Method and device of line switchover of intelligent distributed frame

A line switching and wiring line technology, applied in the field of electronics, can solve the problems of MEMS matrix hot-switching damage, not providing MEMS matrix, etc., to avoid adhesion and improve reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

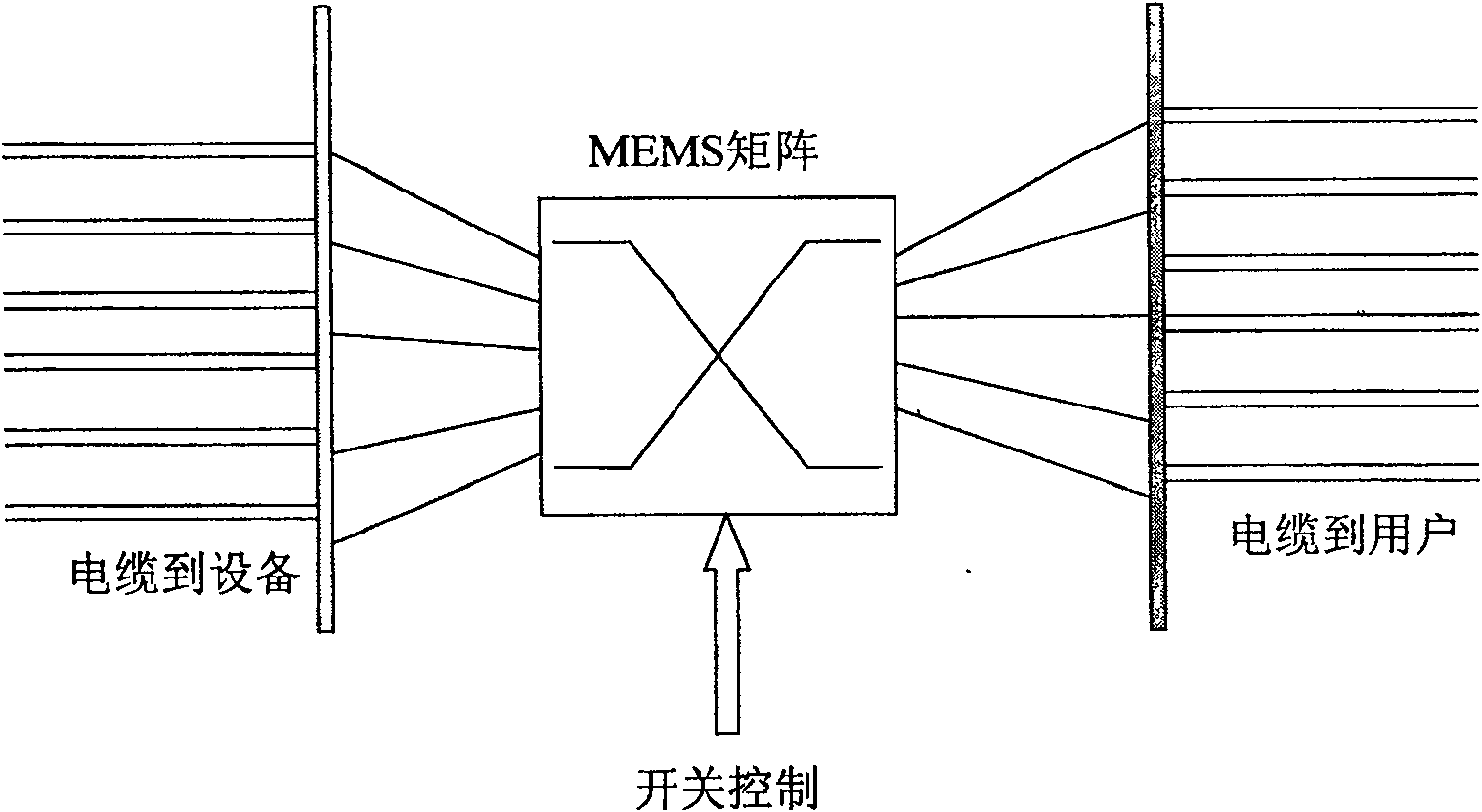

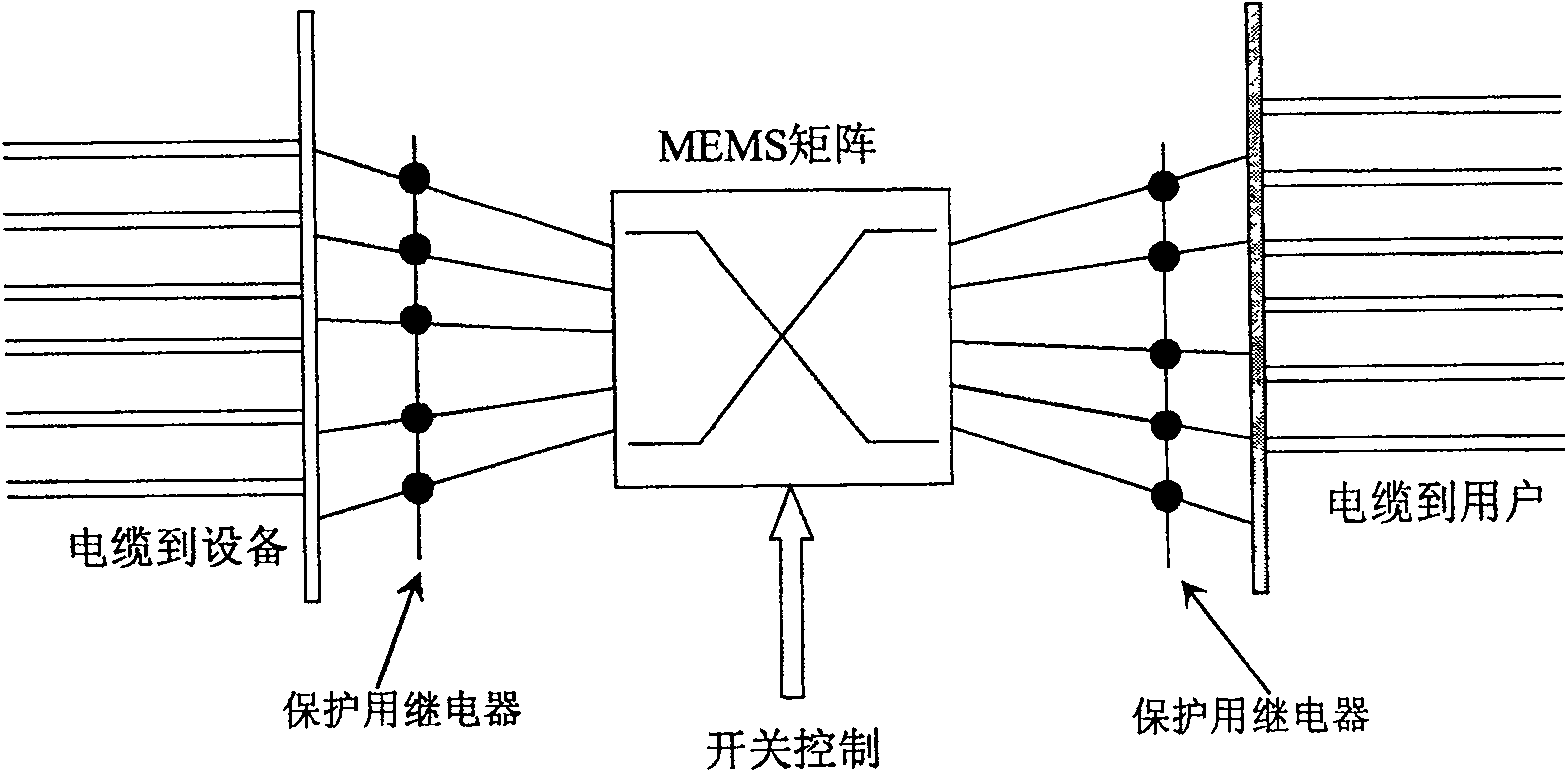

[0034] The core of the present invention is to solve the problem of possible damaged contacts in the MEMS matrix hot switching process. The specific method is to first cut off the current connected to the MEMS matrix when the switching operation is completed. At this time, the current connected to the MEMS matrix is turned on again, so as to avoid the occurrence of the "sticking" phenomenon.

