Environment-friendly surface glue film dry-pressing resin and application method thereof

An environment-friendly, surface-layer technology, applied in pigment-containing coatings, paper, textiles and papermaking, etc., can solve the problems of inability to use color digital printing paper, high production efficiency, high defective rate, etc., and achieve bright colors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

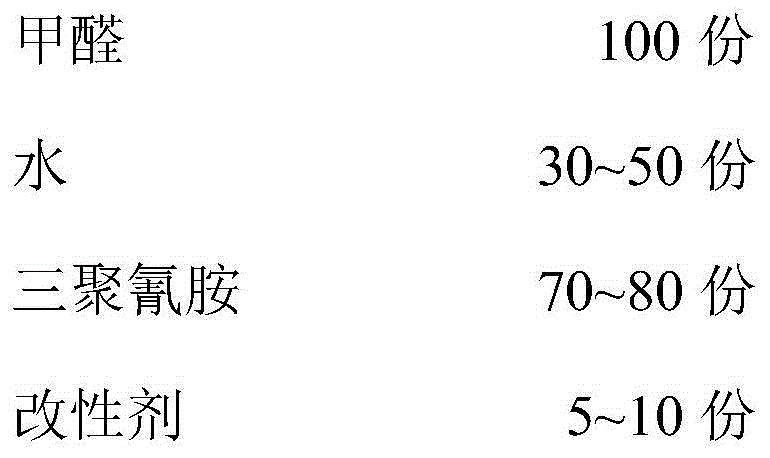

[0024] 1. Preparation of melamine resin:

[0025] (1) Put 100kg of formaldehyde and 40kg of water into the reactor, add 8kg of modifier, stir evenly, and adjust the pH to 9.0-10 with 30% sodium hydroxide by mass fraction;

[0026] (2) 78kg of melamine is dropped into the reactor, and the temperature is raised to 94-96°C for 70min at a rate of 1.5°C / min;

[0027] (3) When the ratio of resin to water is detected to be 1:2.6-3.0 at 25° C., the temperature is lowered to 40° C. and discharged to obtain the melamine resin.

[0028] The parameters of the prepared melamine resin are as follows: the viscosity is 0.35-0.4 Pa·s, the water mixing ratio is 1:1.8-2.0, the density is 1.18-1.2 g / cm3, and the solid content is 48-52%.

[0029] 2. Preparation of environment-friendly transparent surface dry-pressed film material

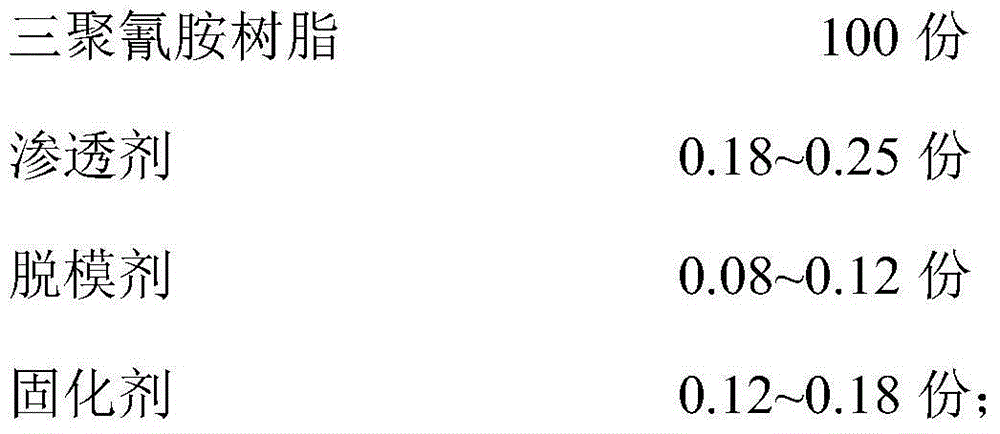

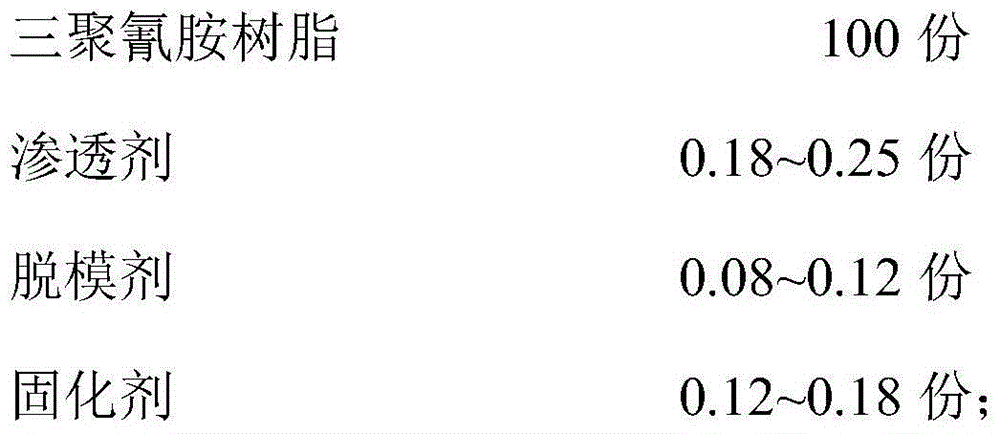

[0030] (1) Glue compounding: melamine resin 100kg, penetrant 0.2kg, release agent 0.1kg, curing agent 0.15kg, mix and stir well, 100℃ water-soluble curing time 6-8min...

Embodiment 2

[0036] 1. Preparation of melamine resin:

[0037] (4) drop the water of 100kg of formaldehyde and 45kg in the reactor, add the modifying agent of 8.5kg, stir;

[0038] (5) 75kg of melamine is dropped into the reactor, and the temperature is raised to 94-96°C for 90min at a rate of 1.5°C / min;

[0039] (6) When the volume ratio of the resin to water is detected to be 1:2.0-2.5 at 25°C, the temperature is lowered to 40°C and discharged to obtain the melamine resin.

[0040] The parameters of the prepared melamine resin are as follows: the viscosity is 0.30-0.34Pa·s, the water ratio is 1:1.3-1.5, and the density is 1.17-1.18g / cm 3 , solid content of 44 to 46%.

[0041] 2. Preparation of environmentally friendly surface adhesive film paper

[0042] (1) Glue compounding: melamine resin 100kg, penetrant 0.22kg, release agent 0.11kg, curing agent 0.16kg, mix and stir well, 100°C water-soluble curing time 6-8min, prepared environment-friendly surface film dry pressing resin Used to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com