Method for preparing high-curing modified-guar-gum contained aqueous solution

A technology with high solid content and aqueous solution, which is applied in the direction of water repellent addition, inorganic compound addition, paper, etc. It can solve the problems of slow dissolution speed, difficult control of viscosity, high cost, etc., achieve high solid content, low viscosity, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

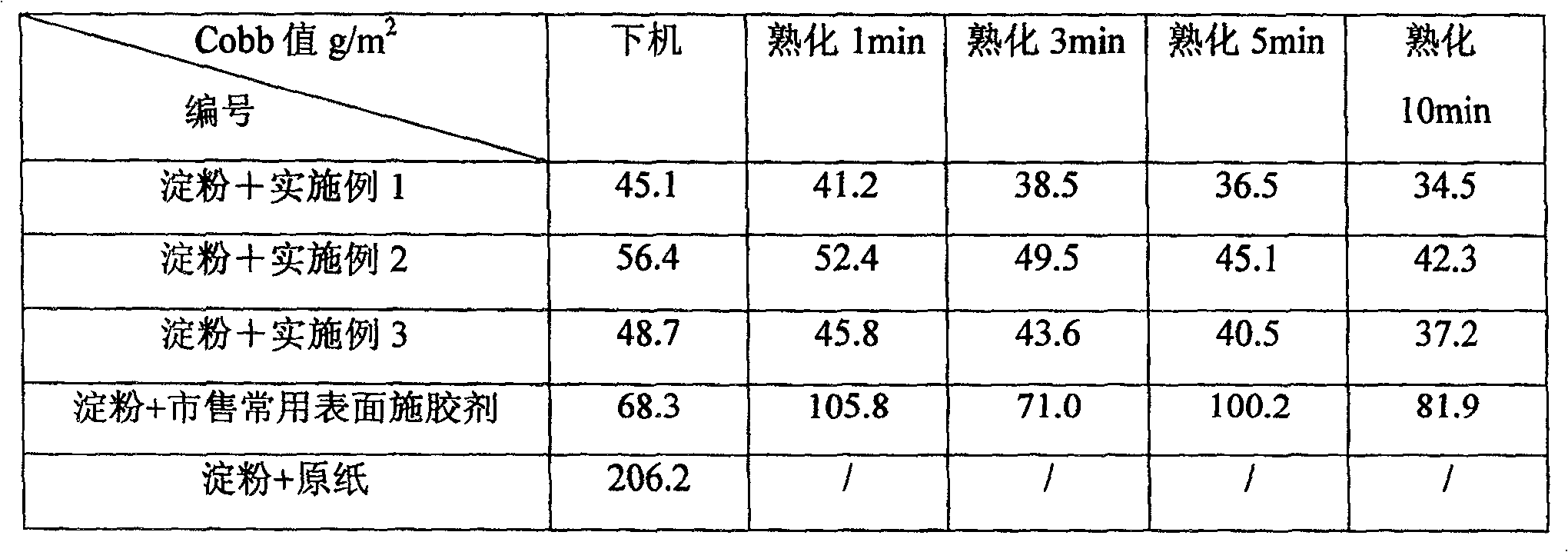

Examples

Embodiment 1

[0025] 82.5 grams of water are added in a 500ml four-necked round-bottomed flask, 15 grams of cationic guar gum powder (water content 10%) are dispersed therein under electric stirring, 5 grams of 5% sodium acetate buffer solution is added, the pH of the system is 7.6, and 10 gram mannase (1000IU / g, solid content is 10%), then add 5 grams (90IU / g, solid content is 10%) galactose oxidase, be warming up to 50 degree of reaction 6 hours under stirring, after Raise the temperature to 90°C and keep it warm for 50 minutes, then cool down to 25°C to obtain a light yellow transparent liquid. The solid content is 11%, the viscosity is 500mpa.s, and the viscosity is measured by NDJ-1 type rotational viscometer according to ISO 2884-2-2003.

[0026] Cationic guar gum powder adopts CG-40, a product of Shanghai Gaowei Chemical Co., Ltd.;

[0027] Mannosidase using PuraBrite from GENENCOR INTERNATIONAL INC. TM , the activity unit is 1000IU / g, and the solid content is 10-12%;

[0028] The...

Embodiment 2

[0030] Add 114 grams of deionized water into a 500ml four-necked round bottom flask, turn on electric stirring, disperse 18 grams of hydroxypropyl guar gum powder (water content 10%) wherein, add 5 grams of 5% calcium acetate buffer solution, the pH of the system is 7 .3, add 15 grams of mannase (1000IU / g, solid content is 10%), then add 20 grams of galactose oxidase (90IU / g, solid content is 10%), be warming up to 40 degrees of reaction under stirring Hours, then raise the temperature to 90°C and keep it warm for 30 minutes, then cool down to 25°C to obtain a light yellow transparent liquid. The solid content is 15.0%, the viscosity is 200mpa.s, and the viscosity is measured by NDJ-1 type rotational viscometer according to ISO 2884-2-2003.

[0031] Hydroxypropyl guar gum is the Jaguar8060 of Rhodesia Company, and other raw materials are with embodiment 1.

Embodiment 3

[0033] Add 110 grams of deionized water into a 500ml four-necked round-bottomed flask, turn on electric stirring, disperse 7 grams of hydroxypropyl guar gum powder and 8 grams of cationic guar gum powder (water content 10%), add 5 grams of 5% phosphoric acid Sodium hydrogen disodium buffer solution, the pH of the system is 7.8, add 10 grams of mannase (1000IU / g, solid content is 10%), then add 5 grams of galactose oxidase (90IU / g, solid content is 10%) , heated to 50 degrees under stirring for 6 hours, then raised to 95 degrees and kept for 10 minutes, and then cooled to below 30 degrees to obtain a light yellow transparent liquid. The solid content is 10.5%, the viscosity is 356mpa.s, and the viscosity is measured by NDJ-1 type rotational viscometer according to ISO 2884-2-2003.

[0034] The source of raw materials is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com