Pixel structure

A pixel structure and pixel technology, applied in optics, instruments, electrical components, etc., can solve problems such as image retention, unequal area ratio, and different degrees of color shift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

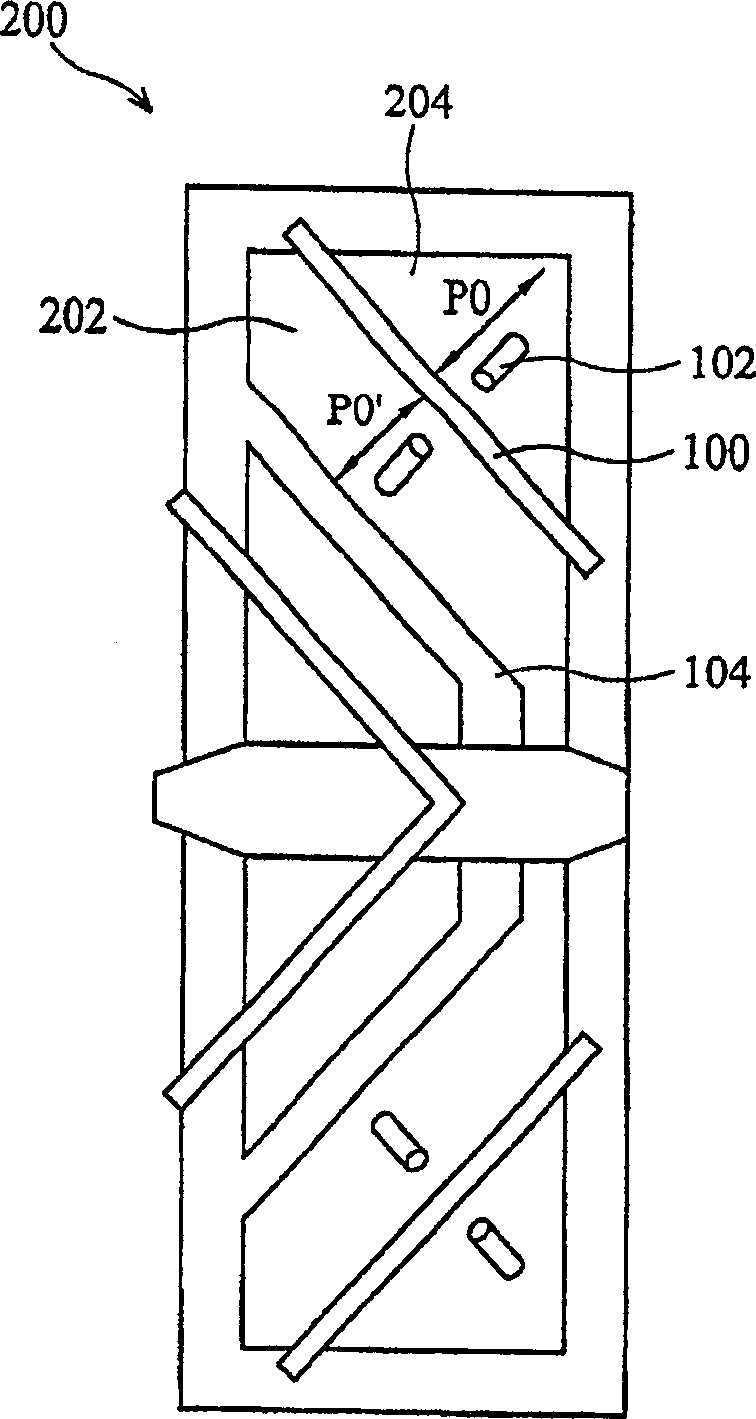

[0061] Figure 5 and Image 6 The first embodiment of the present invention is a schematic diagram showing the sub-pixel structure of a multi-block vertically aligned liquid crystal display, please refer to Figure 4 . In this embodiment, the sub-pixel 1000 includes a color filter substrate 400 and an array substrate 500, and the liquid crystal layer 600 is disposed between the color filter substrate 400 and the array substrate 500; wherein, the color filter substrate 400 includes a first The pretilt angle control structure 410, the array substrate 500 includes a second pretilt angle control structure 512, the pretilt angle control structure can align the liquid crystal, and the first pretilt angle control structure 410 and the second pretilt angle control structure 512 are arranged in a staggered manner, so as to The sub-pixels are divided into multiple azimuthal angle domains (azimuthal angle domain) 10I, 20I, 30I, 40I, 50II, 60II, 70II, 80II, wherein the angle of the azim...

