Audio based rotating machinery vane frequency intelligent test method

A technology of rotating machinery and testing methods, which is applied to the testing of machines/structural components, vibration testing, generation of ultrasonic/sonic/infrasonic waves, etc. It can solve the problems of time-consuming, low precision, and manual judgment of resonance methods, and achieve low cost , high precision, and the effect of suppressing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

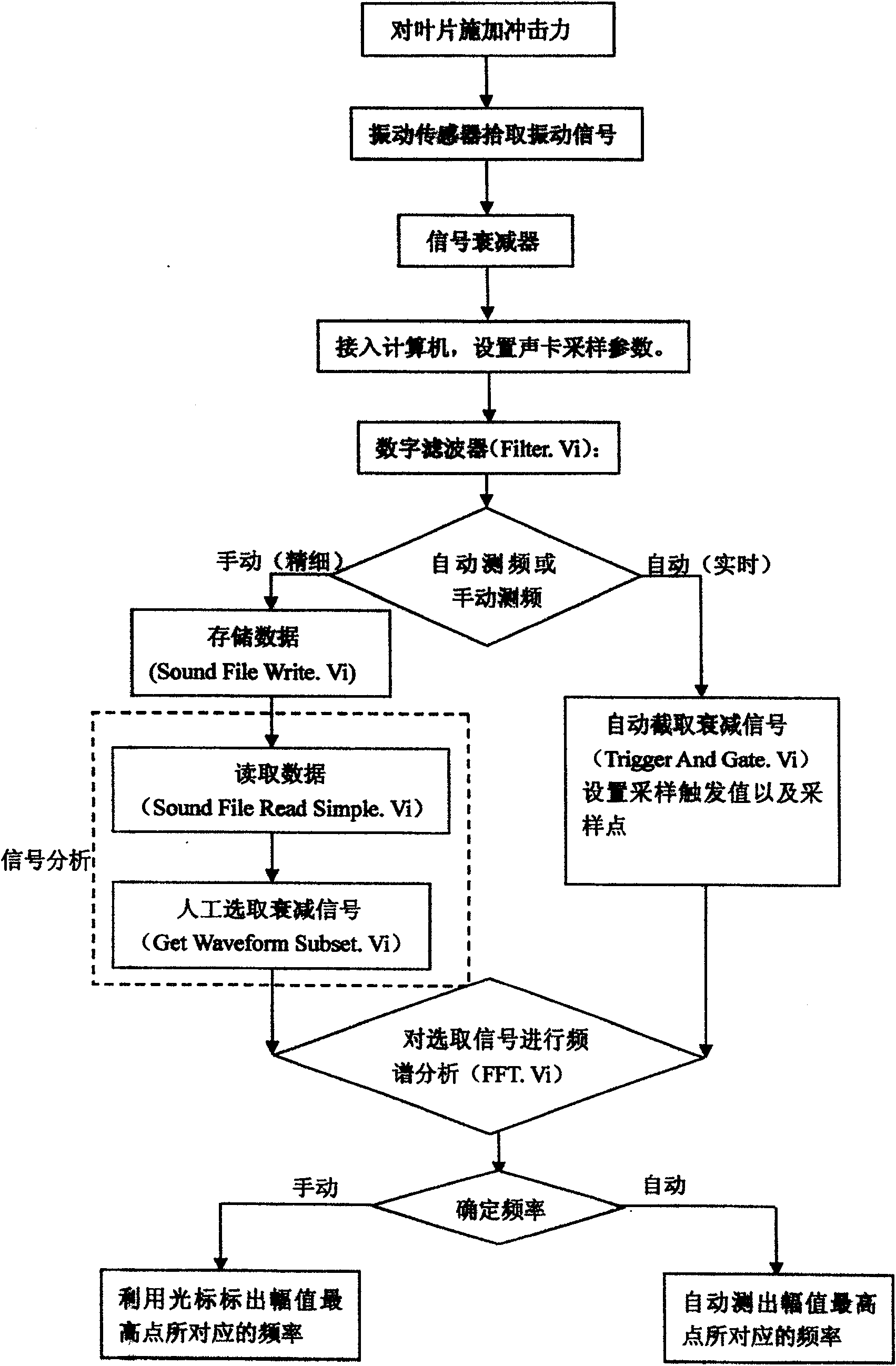

[0047] (1) Connection: Connect the vibration sensor and attenuator in turn, and enter the computer through the microphone interface.

[0048] (2) Initial setting: Turn on the frequency measurement system, and set the sampling frequency, sampling digits, sampling points, band-pass filtering range of the digital filter, trigger value and trigger sampling points of the sound card on the operation interface.

[0049] ① The sampling frequency is generally 4-10 times the frequency of the measured blade or structural component. Usually the frequency of the component to be tested is estimated in advance, and then it is judged based on the result whether the sampling frequency needs to be reset to ensure that it meets the requirements of signal processing. The default value is 2048Hz.

[0050] ②The number of sampling digits generally selects the default 16 digits, which can ensure the accuracy of sampling.

[0051] ③ The number of sampling points is related to the sampling frequency....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com