Water soluble friction reducer used for thick oil well and preparation method thereof

A water-soluble and drag-reducing agent technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of safety hazards, non-flammability of water-soluble drag-reducing agents, low flash point, etc., to increase production, The effect of reducing production costs and prolonging pump life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1: The weight ratio of raw material components of water-soluble drag reducer for heavy oil wells is: fatty acid polyoxyethylene (9) ester: 6%; polyoxypropylene polyoxyethylene propylene glycol ether: 28%; FC-N01 fluorocarbon surfactant : 0.05%; polyether polyol type SAA: 7%; water: 58.95%.

[0038] Preparation process: Add fatty acid polyoxyethylene (9) ester, polyoxypropylene polyoxyethylene propylene glycol ether, polyether polyol type SAA, FC-N01 fluorocarbon surfactant and other four raw materials into the normal pressure enamel reaction kettle in proportion. Slowly raise the temperature to 90°C. Water was added with constant stirring, and after stirring was continued for 30 minutes, the heating was stopped. Stir while cooling, and cool to room temperature. After stirring for 25 minutes, the material is discharged to obtain a water-soluble drag reducer for heavy oil wells.

[0039] Evaluation:

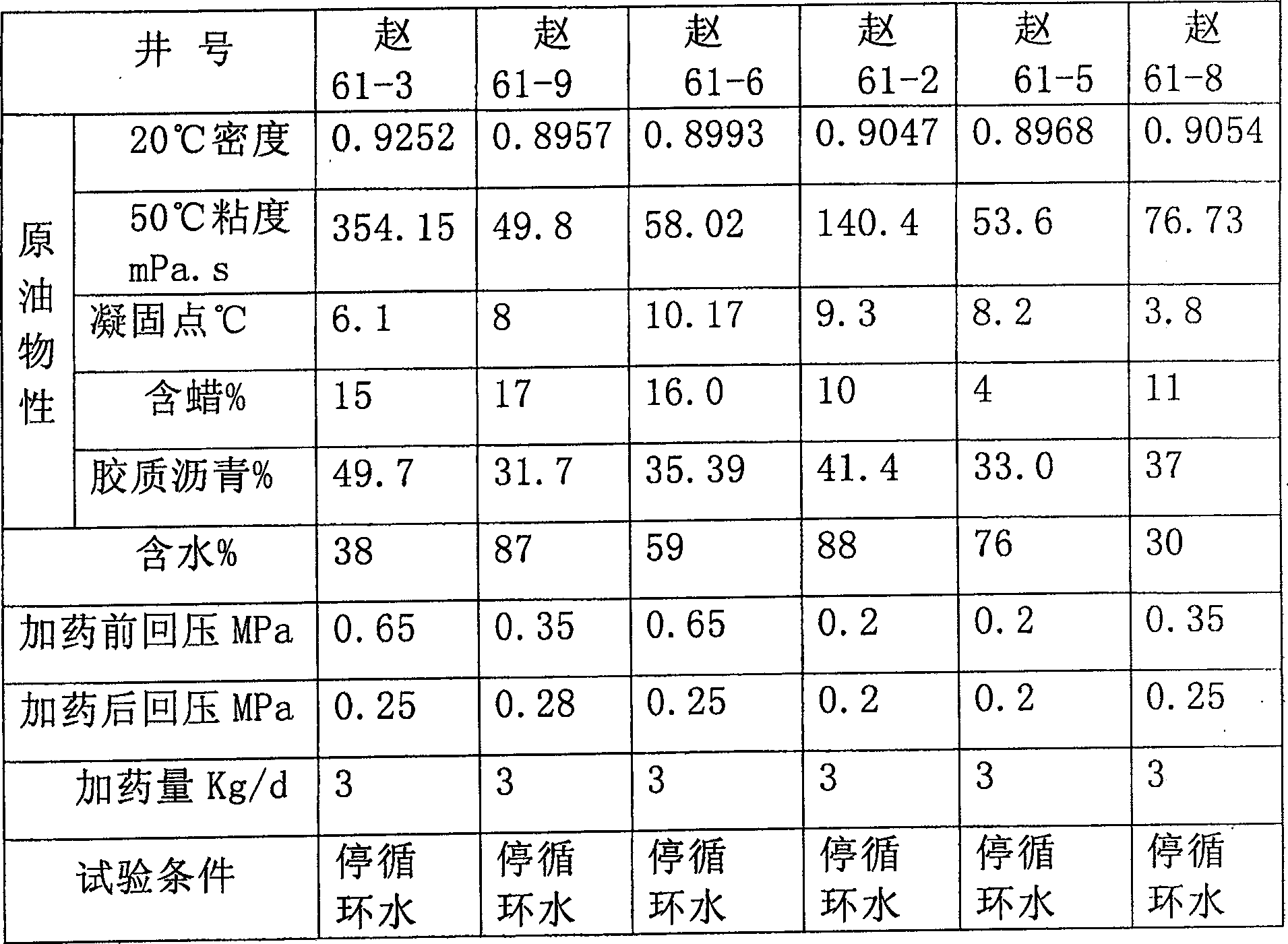

[0040] Zhao 61-3, Zhao 61-6, Zhao 61-9, Zhao 61-2, and Z...

