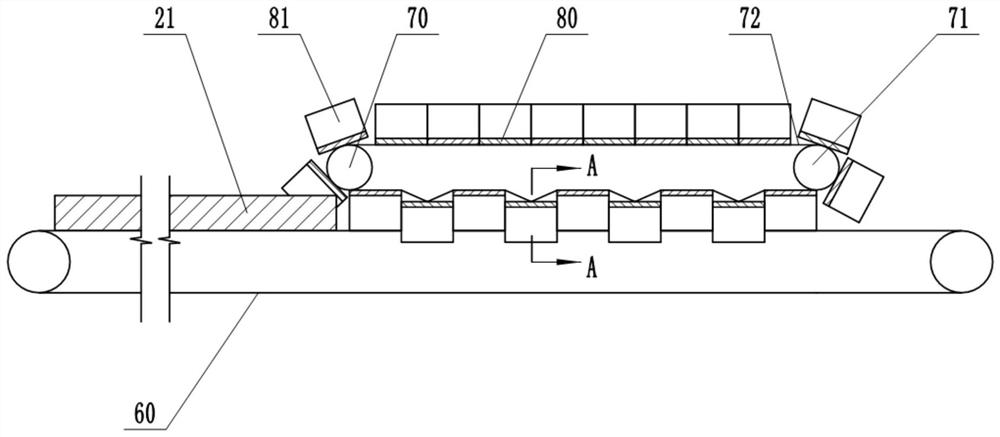

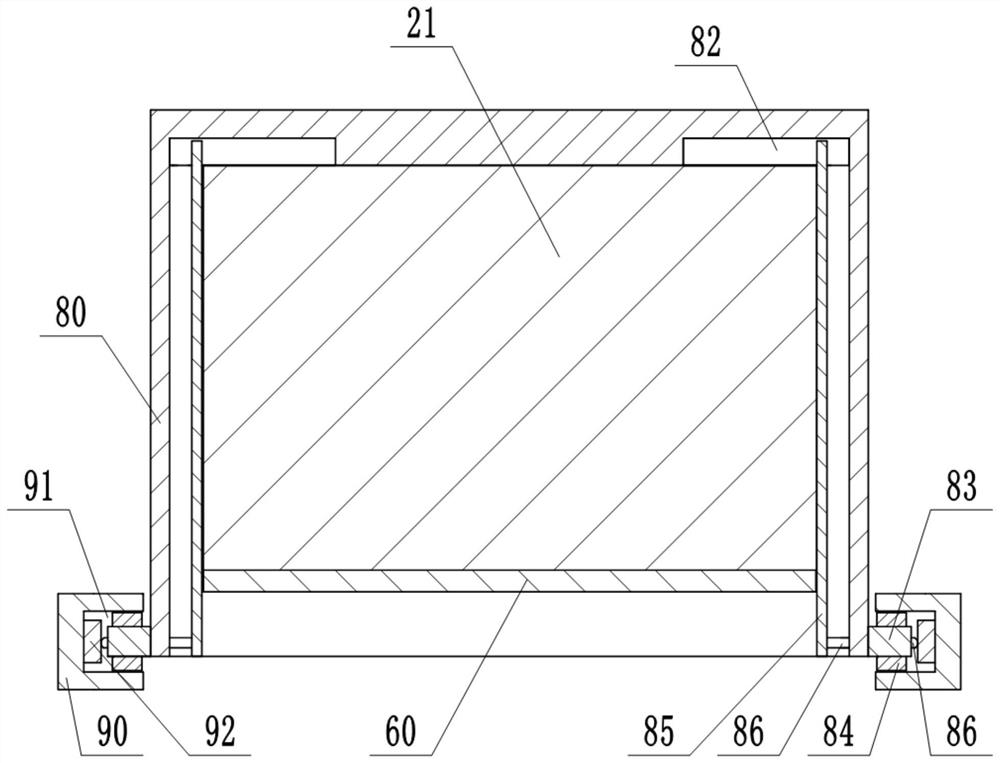

[0025] The reference numerals in the drawings of the description include: sprocket 10, transmission chain 11, bracket 20, stacked paper strip 21, paper receiving mechanism 30, paper pushing mechanism 40, light source transmitter 50, light source receiver 51, first conveying Belt 60, second conveyor belt 61, driving roller 70, driven roller 71, conveyor belt 72, pressing block 80, pressing groove 81, sliding groove 82, card strip 83, roller 84, pressing plate 85, push rod 86, rectangular strip 90 , chute 91, raised bar 92.

[0026] Paper strip debugging method for paper product processing, the paper storage rack will be used in the paper strip debugging process in this scheme, such as figure 1As shown, the paper storage rack includes a frame, a controller, a paper storage device and an output device. The paper storage device includes two drive chain sets arranged symmetrically on op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com