Alkaline method for treating black liquor from straw pulp paper-making

A technology of papermaking black liquor and treatment method, which is applied in papermaking, textiles and papermaking, fiber raw material treatment, etc. It can solve the problems of yellow slag increasing process complexity, adding more aluminum sulfate, increasing processing cost, etc., and achieves good separation Practical, small investment, simple equipment and process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] 1. A kind of soda straw pulp papermaking black liquor processing method adopts two steps successively:

[0031] 1) Black liquor treatment:

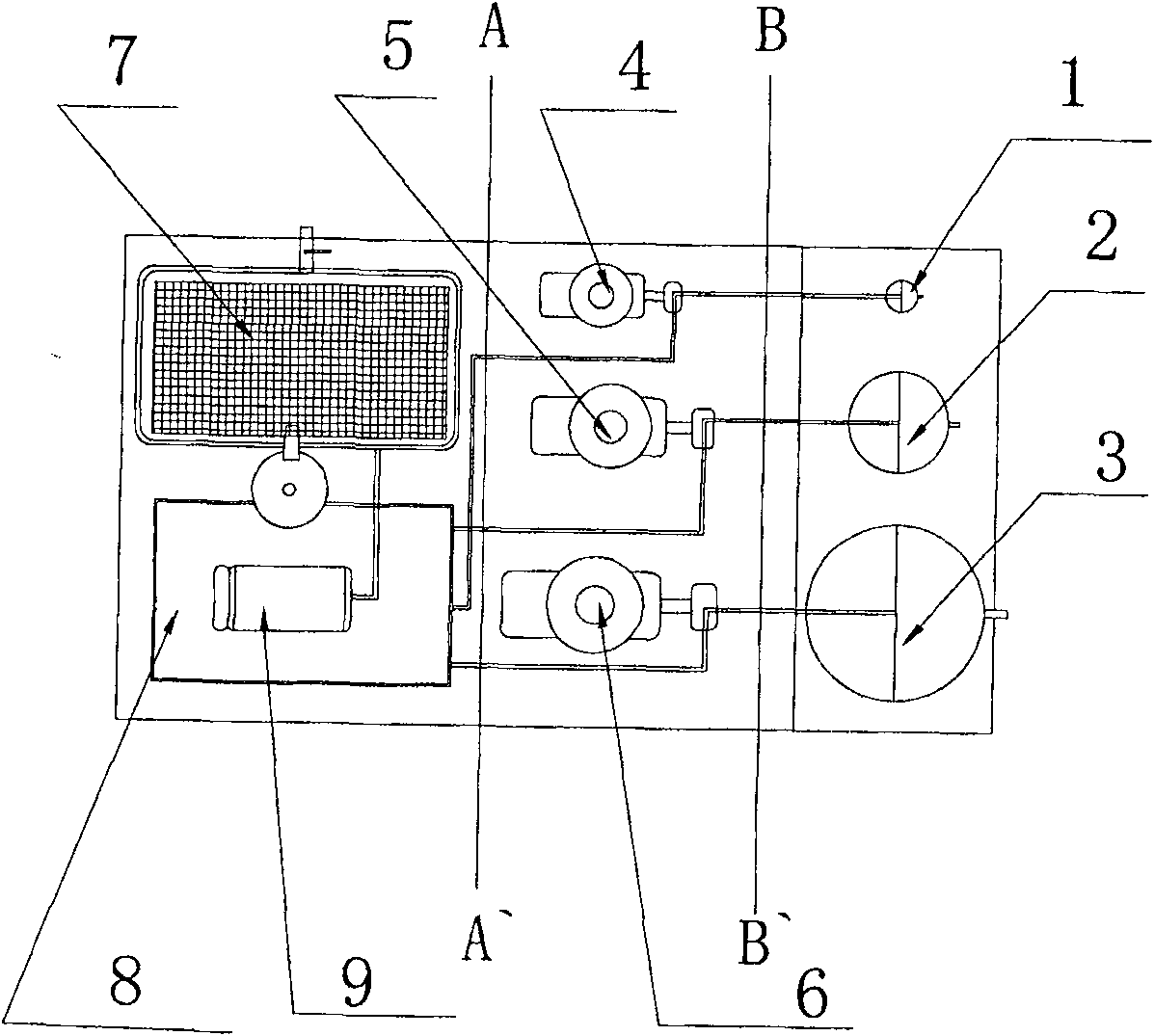

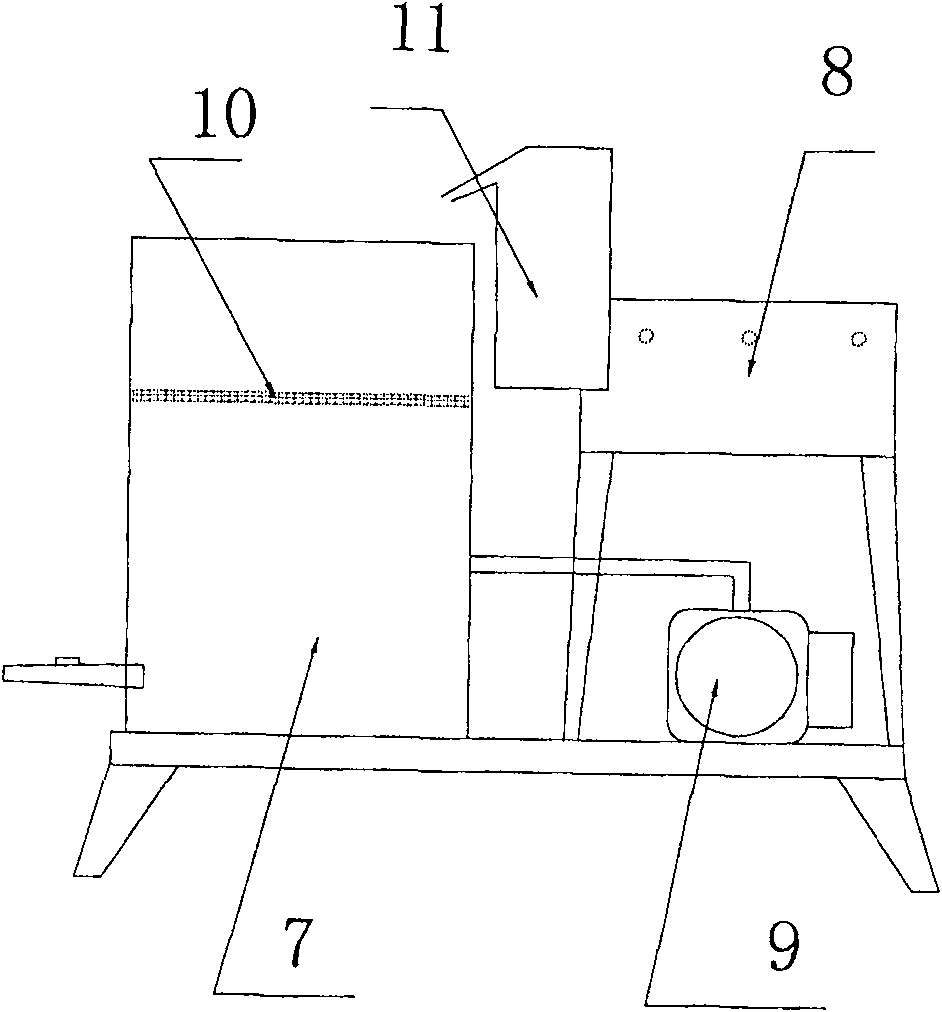

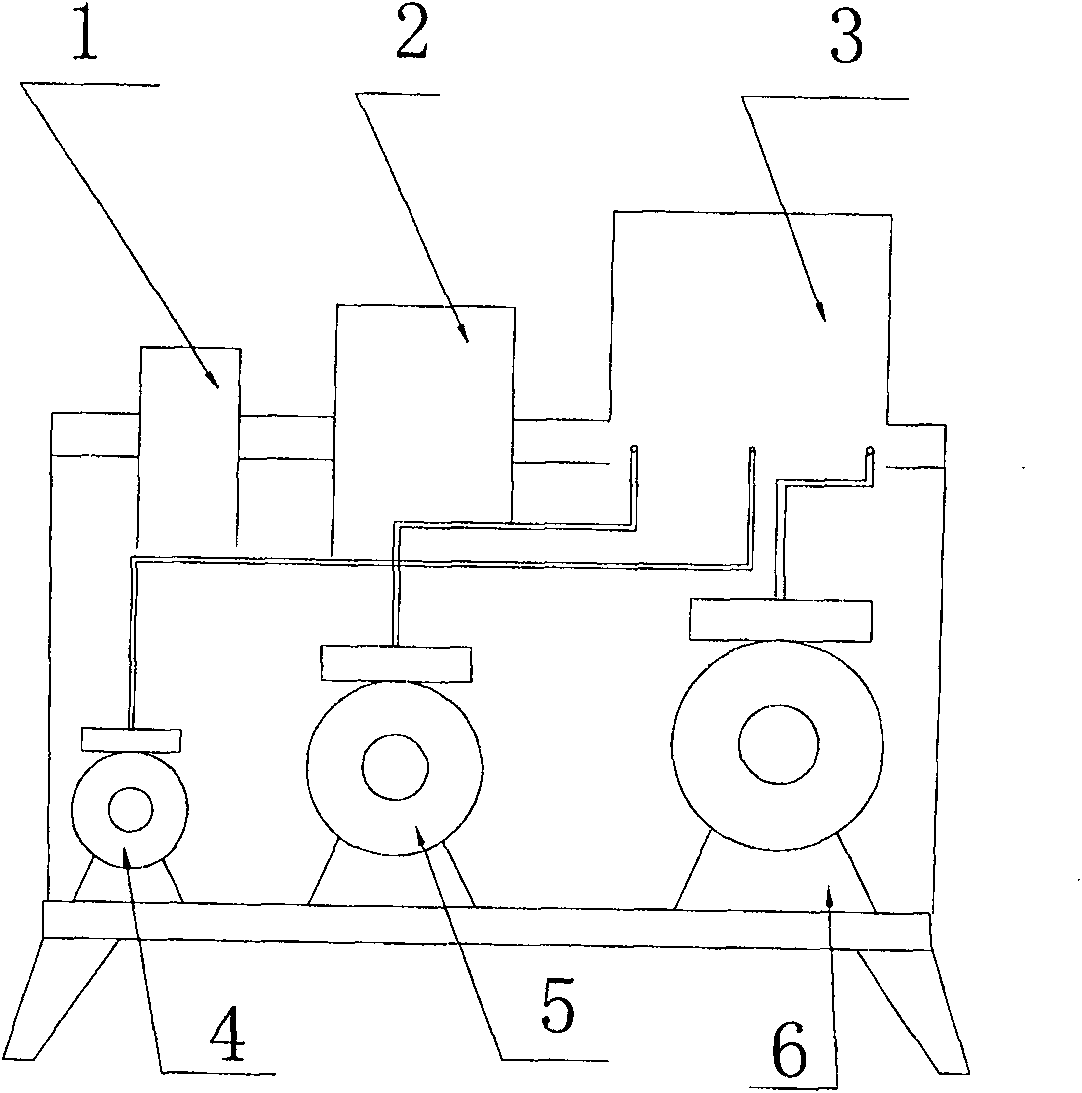

[0032] a. will be 130m 3 COD 120,000 mg / L black liquor is pumped into static mixer 8, 9m from black liquor tank 3 through black liquor pump 6 3 The flocculant is poured into the static mixer 8 from the flocculant tank 1 through the flocculant pump 4, and its flow rate is 0.8 meters per second, and the first half of the length of 4 meters in the passing static mixer is mixed, and the mixing time is 5 seconds. The flocculant is high-molecular polyacrylamide with a molecular weight of 14 million, and the amount added is 10 / 10,000 of the total weight of the black liquor.

[0033] b. The static mixer 8 can allow the two to fully mix, and then mix with the waste sulfuric acid with a concentration of 24% from the dilute acid tank 2 through the dilute acid pump 5 and pass through the second half of the static mixer 8. The length of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com