Self-mounting type bucket base with oil storage chamber

A barrel-type foundation and oil storage tank technology, applied in the field of marine engineering, can solve problems such as difficulty in meeting platform stability requirements, achieve the effects of reducing installation costs, avoiding operating costs, and improving structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

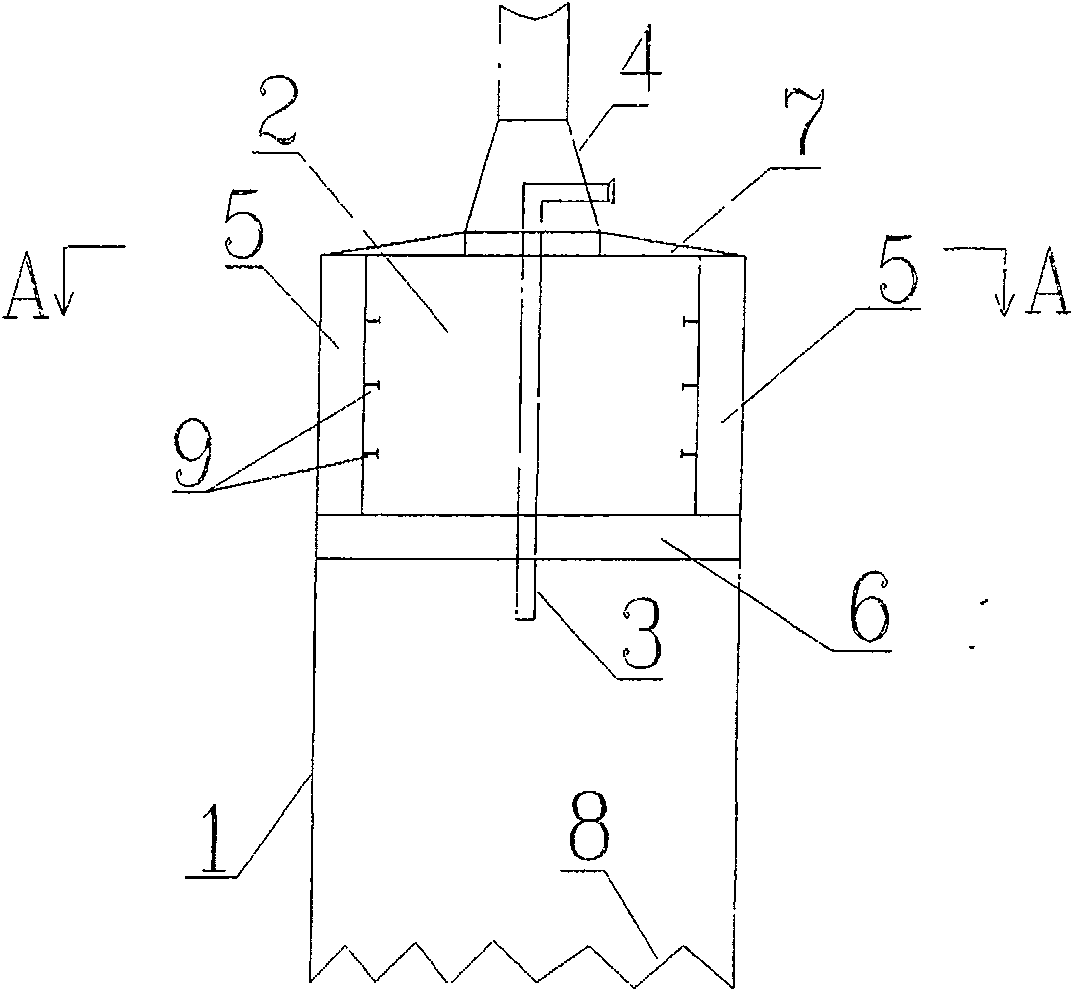

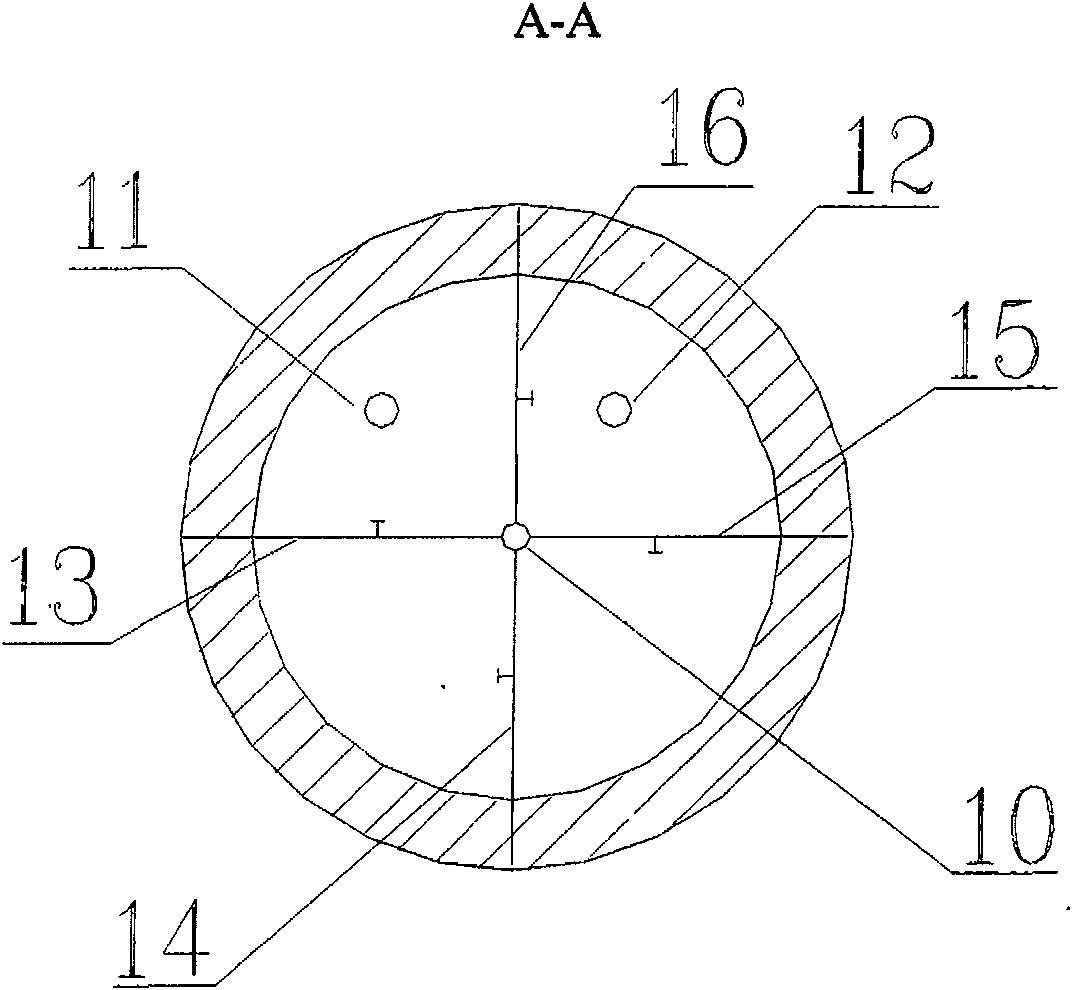

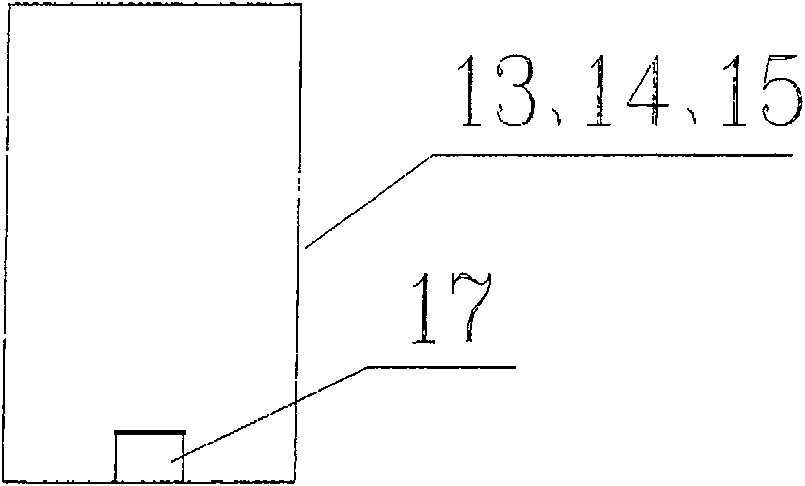

[0024] The bucket foundation of the self-installing offshore mobile platform with an oil storage tank of the present invention is composed of an oil storage tank 2 , an anchor barrel 1 , a column 4 and a ventilation pipeline 3 . There is an airtight oil storage tank 2 on the upper part of the barrel-shaped foundation, which can be divided into multiple sub-compartments through the sub-bulk walls 13, 14, 15, 16 to meet the strength requirements of the structure. Its function is to provide self-floating capability for barrel-type foundation towing under no-load conditions; it can be used as a ballast tank during the installation phase; during the platform production phase, it can realize the oil storage function by filling the tank with oil, saving round-trip transportation costs. Oil inlet and outlet holes 11,12 are arranged on the top plate of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com