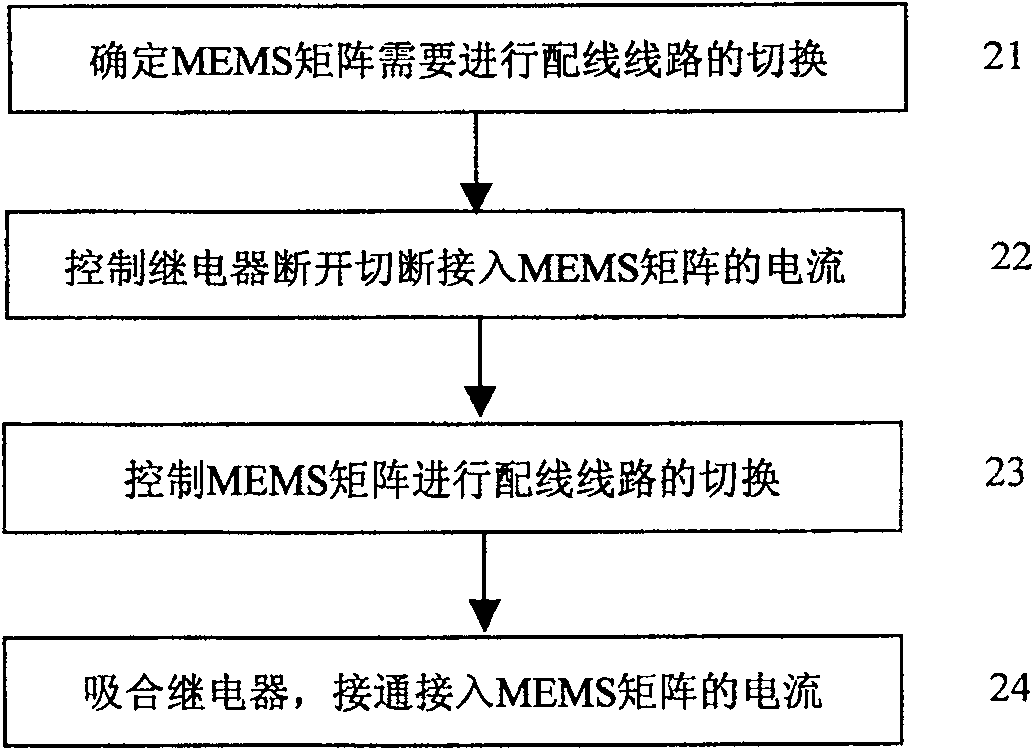

[0035] The present invention firstly provides a method for controlling the switching of matrix lines of MEMS, such as figure 2 As shown, it specifically includes the following steps:

[0036] Step 21: Determine that the MEMS matrix needs to switch the switching unit;

[0037] Step 22: cut off the current connected to the MEMS matrix;

[0038] When it is determined that the switch unit needs to be switched in the MEMS matrix, the access current on both sides of the MEMS matrix needs to be cut off;

[0039] Step 23: The MEMS matrix performs switch unit switching operations to realize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com