Cooling and reflux device of evaporated water for lead acid accumulator free of liquid feeding

A technology of acid storage battery and reflux device, which is applied in the direction of lead-acid storage battery, transfer electrolyte device, battery pack components, etc., which can solve the problems of lead-acid battery drying up, shortened service life, gas leakage, etc., and eliminate the need for liquid addition Trouble, reduce water loss, increase the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The structure proposed by the evaporative water cooling reflux device of the liquid-free lead-acid storage battery of the present invention will be described in detail below according to the accompanying drawings.

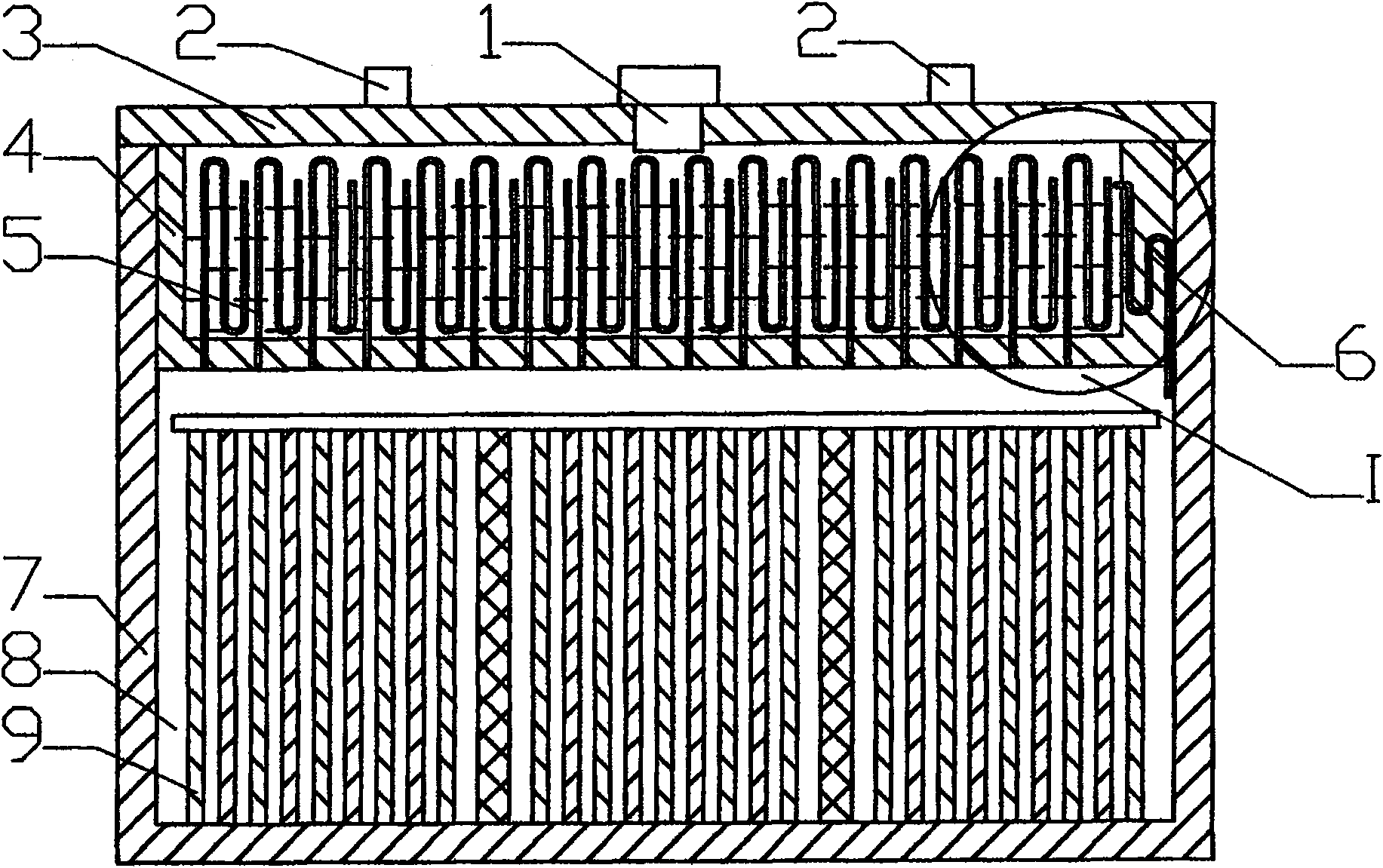

[0016] Such as figure 1 As shown, it includes a battery box 7 with an acid solution tank 8, a positive and negative plate group 9, a box cover 3 with a positive and negative terminal 2 on it, a one-way safety valve 1 on the box cover 3, and it also has a built-in The condensation reflux tank 4 of the cooling liquid 10, the condensation reflux tank 4 is fixed on the inner surface of the box cover 3 and placed above the acid solution tank 8 in the battery box 7, and the outer wall of the condensation reflux tank 4 is closely matched with the inner wall of the battery box 7; The tank 4 is equipped with an array of siphon pipes 5 covering the whole tank and an overflow pipe 6 leading to the acid solution tank 8 .

