Three-way electromagnetical valve

An electromagnetic three-way valve and electromagnetic control technology, applied in the direction of rotary piston machinery, machine/engine, rotary piston pump, etc., can solve the problems of low life, high cost, complex structure, etc., and achieve long life, low cost, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The preferred embodiments of the novel electromagnetic three-way valve of the present invention will be described in detail below with reference to the accompanying drawings.

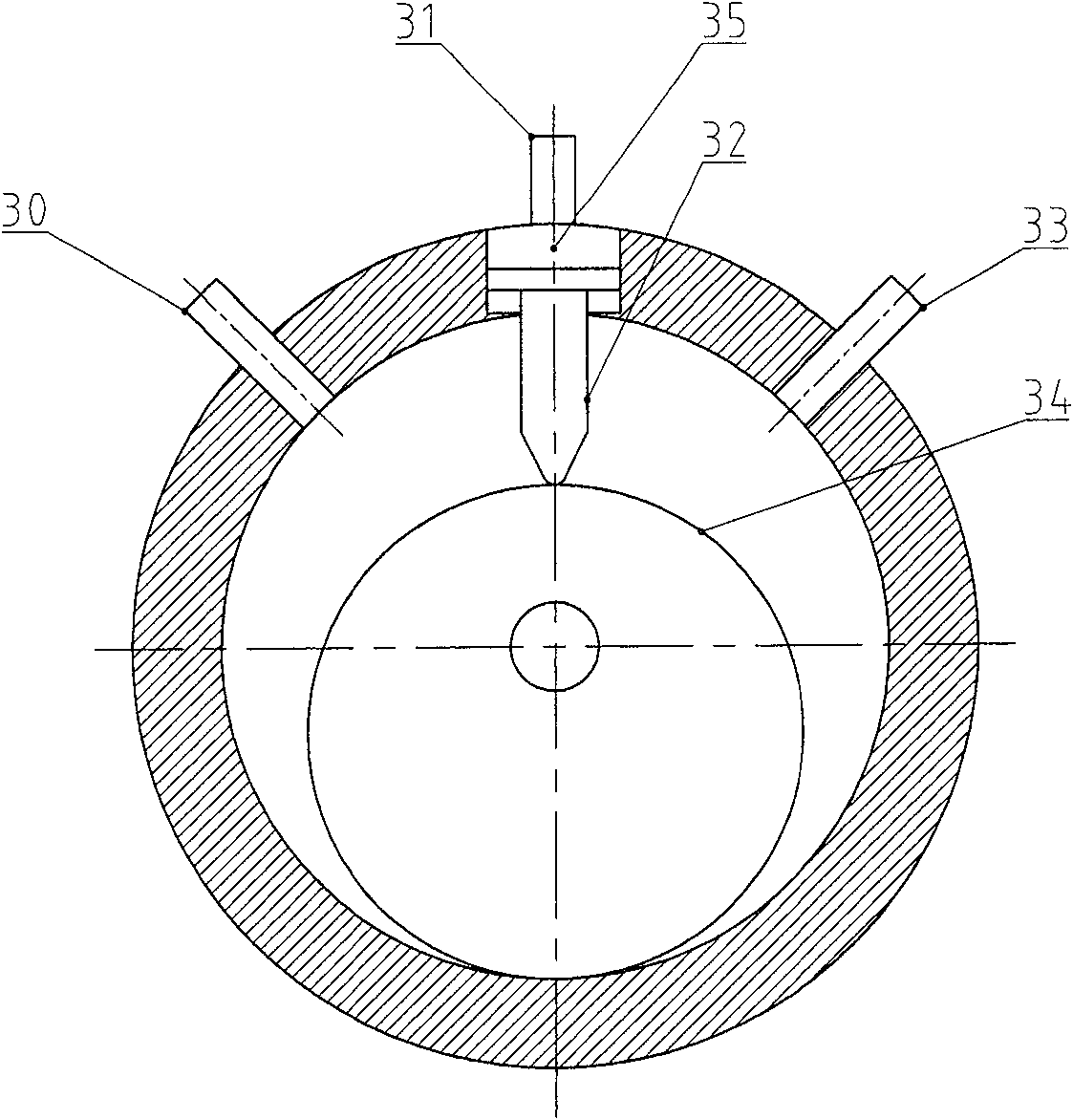

[0045] Figure 4 It is a cross-sectional view of a preferred embodiment of the present invention, which shows the internal structure of the electromagnetic three-way valve of the present invention. As shown in the figure, the new electromagnetic three-way valve includes an electromagnetic control component part, a valve body 6, and a high-pressure cut-off valve part.

[0046] see Figure 4 , which shows a typical structure of the electromagnetic control assembly part, which includes an outer tube 13, an electromagnetic coil 3 located outside the outer tube 13, and a static iron core (fixed iron core) 1 and a soft magnet (moving iron core) located in the outer tube 13 Core) 4, wherein a first elastic element such as a compression spring 2 is arranged between the static iron core 1 and the moving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com