no. 2 example

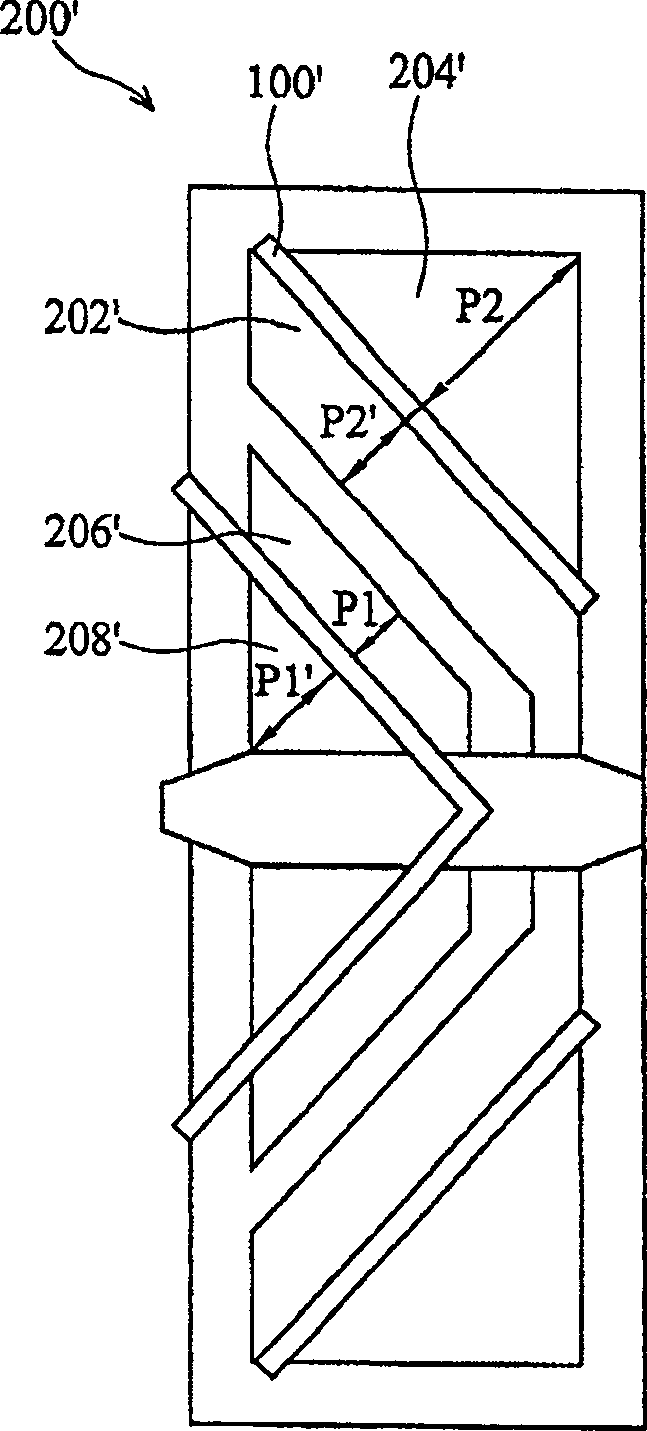

[0072] Figure 7 A top view of an example pixel structure 2000 according to the second embodiment of the present invention is shown. The sub-pixel structure 2000 of this embodiment is similar to the sub-pixel structure 1000 of the first embodiment, but the way of controlling the polar angle block is different. The main difference is that the sub-pixel structure 2000 of this embodiment adds a second thin film transistor 1003', so the sub-pixel 2000 is controlled by the first thin film transistor 1002' and the second thin film transistor 1003'; wherein, the second thin film transistor 1003' includes a second gate 1008', a second source 1023', a second The second drain 1025' and the second channel layer 1009'; the second thin film transistor 1003' is electrically connected to the second corner block II' through the second contact window 1011', and the source electrode 1004' of the first thin film transistor is electrically It is connected to the source 1023' of the second thin f...

no. 3 example

[0075] Please refer to Figure 8 and Figure 9 , the sub-pixel 700 of the third embodiment of the present invention has blocks (polar angle domains) I and II with different polar angles that are symmetrical up and down, and the sub-pixel 700 is separated by a gate 808 or a storage capacitor (Cst) 804 It is the block I of the first polar angle and the block II of the second polar angle, and the pixel electrodes of the block I of the first polar angle and the block II of the second polar angle are discontinuous structures.

[0076] In this example, please refer to Figure 8 , the upper and lower adjacent sub-pixels 700' and sub-pixels 700 have mirrored polar angle blocks I', II', and mirrored azimuth block configurations to achieve the effect of viewing angle compensation, for example, in the sub-pixel 700' : Azimuth block 10II' and 30II' are azimuth 45°, azimuth block 20'II' and 40'II' are azimuth 135°, azimuth block 50I' and block 70'I' are azimuth 225°, azimuth blocks 60I'...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com