Plane luminous element and method for manufacturing same

A technology for light-emitting components and manufacturing methods, which is applied in the manufacturing of semiconductor/solid-state devices, electrical components, electroluminescent light sources, etc. Longevity, the effect of improving quantum efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

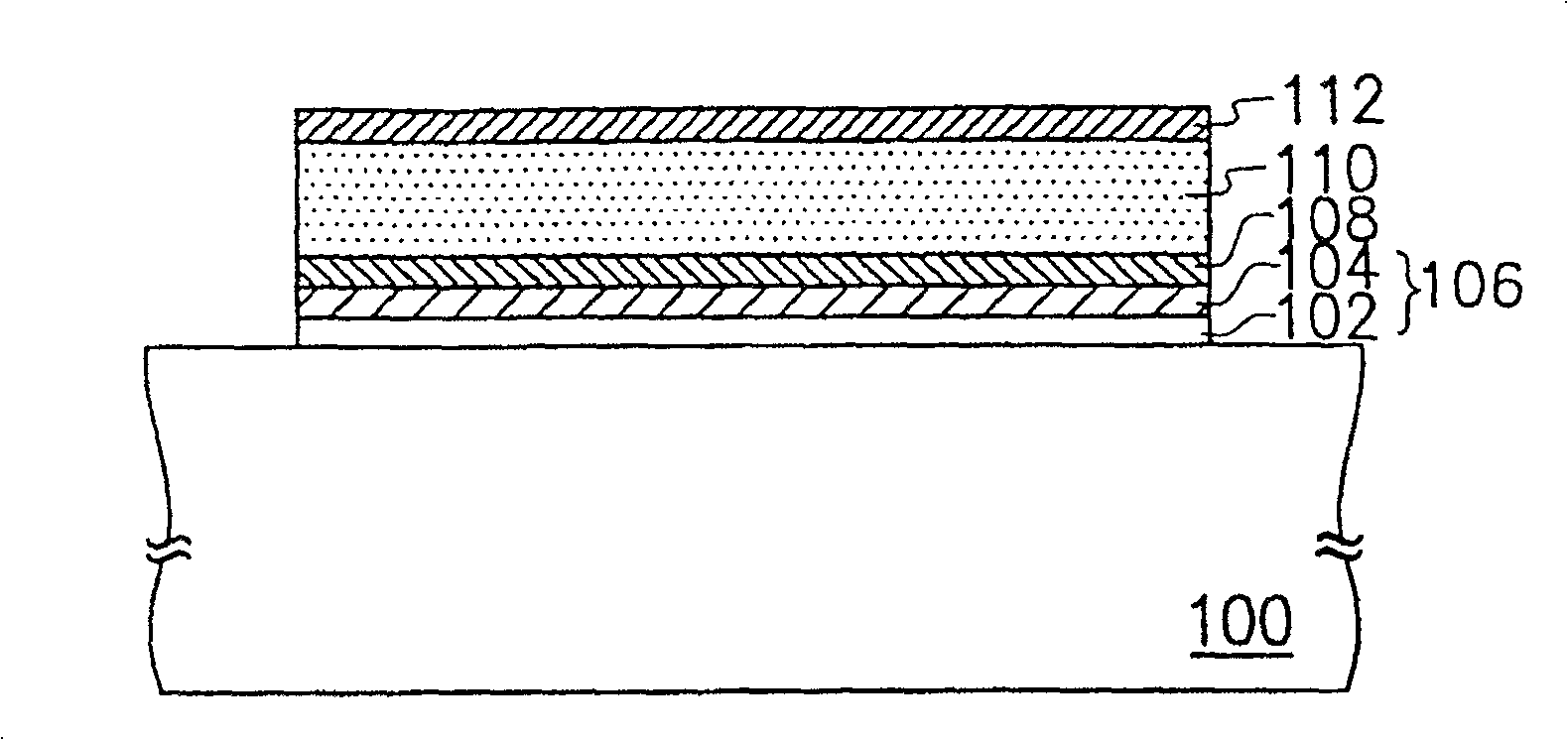

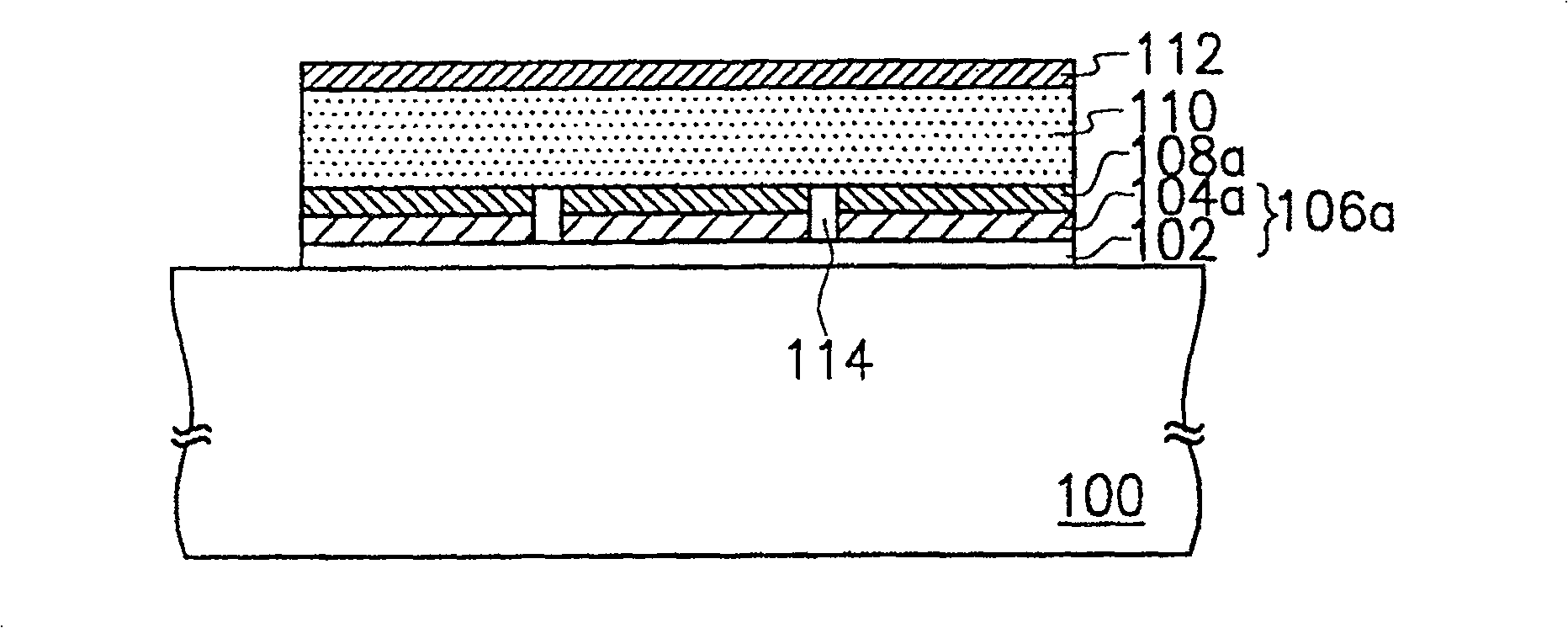

[0034] figure 1 , which is a schematic cross-sectional view of a planar light-emitting device according to a first embodiment of the present invention.

[0035] Please refer to figure 1 , the manufacturing process of the planar light-emitting device of this embodiment is to firstly provide a transparent substrate 100, wherein the transparent substrate 100 can be a plastic substrate or a bendable substrate. Afterwards, a dielectric material layer 102 is formed on the transparent substrate 100 , and a semitransparent metal layer 104 is formed on the dielectric material layer 102 , wherein the dielectric material layer 102 and the semitransparent metal layer 104 form a half lens structure 106 .

