Cutting insert and cutting tool

A technology for cutting inserts and cutting tools, which is applied in the manufacture of tools, milling cutting inserts, transportation and packaging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

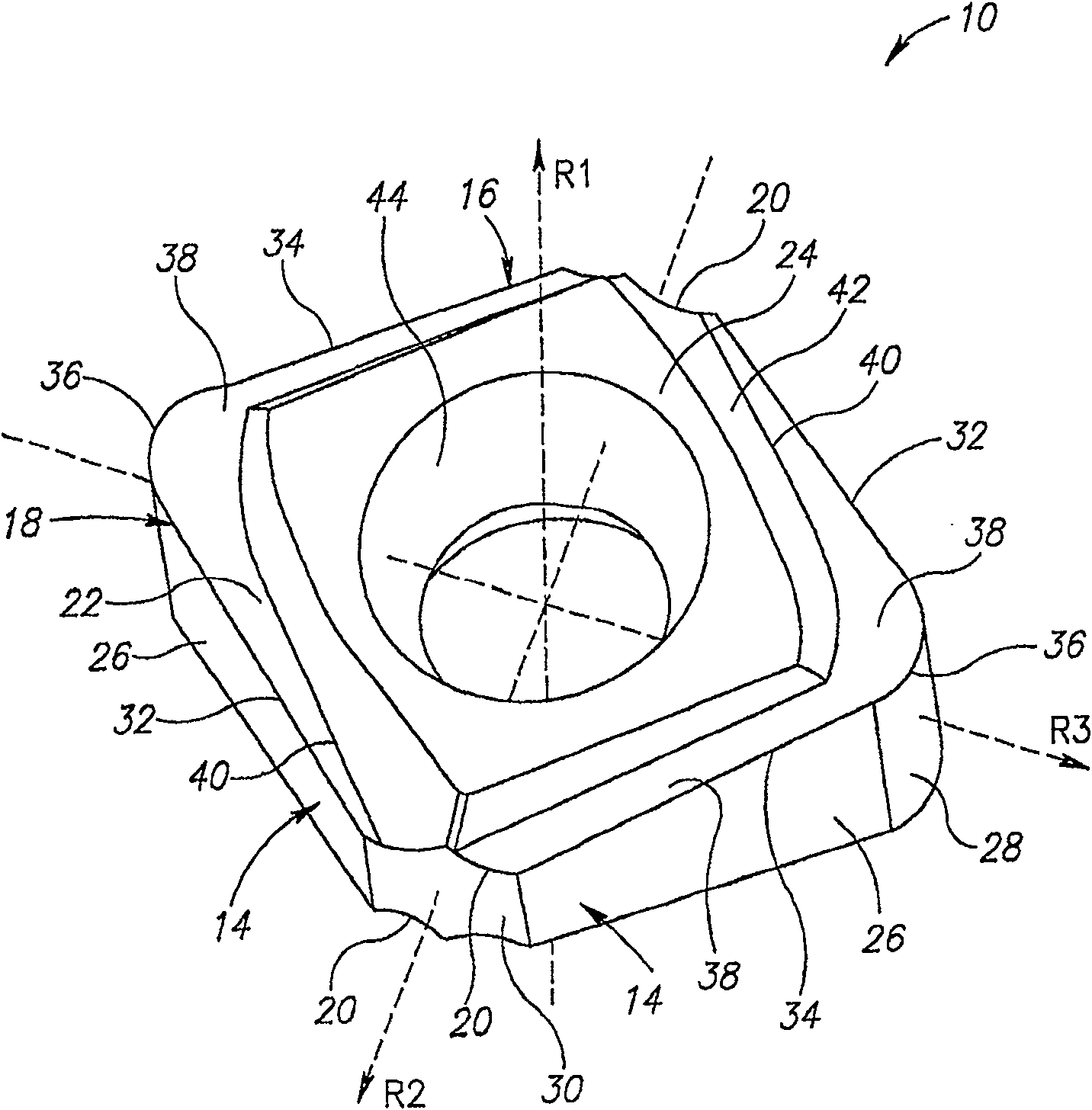

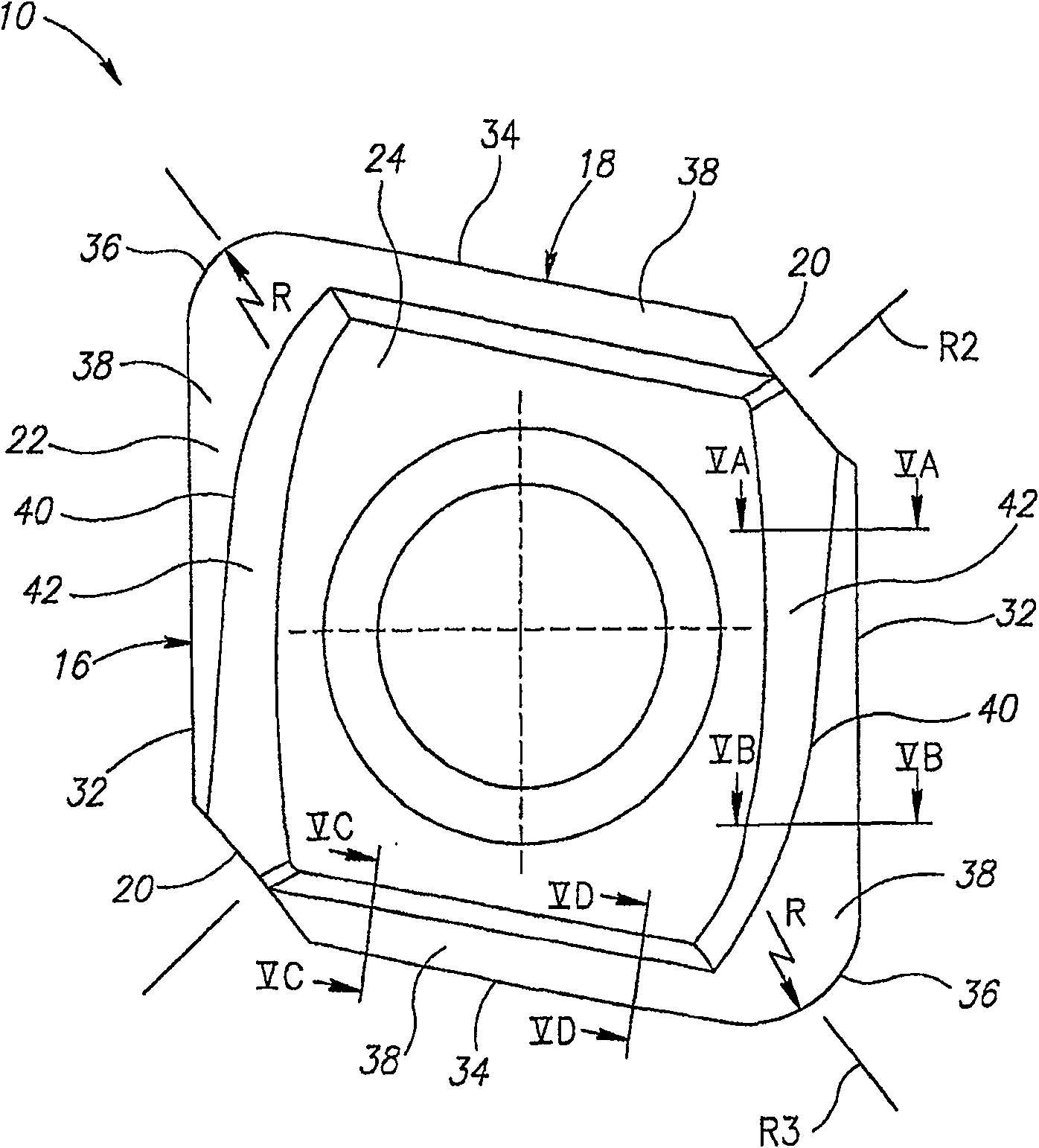

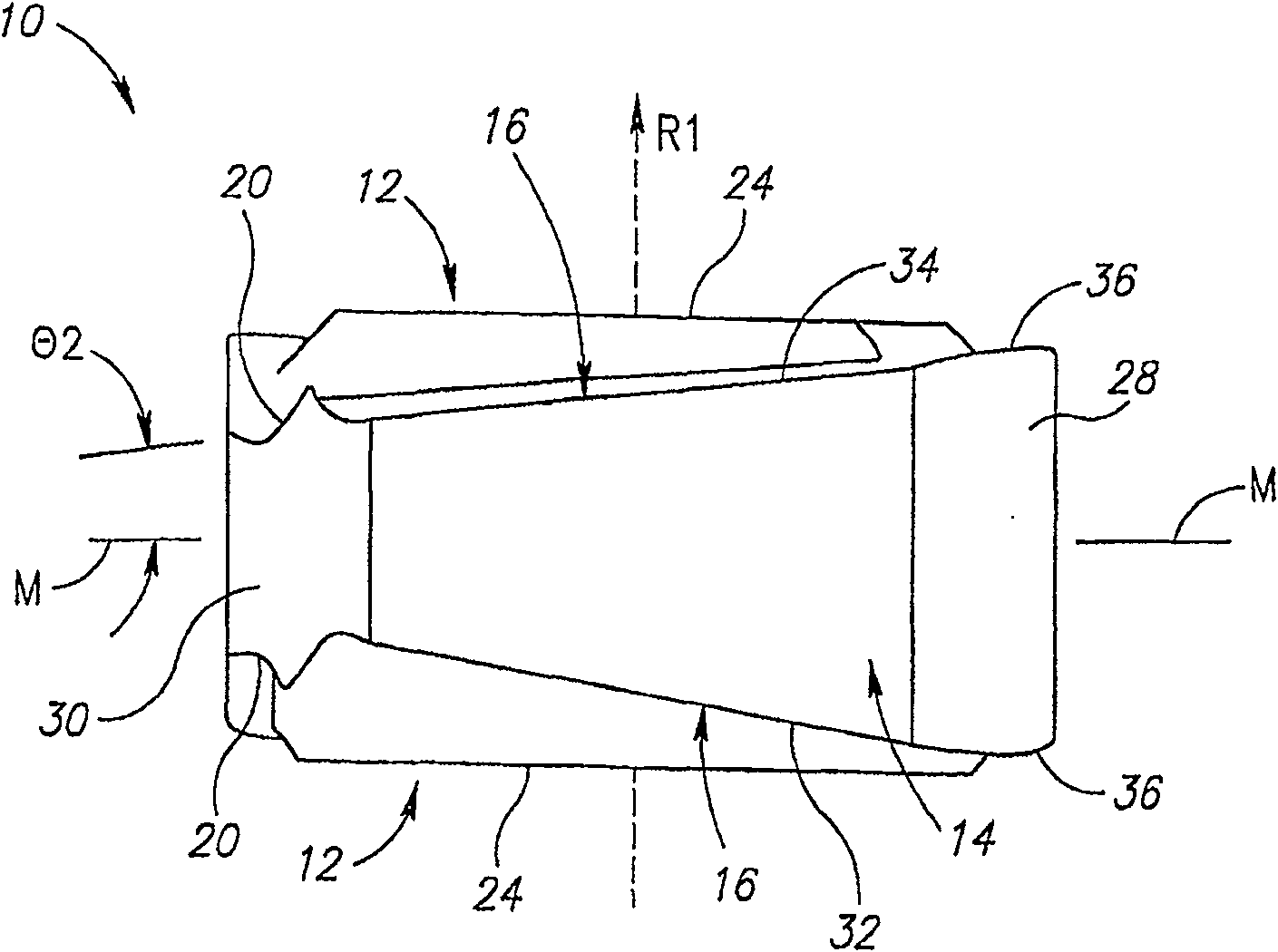

[0036] Reference is first made to the diagram representing an indexable cutting insert 10 according to the present invention. Figure 1-4 . The cutting insert 10 has two identical generally diamond-shaped end surfaces 12 with circumferential side surfaces 14 extending therethrough. Each end surface 12 adjoins a perimeter 16 where the end surface 12 and the circumferential side surface 14 merge. Each perimeter 16 includes two consecutive cutting edge segments 18 separated by two non-cutting edge segments 20 . A groove 22 adjacent a generally planar end region 24 of the end surface 12 adjoins each cutting edge segment 18 . Thus, the cutting insert 10 has two opposing flat end regions 24 . The two opposite flat end regions 24 are parallel to each other and to the plane of symmetry M of the cutting insert 10 in the middle of the flat end regions 24 .

[0037] The circumferential side surface 14 is perpendicular to the plane of symmetry M and includes eight partial side surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com