Hollow blocks for building

A hollow block and construction technology, applied in the direction of buildings, building components, building structures, etc., can solve the problems of inconvenient layout, crossing pipelines, inconvenient configuration of longitudinal steel bars, leakage of water to the inner wall, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

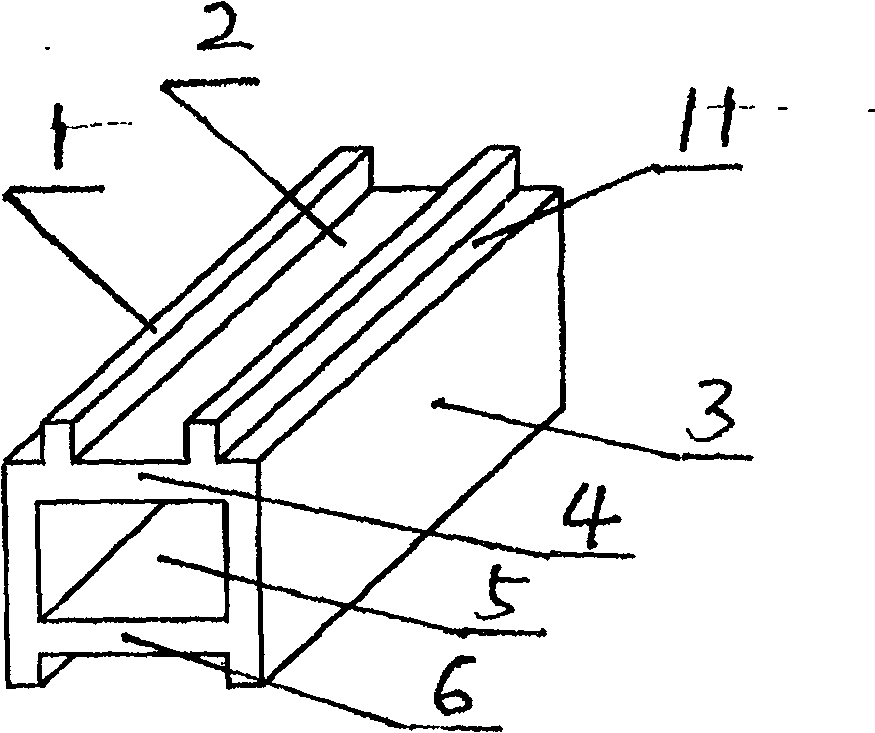

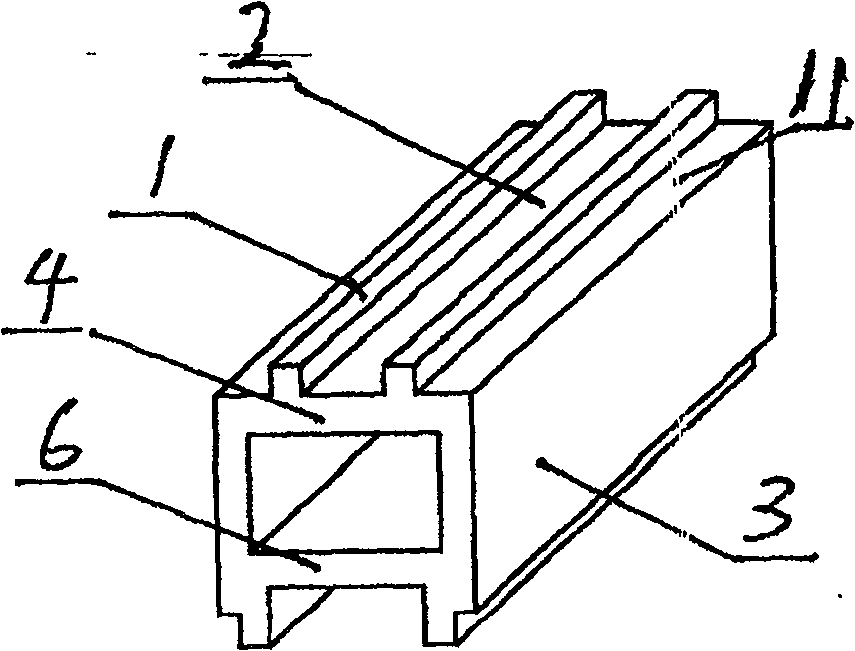

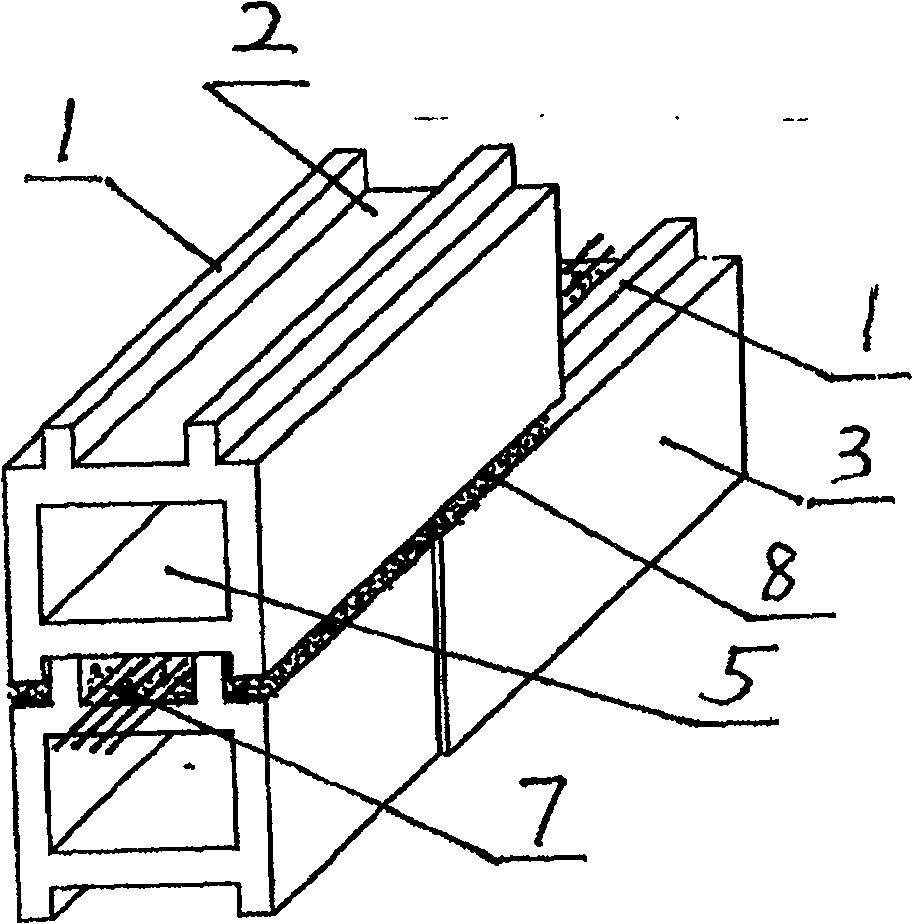

[0013] refer to figure 1 —— Figure 7 , the building uses hollow blocks, consisting of a top plate 4 and two supporting legs 3, the top plate 4 is supported by the two supporting legs 3, a reinforcing rib 6 is arranged between the two supporting legs 3, the top plate 4, two supporting legs 3, and reinforcing ribs 6 To form a block space 5 for the periphery, the top plate 4 is provided with a strip-shaped convex rib 1, the width of the strip-shaped gap 11 is adapted to the width of the two supporting legs 3, and the strip-shaped convex rib 1 pairs with the upper two supporting legs 3 The position-limiting function can also prevent water from leaking from the outer wall to the inner wall. The pipeline layout can be carried out in the groove 2 between the two shaped ribs 1 without passing through the block space 5, which is very convenient. Also be convenient to place steel bar 7 in 2, cast concrete, strengthen the body of wall integrality; Capillary action is generated, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com