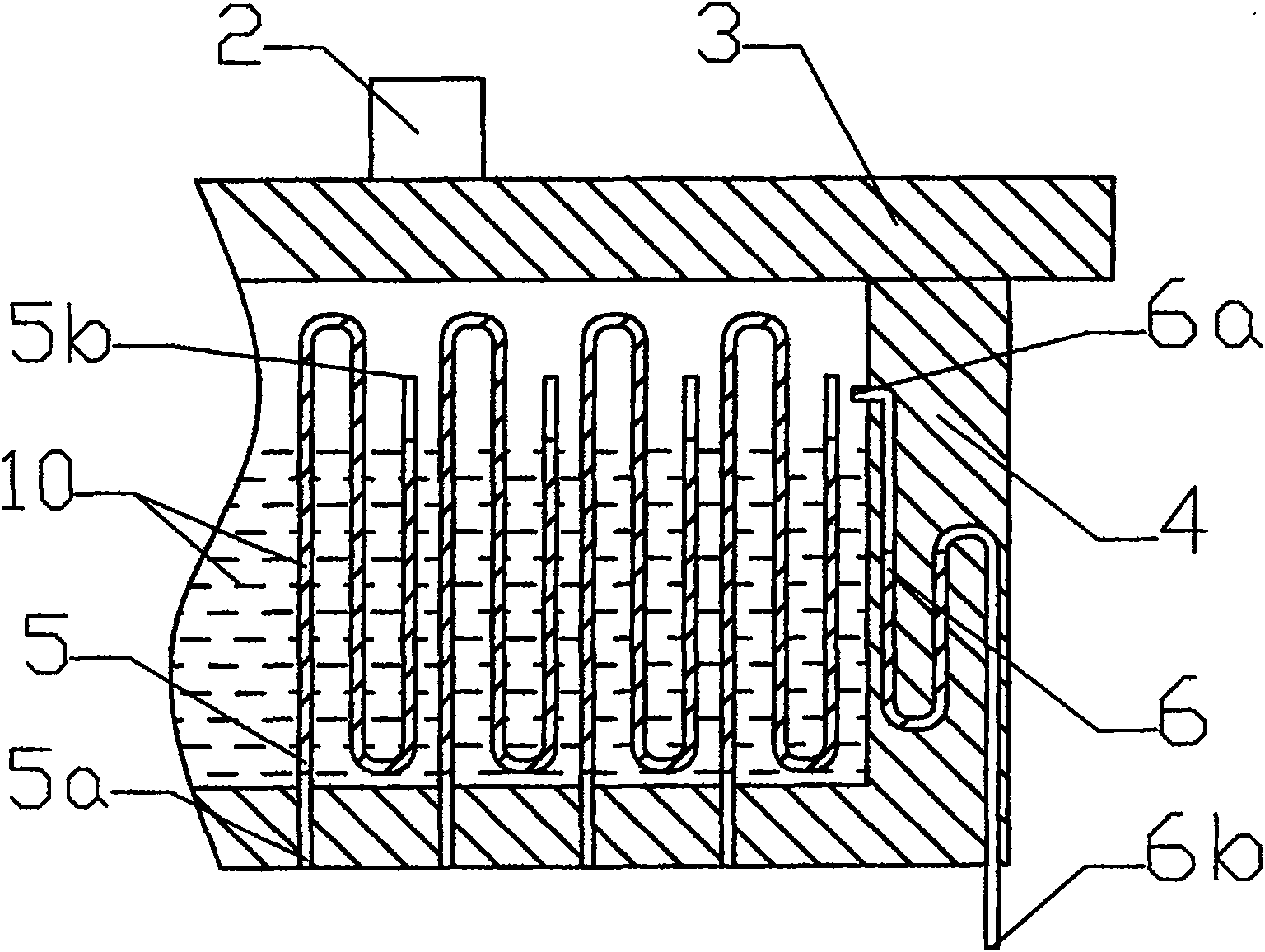

[0017] Such as figure 2 Shown, siphon pipe 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com