[0036] In this embodiment, the method of forming the dielectric material layer 102 is formed by physical vapor deposition or chemical vapor deposition, wherein the physical vapor deposition is, for example, sputtering, evaporation or ion plating. . The material of the dielectric mater...

no. 2 example

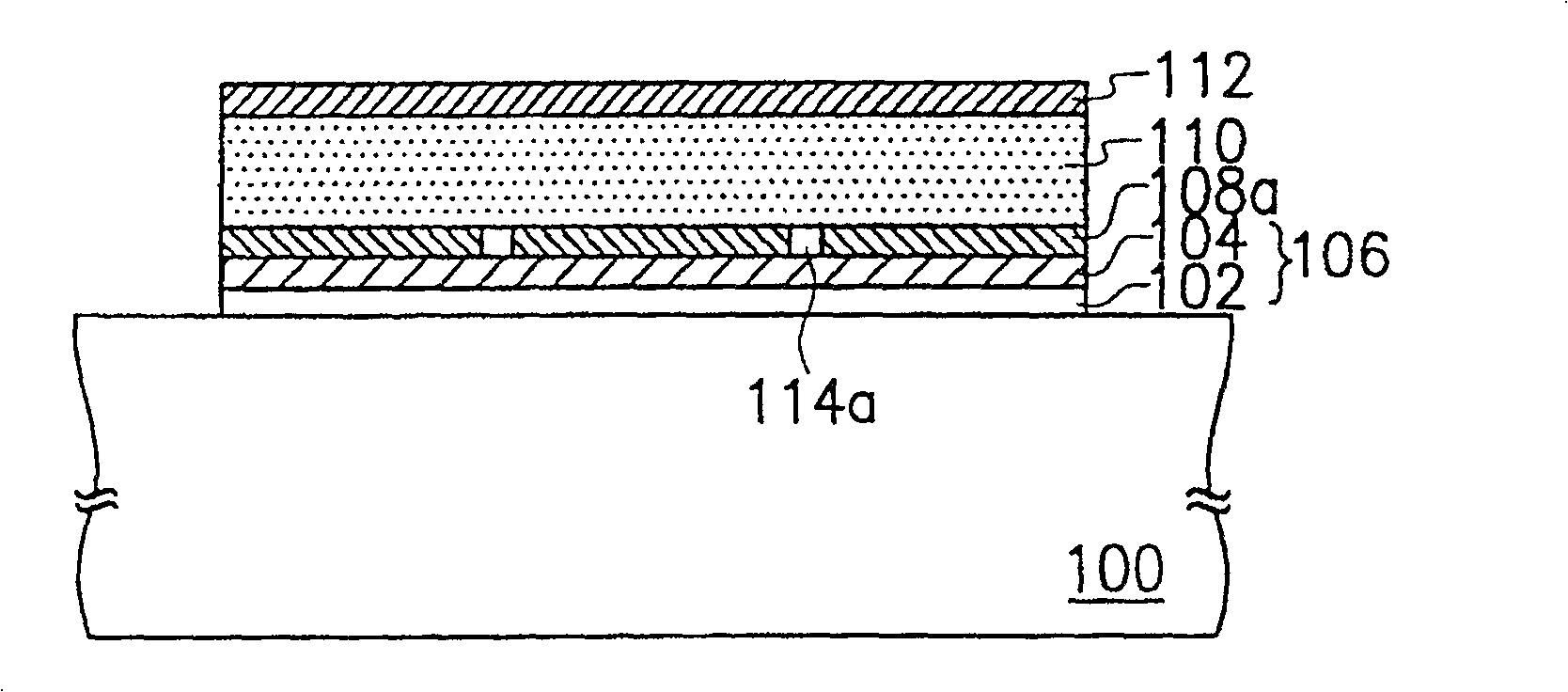

[0051] Figure 7 , which is a schematic cross-sectional view of a planar light-emitting device according to a second embodiment of the present invention.

[0052] Please refer to Figure 7 , the manufacturing process of the planar light-emitting device of this embodiment is to firstly provide a transparent substrate 100, wherein the transparent substrate 100 can be a plastic transparent substrate or a bendable transparent substrate. After that, a dielectric material layer 102 is formed on the transparent substrate 100, and a semi-transparent metal layer 104 is formed on the dielectric material layer 102, wherein the semi-transparent metal layer 104 is used as an anode, and the dielectric material layer 102 and the The semi-transparent metal layer simultaneously constitutes the half-lens structure 106 .

[0053] Here, the methods for forming the dielectric material layer 102 and the semi-transparent metal layer 104 as well as their materials and thicknesses have been describe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com