Apparatus for making dry cheese

A cheese and equipment technology, applied in cheese substitutes, dairy products, applications, etc., can solve the problems of high price, low degree of automation, and high labor intensity, and achieve the goals of improving measurement accuracy, simple temperature calibration, and reducing labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

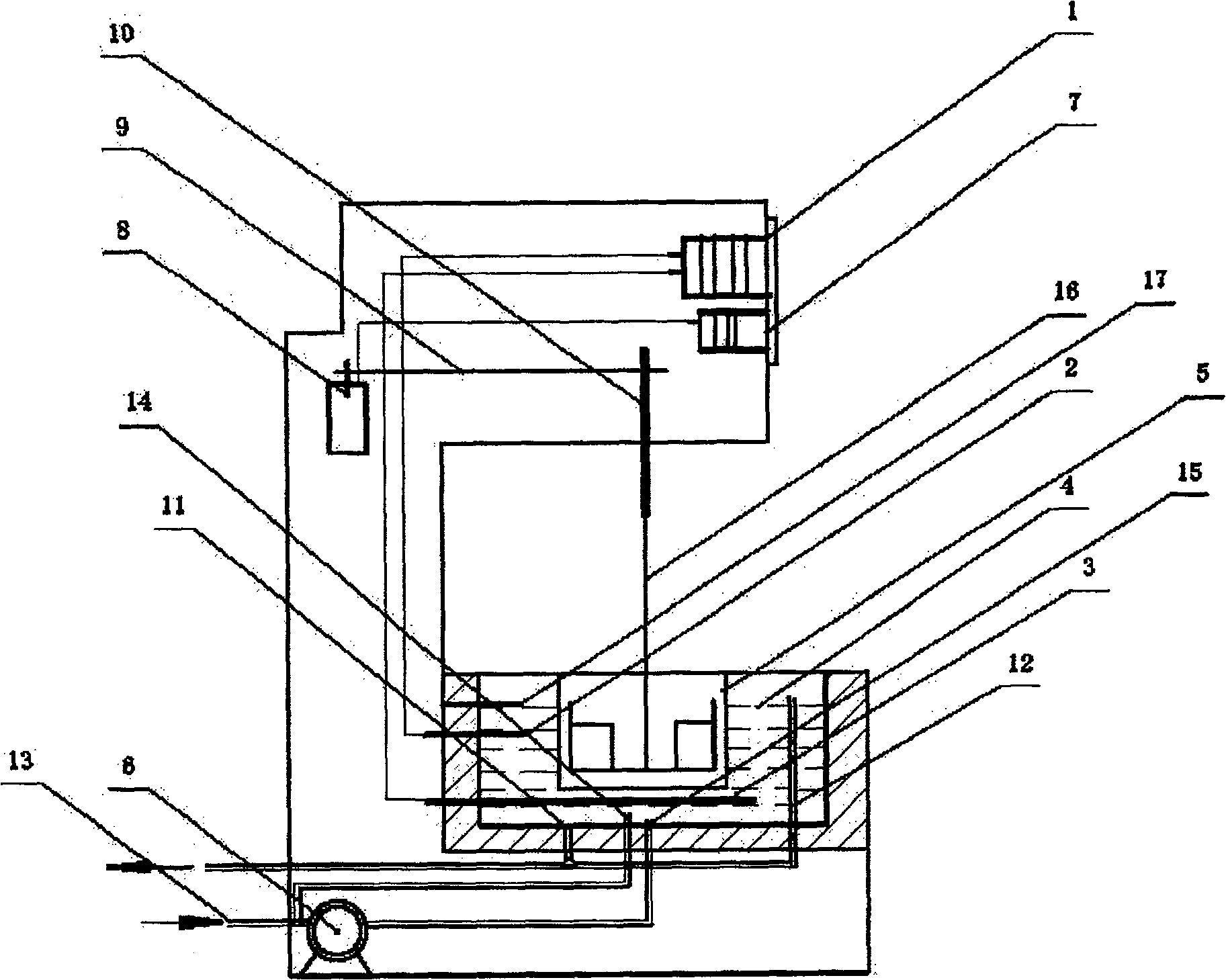

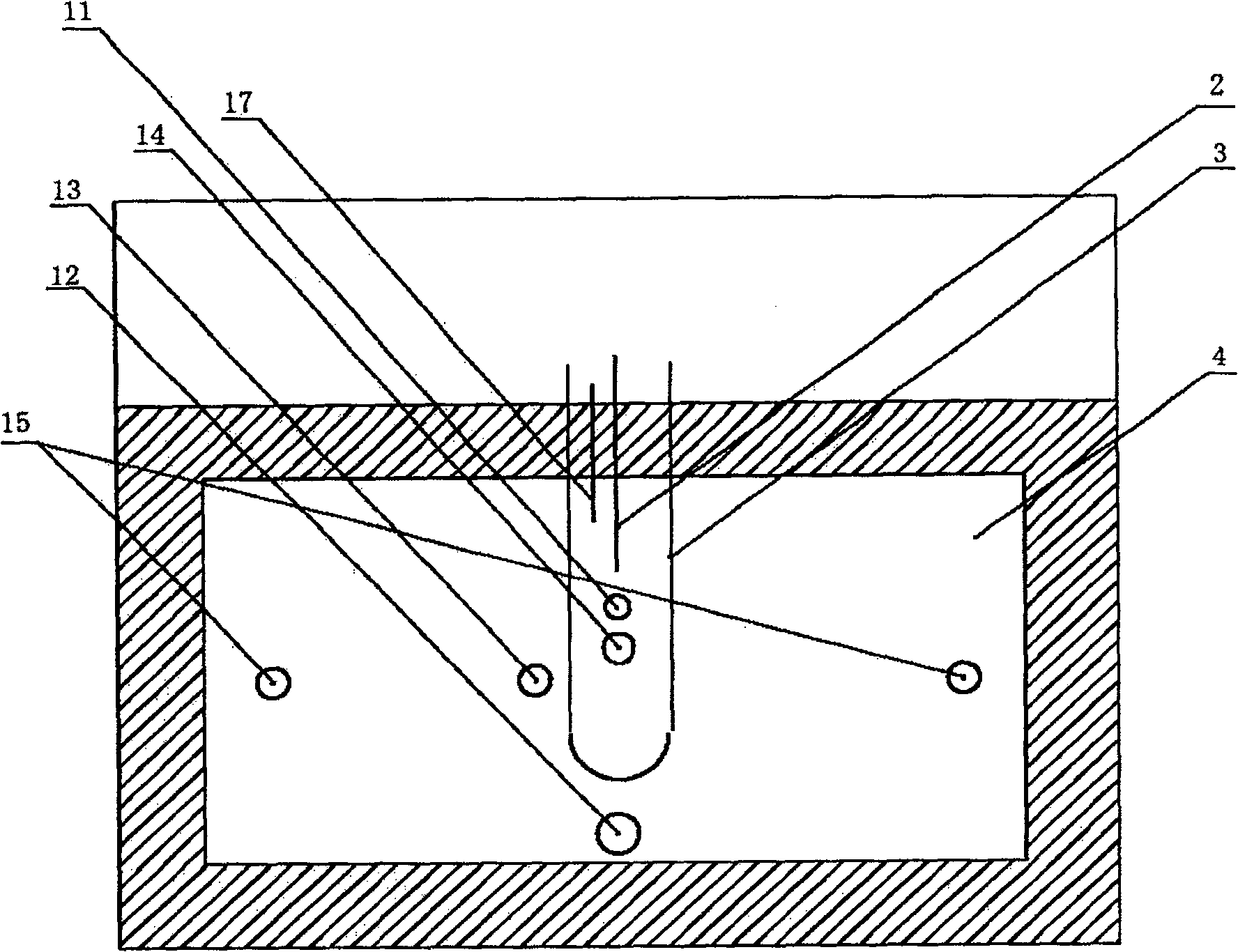

[0029] In the figure: 1 is a program-controlled digital instrument; 2 is a temperature sensor; 3 is an electric heating tube; 4 is a water bath; 5 is a cheese tank; 6 is a water pump; 7 is a speed controller; 8 is a motor; 9 is a transmission chain; 10 11 is an outlet; 12 is an overflow pipe; 13 is a water inlet pipe; 14 is a circulating water inlet; 15 is a circulating water outlet; 16 is a stirring device; 17 is a water level switch.

[0030] see figure 1 and figure 2 , the equipment for producing cheese according to the present invention includes a water bath box 4 and a cheese tank 5 located in the water bath box 4 . There are two cheese tanks 5, each cheese tank 5 is provided with a stirring device 16 driven by a motor 8, an electric heating tube 3 connected with a program-controlled digital instrument 1 is provided in the water bath, and a A water level switch 17 and a temperature sensor 2 connected with the program-controlled digital instrument 1 are used to automati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com