Embodiment 2

[0042] Embodiment 2: The weight ratio of the raw material components of the water-soluble drag reducer for heavy oil wells is: fatty acid polyoxyethylene (9) ester: 6%; polyoxypropylene polyoxyethylene propylene glycol ether: 28%; FC-N01 fluorocarbon surfactant : 0.05%; polyether polyol type SAA: 7%; water: 58.95%.

[0043] The preparation process is the same as in Example 1.

[0044] Evaluation:

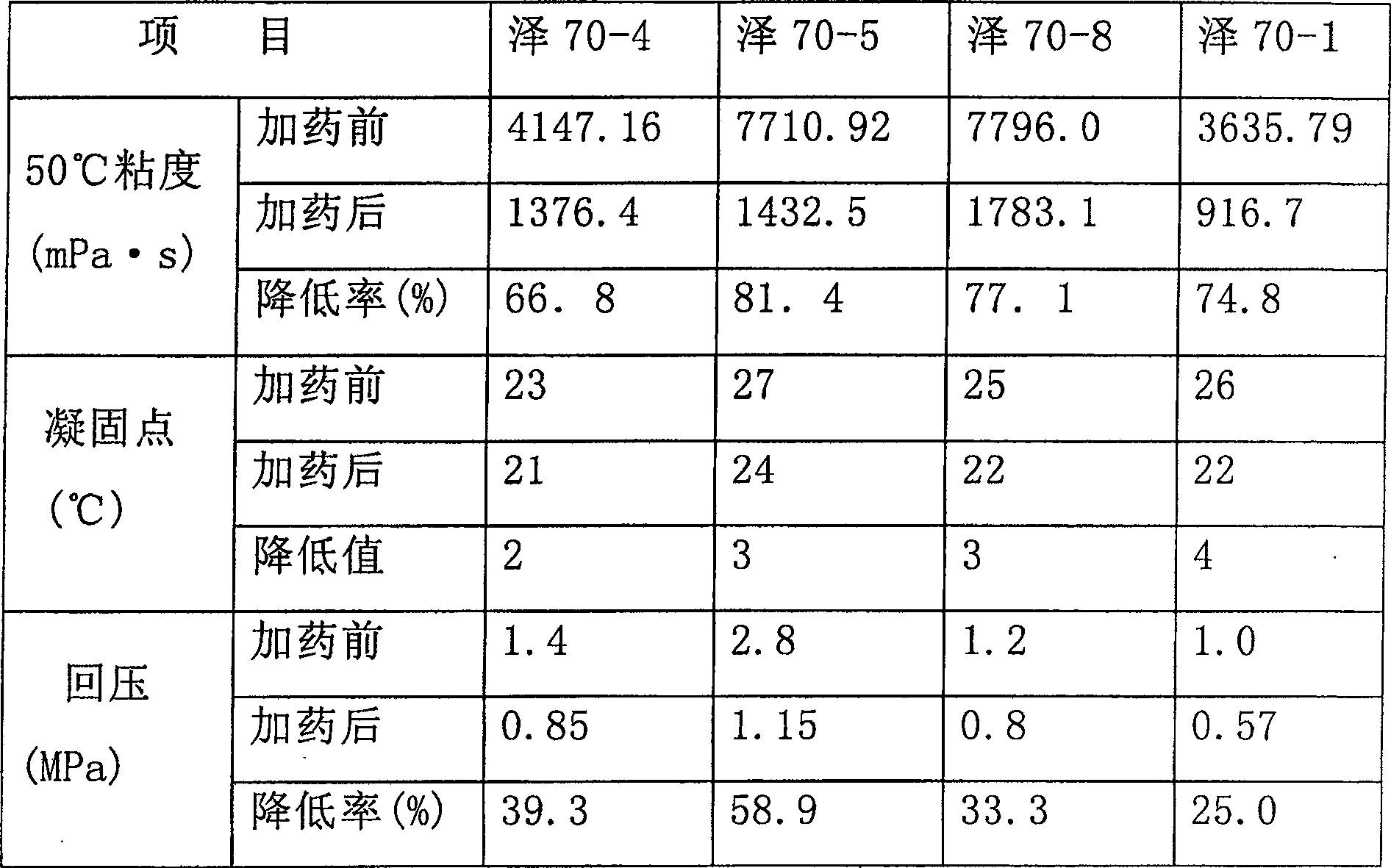

[0045] The water-soluble drag reducer for heavy oil wells is used in the daily maintenance of oil wells in Ze 70 heavy oil reservoirs. When the dosage is 180mg / l, it meets the normal production of oil wells. The effect comparison is as follows:

[0046]

Embodiment 3

[0047] Embodiment 3: the weight ratio of raw material components of water-soluble drag reducer for heavy oil wells is: fatty acid polyoxyethylene (9) ester produced by Shanghai Auxiliary Factory Co., Ltd.: 6%; polyoxypropylene produced by Shandong Binhua Group Co., Ltd. Polyoxyethylene propylene glycol ether: 28%; FC-N01 fluorocarbon surfactant: 0.05%; polyether polyol type SAA produced by Jidong Petroleum Exploration and Development Company: 7%; water: 58.95%.

