Testing method of contact heat resistance between circular section one-dimensional nanostructures

A nano-structure, circular cross-section technology, applied in the field of thermophysical parameter testing of solid materials, can solve the problems of high sample quality consistency requirements, easy damage or loss of samples, and reduced test success rate, so as to improve the test success rate and improve Measurement accuracy, effect of reducing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

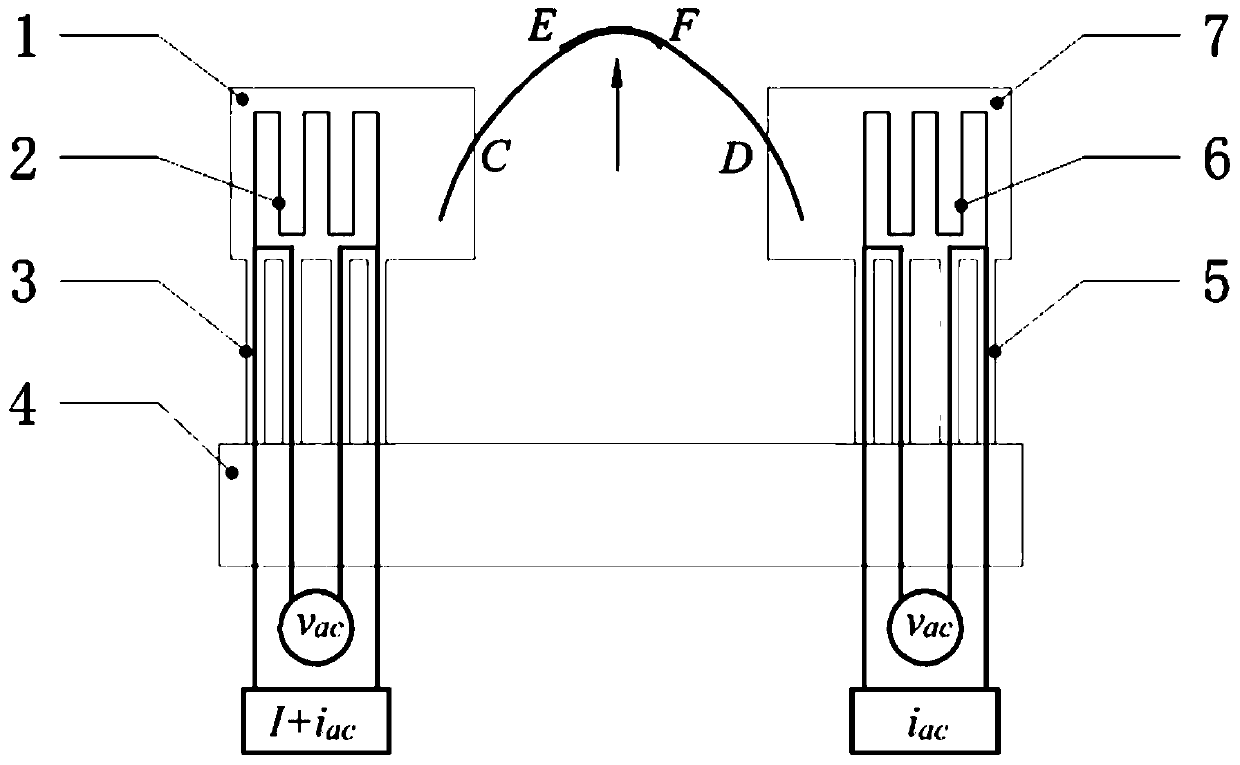

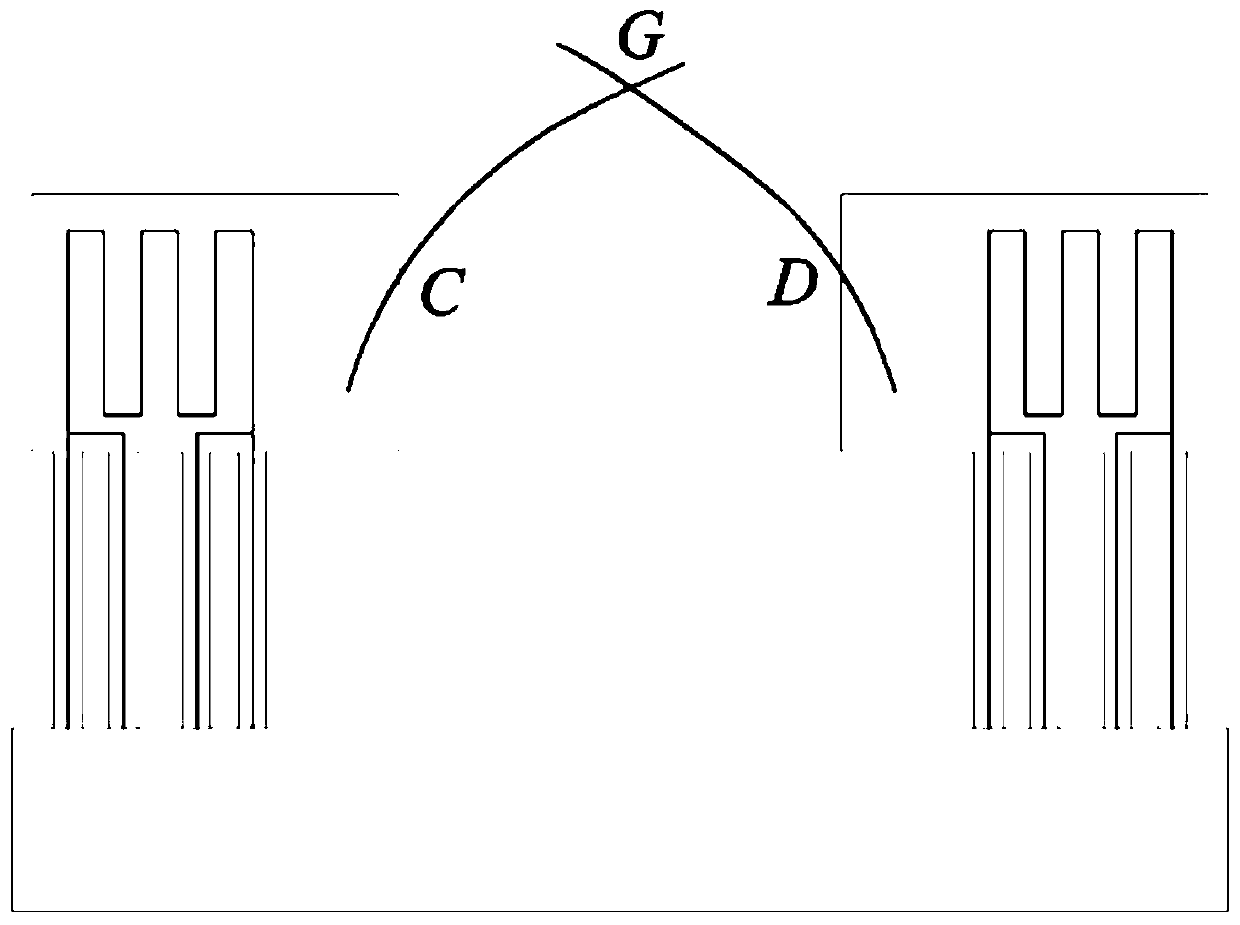

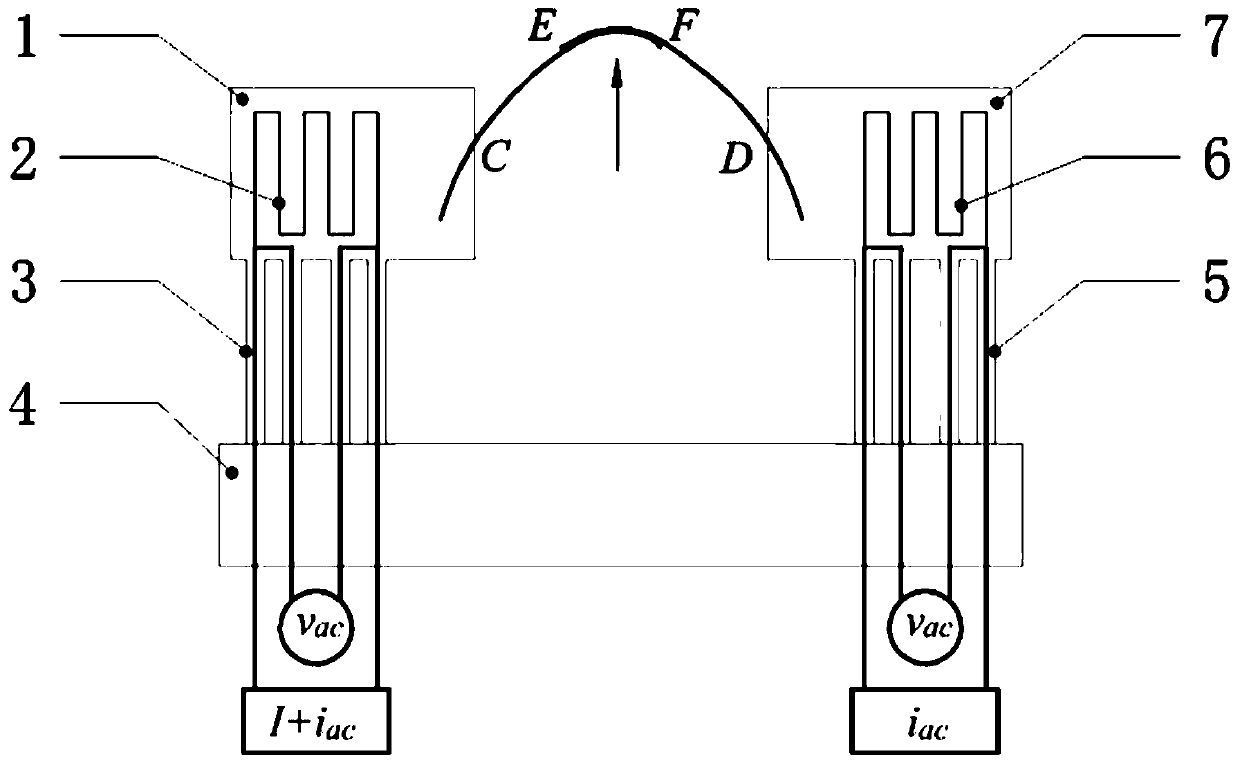

[0042] The test scheme for contact thermal resistance between one-dimensional nanostructures with circular cross-sections disclosed by the present invention adopts a thermal bridge method as a test technique. The present invention will be described in further detail below in conjunction with the accompanying drawings and implementation examples.

[0043] figure 1 The schematic diagram of the thermophysical properties of one-dimensional nanostructures tested by the thermal bridge method is given. The method uses a suspended micro-device prepared by MEMS technology, including a suspended heat source 1 and a heat sink 7 , a plurality of first suspension arms 3 supporting the heat source, a plurality of second suspension arms 5 supporting the heat sink, and a substrate 4 . The first microcoil 2 and the second microcoil 6 are made respectively on the heat source 1 and the heat sink 7, wherein the first microcoil 2 is used as a heater and a temperature sensor to heat the heat sourc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com