Concrete pole top protection mining method

A mining method and mining method technology, which is applied in the mining field with concrete pillars to protect the roof, can solve the problems of incomplete recovery of ore, large thickness of ore body, etc., and achieve saving of waste transportation costs, safe mining conditions, and good practical value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

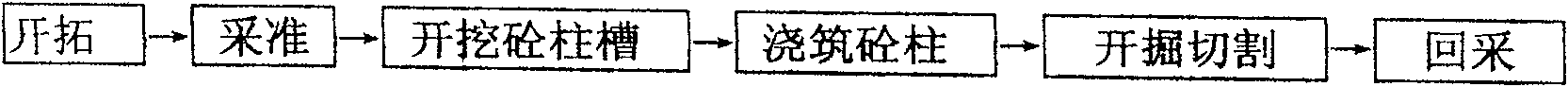

Method used

Image

Examples

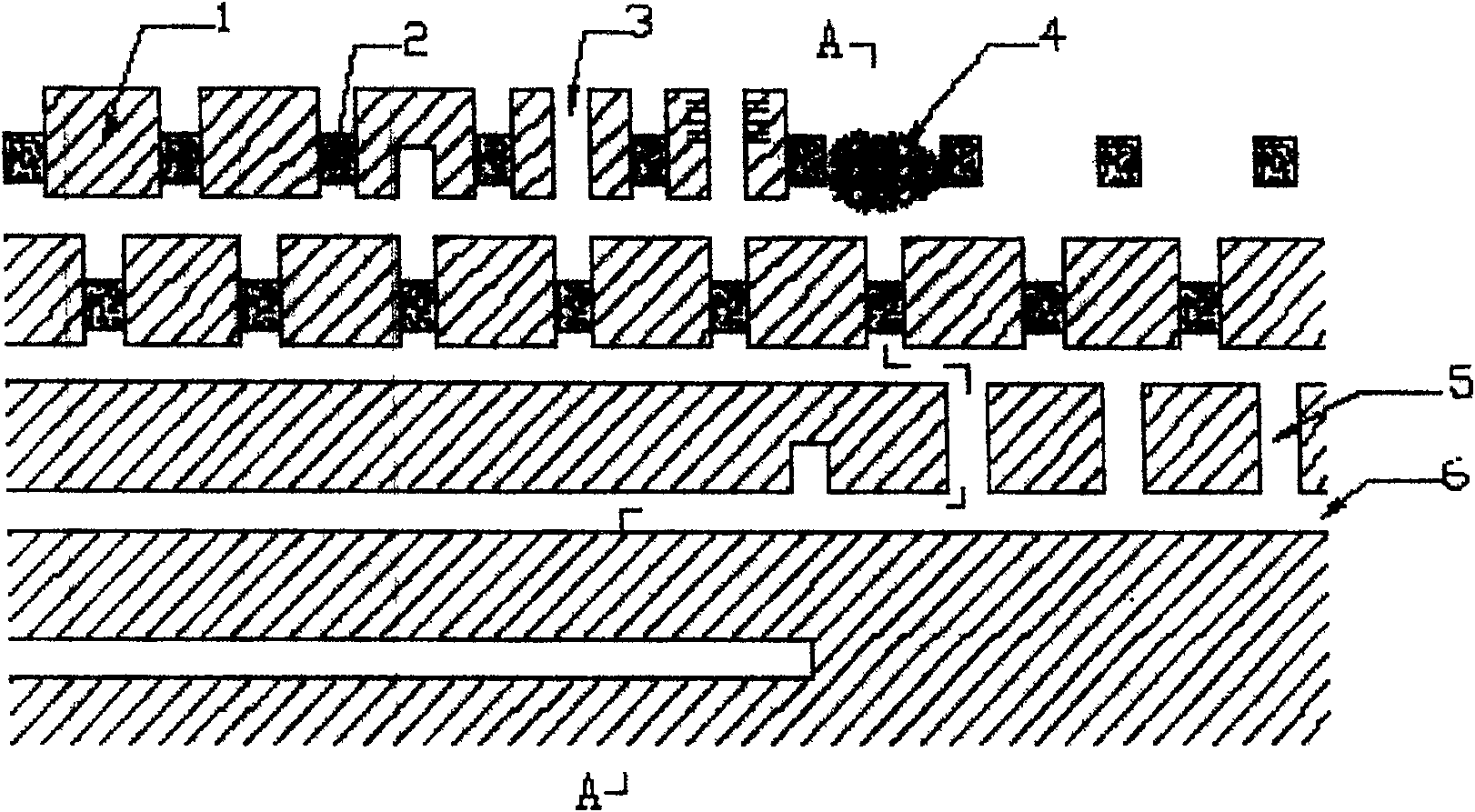

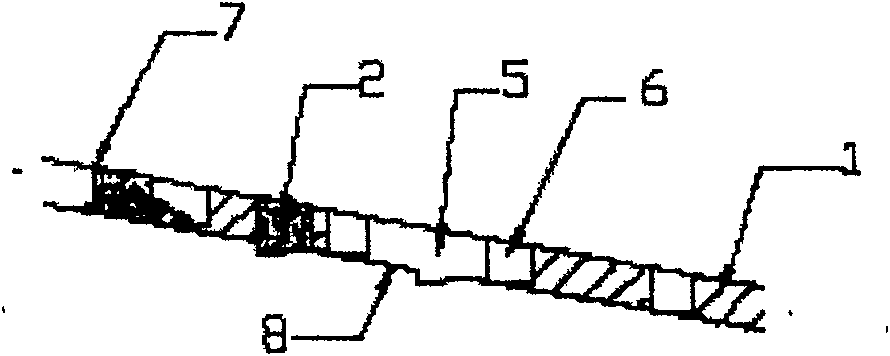

Embodiment

[0023] The basic geological conditions of Guizhou Kailin Group in the northern section of the Jile Mine Section of the Mining Corporation at the level of 824m to 838m and the level of 815m to 824m are: (1) The ore layer (Zbp): mainly dense massive, granular, and fine-grained strips Banded phosphorite, the ore body is stable and layered, with a single structure and brittle ore, with a dip angle of 5°-15° and a thickness of 3-4m. (2) Roof: Direct roof (Zbd3): This layer is also known as "false roof". The lithology is complex and changeable, with mutual defects and extremely unstable. The thickness of this layer is 0-9m, generally 1-4m, very unstable, F=1-4. Indirect roof (Zbdn1): It is the first section of the Dengying Formation, commonly known as "Old Ding", which is gray-white and gray thick-layer fine-grained dolomite, which is 30-35m thick and stable, F=8-10. (3) Floor (Zbd1): The immediate floor of the mine is yellow-gray thin to medium-thick phosphorus-containing sandy do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com