[0048] The preparation process is the same as in Example 1.

[0049] Evaluation:

[0050] hashtag relatively

density Sticky at 50°C

degree mPa.s freeze

Bitten % first round

key component second level

key component X-10 0.9344 3608.0 55 18.9 48.1 36 24.1 X-12 0.9287 1779.5 41 19.7 41.8 35.3 25.0

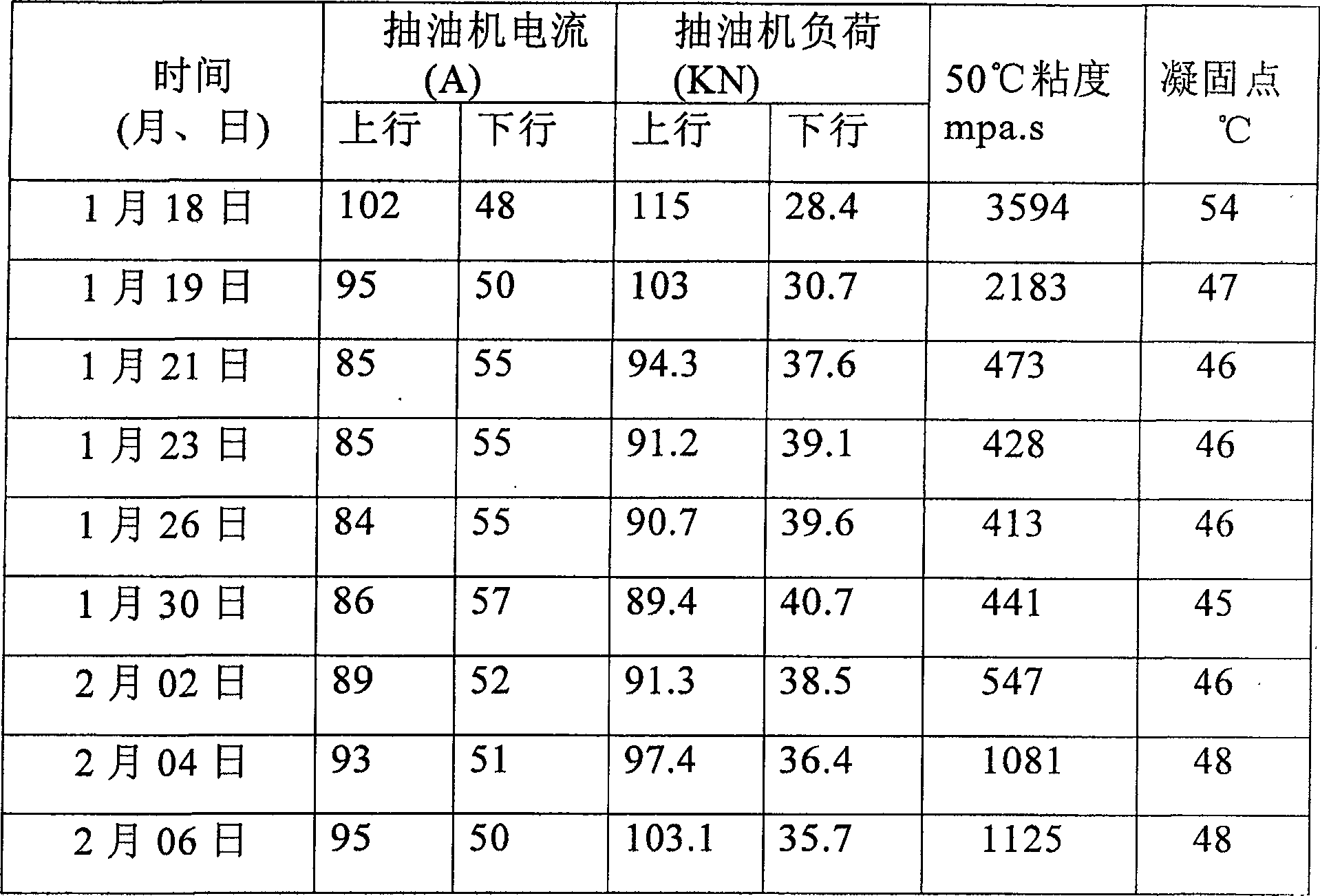

[0051] Well X-10 has not been able to produce normally since it was put into production. After adding water-soluble drag reducer to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com