Solid coupling agent for portable ultrasonic liquid level detector

A technology of ultrasonic wave and couplant, applied in the field of couplant for ultrasonic liquid level meter, can solve the problems of no longer detection, damage to the appearance of the container, complicated operation process, etc., to avoid uneven application, improve accuracy, and repeat detection. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

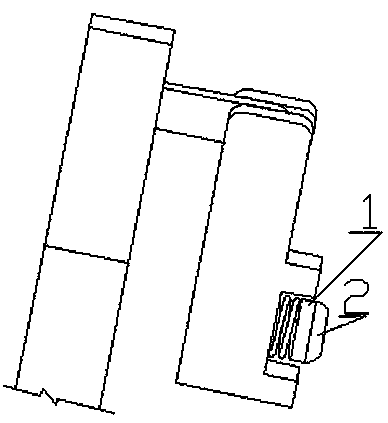

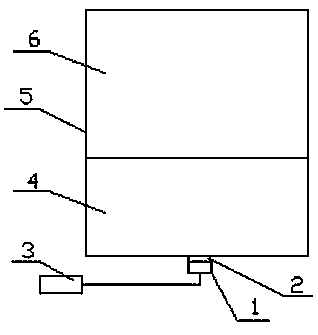

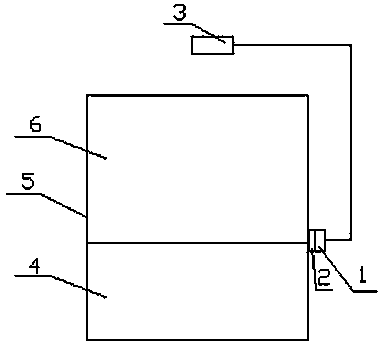

Image

Examples

Embodiment 1

[0027] A solid coupling agent for a portable ultrasonic liquid level detector, made of the following components in parts by weight: 90 parts of vinyl silicone rubber, 10 parts of gas phase white carbon black, hexamethylcyclotrisilazane and octamethyl 4 parts of cyclotetrasiloxane mixture, 0.5 part of dicumyl peroxide, and 0.8 part of azodicarbonamide.

[0028] The preparation method is: add vinyl silicone rubber, fumed silica, mixture of hexamethylcyclotrisilazane and octamethylcyclotetrasiloxane, and azodicarbonamide into the open mill in sequence, Botong 5 After the second time, the material is cut, and the dicumyl peroxide is added for re-milling, and then the thin pass is carried out, and it is parked for 26 hours, and the mill is used for re-milling, and the solid coupling agent is obtained by pressing out after being fully soft and smooth. .

Embodiment 2

[0030] A solid coupling agent for a portable ultrasonic liquid level detector, which is made of the following components in parts by weight: 100 parts of vinyl silicone rubber, 15 parts of gas phase white carbon black, hexamethylcyclotrisilazane and octamethyl 6 parts of cyclotetrasiloxane mixture, 0.8 part of dicumyl peroxide as the vulcanizing agent, and 1 part of azodicarbonamide.

[0031] The preparation method is: add vinyl silicone rubber, fumed silica, mixture of hexamethylcyclotrisilazane and octamethylcyclotetrasiloxane, and azodicarbonamide into the open mill in sequence, Botong 5 After the second time, the material is cut, and the dicumyl peroxide is added for re-milling, and then the thin pass is carried out, and it is parked for 24 hours, and the mill is used for re-milling, and the solid coupling agent is obtained by pressing out after being fully soft and smooth on the surface. .

Embodiment 3

[0033] A solid coupling agent for a portable ultrasonic liquid level detector, made of the following components by weight: 120 parts of vinyl silicone rubber, 20 parts of gas phase white carbon black, hexamethylcyclotrisilazane and octamethyl 8 parts of cyclotetrasiloxane mixture, 1 part of dicumyl peroxide, and 1.2 parts of azodicarbonamide.

[0034] The preparation method is: add vinyl silicone rubber, fumed silica, mixture of hexamethylcyclotrisilazane and octamethylcyclotetrasiloxane, and azodicarbonamide into the open mill in sequence, Botong 5 After the second time, the material is cut, and the dicumyl peroxide is added for re-milling, and then the thin pass is carried out, and it is parked for 30 hours, and the mill is used for re-milling. After being fully soft and smooth, the surface is pressed out to obtain the solid coupling agent. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com