Display

A display device and display device technology, applied in the direction of identification devices, static indicators, instruments, etc., to achieve the effect of improving viewing angle dependence and high display quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

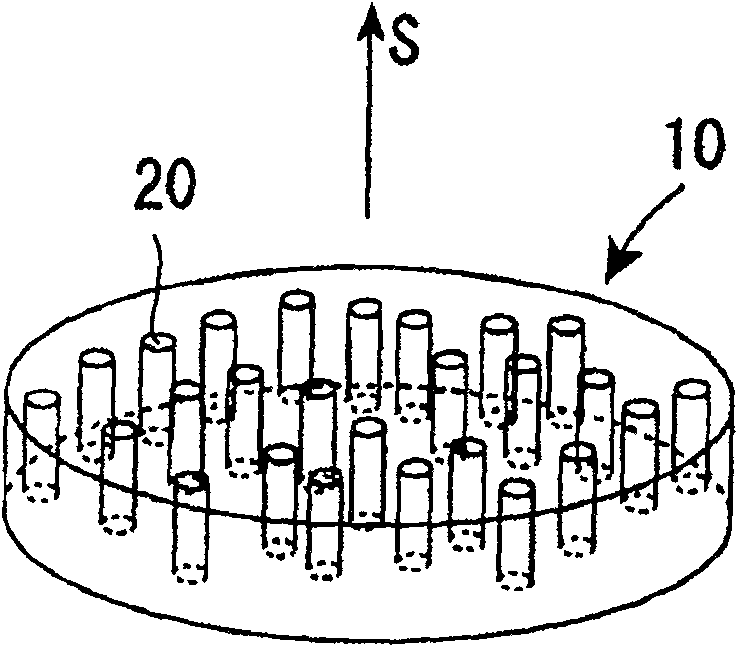

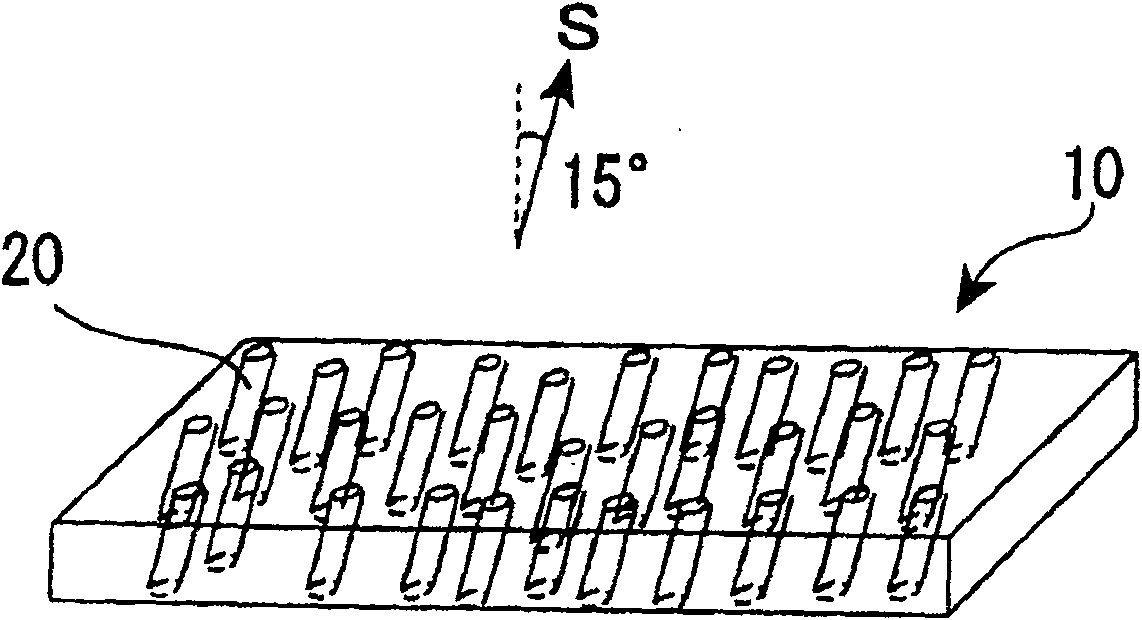

[0117] (Fabrication of the first anisotropic scattering film)

[0118]First, a polyethylene terephthalate (PET) film with a thickness of 75 μm and a size of 76×26 mm (trade name: Cosmosiyain (registered trademark), part number: A4300, manufactured by Toyobo Co., Ltd. ) was ejected from the edge portion of the liquid resin, and then the liquid resin was solidified to form partition walls with a height of 0.2 mm. Next, after dropping the photopolymerizable composition of the following composition into the area|region surrounded by a partition, it covered with another PET film.

[0119] "Composition of Photopolymerizable Composition"

[0120] 2-(perfluorooctyl)-ethyl acrylate 50 parts by weight

[0121] 1,9-nonanediol diacrylate 50 parts by weight

[0122] 2-Hydroxy-2-methyl-1-phenylpropan-1-one 4 parts by weight

[0123] Afterwards, for the liquid film with a thickness of 0.2mm sandwiched by the PET film, it was vertically irradiated for one minute from the reflection irradi...

Embodiment 2

[0138] Figure 7 It is a schematic oblique view showing the configuration of a VA-mode liquid crystal display device 100a according to Embodiment 2 of the present invention. The relative relationship such as the lamination axis direction of each film is as follows: Figure 7 shown.

[0139] First, on the observation surface side of the VA mode liquid crystal cell 11a trial-produced in Example 1, the support film on the side of the VA mode liquid crystal cell 11a was pasted as the second polarizing plate 13b of the second retardation film 12b, and on the backlight side, affixed The support film on the side of the VA-mode liquid crystal cell 11a serves as the third polarizing plate 13c of the third retardation film 12c, and constitutes the VA-mode liquid crystal device 15a. Next, the same first anisotropic scattering film 10a as in Example 1 was bonded to the viewing surface side of the VA-mode liquid crystal display device 15a to constitute the VA-mode liquid crystal display ...

Embodiment 3

[0142] Figure 8 It is a schematic oblique view showing the configuration of a VA-mode liquid crystal display device 100a according to Example 3 of the present invention. The relative relationship such as the lamination axis direction of each film is as follows: Figure 8 shown.

[0143] First, on the backlight side of the VA-mode liquid crystal cell 11a trial-produced in Example 1, the fourth retardation film 12d was pasted, and then the backlight side of the fourth retardation film 12d and the viewing surface side of the VA-mode liquid crystal cell 11a were bonded. The protective film on the side of the VA-mode liquid crystal cell 11a is bonded to the first polarizing plate 13a of a TAC film to form a VA-mode liquid crystal device 15a. Next, the same first anisotropic scattering film 10a as in Example 1 was bonded to the viewing surface side of the VA-mode liquid crystal display device 15a to constitute the VA-mode liquid crystal display device 100a.

[0144] The normal d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com